Lost control over your inventory? Here are three simple ways to regain control of your manufacturing inventory management once and for all.

Face it, there are probably a hundred things you’d rather do than inventory management, but it’s a crucial component in your manufacturing pipeline. When you have a proper inventory management solution, you prevent stockouts, improve recordkeeping, and free up warehouse space for more materials and products. Let’s start with how inventory management has changed over the years:

Advanced Sales Forecasting

Sure, there was analytics ten years ago, but it was nothing like the tech we have today. You can now track every aspect of your sales campaigns and forecast demand with the latest predictive analytics. You no longer need to make complicated calculations based on last year’s sales figures. Today, the newest software does all the hard work for you to manage other aspects of your business without breaking a sweat.

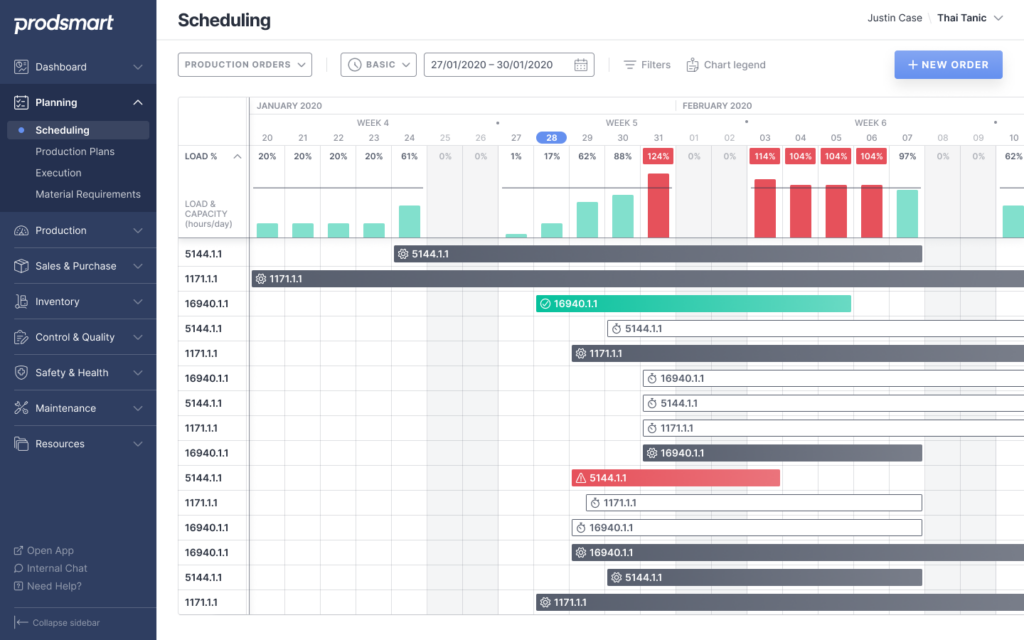

Manufacturing execution systems like Fusion Operations optimize inventory management with the latest metrics and key performance indicators. You can track the metrics that provide your manufacturing business with the most value, such as anticipated demand, and then make decisions based on this data. With real-time data, you can analyze shop floor operations such as materials, machines, wasted time, labor, costs, and more with a click of a button or swipe of a finger.

Taking Control of Your Inventory

Follow the below tips to take control of your inventory once and for all:

1. Involve Your Whole Team

Don’t manage inventory by yourself. Inventory management is a team effort, and everyone needs to be on the same page — production workers, supervisors, managers, etc.

Create an inventory checklist and distribute it to all members of your team. You can do this via email or by printing out copies of your checklist and placing them around your building. Create a list of “golden rules” — guidelines that everyone must follow. For example, if someone takes something from your warehouse, they need to document it.

2. Work With Suppliers

Your suppliers provide you with the raw materials and other items you need to carry out day-to-day manufacturing tasks, so keep in contact with them regularly.

Imagine if you discovered a particular material had been discontinued because you hadn’t talked with your supplier recently. It could disrupt operations in your business; this is why communication is so important. Subscribe to suppliers’ email lists and check in with them regularly — don’t wait until you place your next monthly or quarterly purchase order.

3. Digitize Your Inventory

This one is, perhaps, the most important. If you want to compete with your rivals, manual inventory methods just won’t cut it. You need a reliable digital system that automates many of the processes associated with inventory management that documents stock control and other tasks.

Using a manufacturing execution system like Fusion Operations could provide you with a return on your investment as you digitize your inventory processes and generate valuable insights into your product and material databases. Nearly every modern business is using software like this. Research shows that 25 percent more retailers and manufacturers are investing in better warehouse management technology.

Are you ready to take control of your manufacturing inventory management? Get started with Fusion Operations today!