In the ever-evolving world of design and engineering, flexibility and efficiency are key. Autodesk Fusion provides powerful tools to manage complex designs and configurations. We’ll explore how to effectively use configurations and the derive feature in Fusion, ensuring you can maximize the potential of your designs.

Understanding configurations

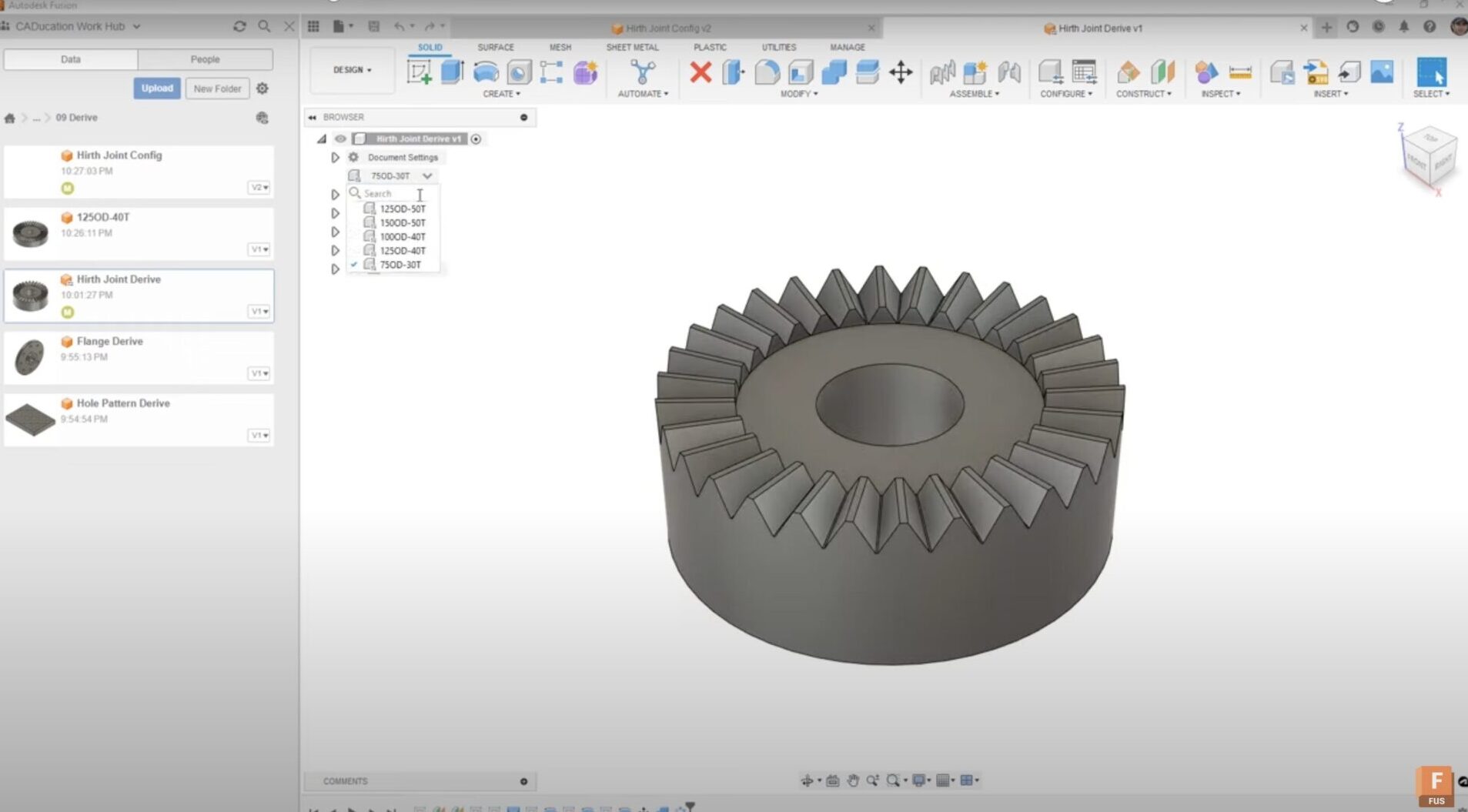

Configurations in Fusion allow you to create variations of a similar design element by adjusting key parameters. For instance, let’s consider a Hirth joint. A Hirth joint can be designed with various outside diameters and different numbers of teeth. Configuration tables in Fusion allow you to easily manage these variations. By using these tables, you can quickly switch between different design options for the Hirth joint, such as changing its size or the number of teeth, without creating entirely new designs from scratch.

The role of derive

You might wonder why you need the derive feature if you have configurations. Generally, you don’t need to use derive if you have a component with configurations, as you can select the desired configuration when inserting it into a new design. However, derive becomes essential when you need to make additional changes to a configured component after exporting it.

Practical application

Let’s walk through the process with an example. We have a Hirth joint with various configurations based on the outside diameter and the number of teeth. To derive from these configurations effectively, follow these steps:

- Name Your Configurations: Ensure your configuration names are descriptive, reflecting critical elements like part numbers or specific geometric changes. This makes it easier to manage and reference configurations later.

- Using Derive with Configurations:

- Select Derive Objects: Go to the derive function and select the top-level component that contains your configurations. This component includes bodies, sketches, construction geometry, and parameters used in the configurations.

- Expand Parameters: Make sure to bring in parameters from your component, ensuring all relevant information is carried over.

- Making Additional Changes: Once derived, you can make modifications without affecting the original configured assembly. For example, you might add a chamfer to an edge. Save this new design with a descriptive name reflecting the configuration, such as “100OD-40T”.

- Insert the Derived Component: Insert the modified component back into your assembly, placing it in the correct location and orientation. This allows you to integrate specific configuration changes seamlessly into larger designs.

Common pitfalls and solutions

It’s crucial to understand the different options and potential mistakes when using derive with configurations:

- Selecting Bodies Instead of Components: If you select only the body instead of the top-level component, the derive process will not carry over configuration names or parameters. Always select the top-level component to ensure all necessary information is included.

- Using Derive Component Incorrectly: Selecting derive component without the correct hierarchy can lead to missing configuration names and parameters. Ensure you follow the proper method to retain all relevant details.

Recap and Best Practices

To summarize, the ideal method to derive from configurations involves:

- Selecting derive objects and the top-level component.

- Ensuring all configurations and parameters are carried over.

- Making necessary modifications without affecting the original assembly.

Configurations and derive in Autodesk Fusion offer powerful ways to manage and modify complex designs. By understanding and correctly applying these features, you can enhance your design process, making it more flexible and efficient!