Saunders Machine Works (aka NYC CNC on YouTube) recently shared a comprehensive guide on how to mill a hemisphere using Fusion 360. There are so many ways to go about milling hemispheres in Fusion 360, including single operation or multiple operation workflows, and each method yields a slightly different surface finish. Milling hemispheres isn’t a super difficult thing to do, but it’s important to know your options and the pros and cons of each method before starting your next project.

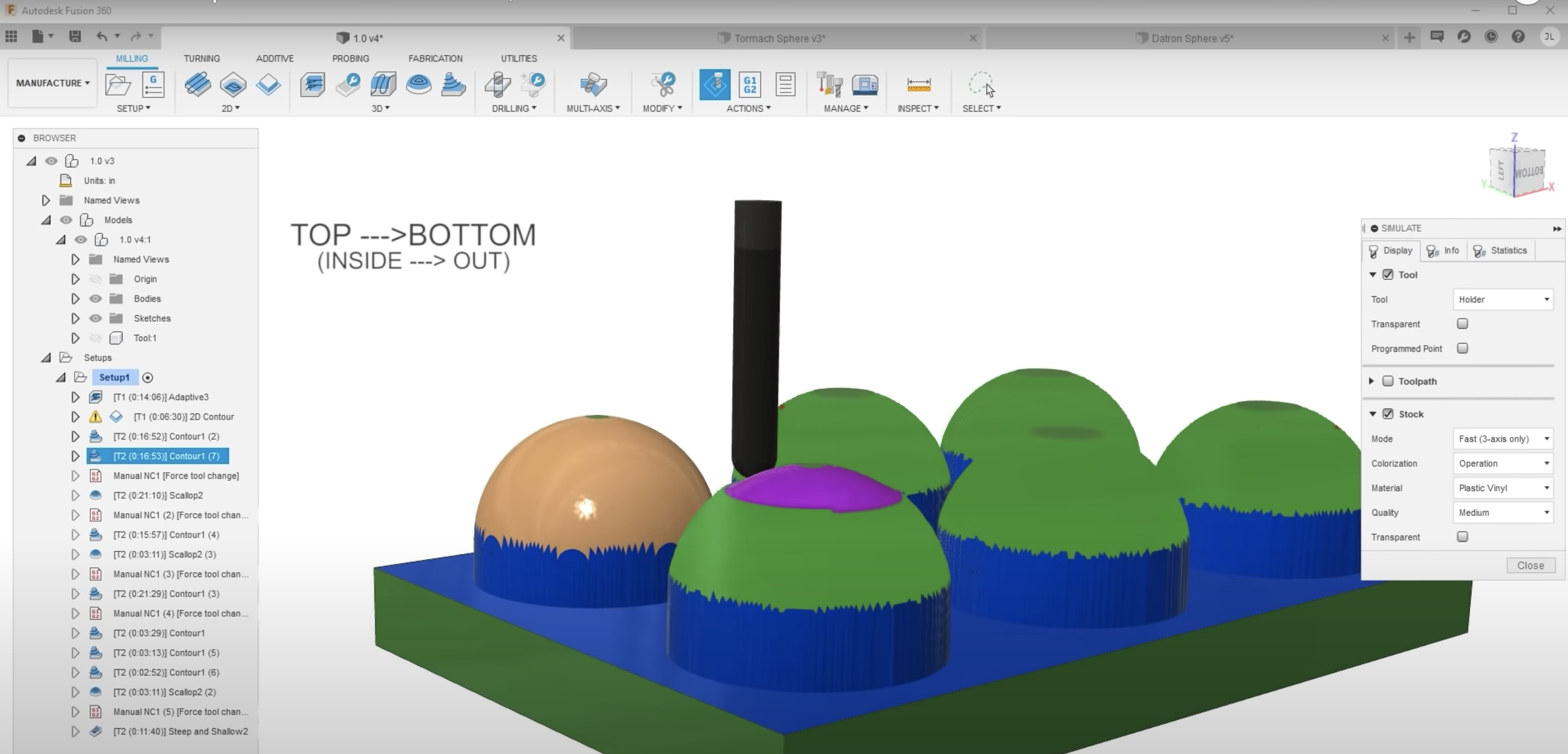

In this video, Saunders Machine Works does a deep dive into a few different processes and tests them each on the Tormach 1100MX and the DATRON Neo. The side-by-side comparison between the two is pretty epic and is worth a watch in and of itself if you’re curious to see what each machine is capable of. At the end, they bring together the knowledge they’ve gained throughout the video to mill one final hemisphere with the goal of achieving the best possible surface finish.

Fusion 360’s Manufacturing Extension includes Steep and Shallow functionality, which makes it easy to machine parts with complex surface geometry (such as a hemisphere) in a single toolpath. You can subscribe to the Manufacturing Extension directly through Fusion 360, so what are you waiting for? Try out Fusion 360 and the Manufacturing Extension today.