Configurations in Autodesk Fusion are an innovative feature to streamline your entire product development process. Whether you’re a seasoned user or new to Fusion, configurations offer a way to manage multiple design variations within a single model file, significantly reducing time, effort, and risk across your entire product development process.

This feature goes beyond the design phase of product development. It’s a holistic feature that also benefits the prototyping, electronics design, and manufacturing stages, bringing a new level of adaptability to your projects.

We’ve put together this article to answer over 20 of your most frequently asked questions about configurations. It’ll help you understand basic configuration features and see how to best leverage them in your projects moving forward.

What is a configured design (CD)?

A configured design (CD) is created when a standard design is saved with data in the configuration table. The standard design is converted into a configured design, which will be used for all future saves. The unconfigured, standard design is still accessible via version history.

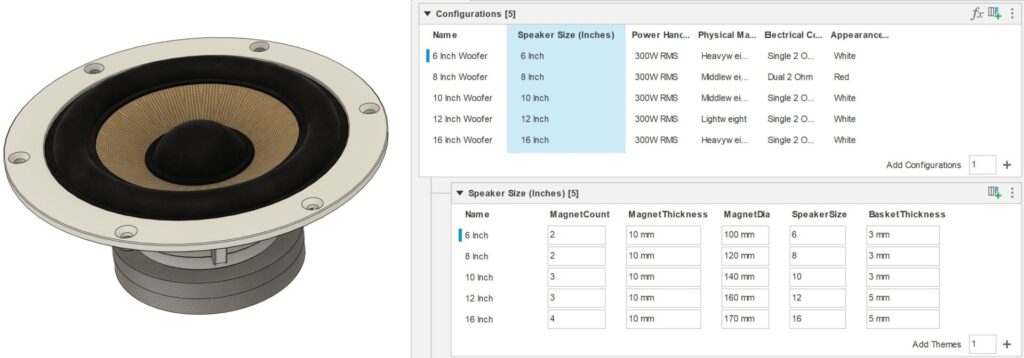

What are theme tables? How can I use theme tables?

Theme tables allow you to combine more than one parameter or aspect into one choice for the main configuration table. Theme tables are created below the main configuration table with the aspects you select.

For example, if you’re creating a kitchen cabinet that can be configured with or without a door, you may want to add suppression of the hinges and handles to a theme table with the door. That way, they can all be condensed into one choice for the top table rather than having all three aspects as columns and choices in the main table. Essentially, you can combine them into one choice; door or no door.

Appearances and materials are automatically added to a theme table when configured. Any material or appearance that is currently in the design can then be added as a row to the theme table. This will create a drop-down choice for those appearance or material options in the main Configuration Table.

How do you use inserted or cross-referenced (XREF) configured components to drive parts of a new model?

The workflow is almost the same as the one you would use for any XREF with just a few differences. Normal workflows like projecting an edge from the XREF to the new model will function as always. If all the various configurations share that same edge or face reference (despite size or location variance between configurations) the parametric “recipe” will remain intact.

How do you manage the assembly process within configurations?

When inserting a configured XREF you can pick the Configuration. The other configurations are available via a right-click command if you need to change it.

You can make a new configuration table that gives you access to the configurations of the design you are inserting by configuring the “insert” of the part in the timeline. This is a configured assembly.

For now, there are limitations for edit-in-place workflows regarding references such as assembly contexts. You can learn more here.

Is it possible to bring parameters from configured designs into another?

The easiest way to reference parameters in configured assemblies is to project geometry and use it as a sketch reference. An additional way may be to create a dummy design with parameters that are then derived into the various Configured Designs.

How do I share configured assemblies?

Single-level configured designs (CDs) can be shared using an export and share link. The result will be the same as from where they were exported. Configured assemblies or multi-level CDs have some limitations on export. For example, a CD that has a “configured insert” (references another CD in a column) cannot be shared as a CD. It can only be shared as an individual configuration.

How does versioning work with configurations?

Configured designs (CDs) and configurations may not add versions at the same intervals. The CD version can be seen in the data panel, configuration versions will only be seen when they are inserted into an assembly.

On save:

- The CD gets a new version (v1 -> v2 e.g.)

- If a configuration (row) is changed in any way, it gets a new version. If it is not changed, the version does not increment.

- For example, if a fillet is suppressed in c3, and the only thing changed in that save was an edit to that fillet, configuration 3 will not move to v2.

How do mathematical operators and conditional statements work within the configuration table?

The configuration table accepts mathematical equations and conditional logic statements just like the parameters table. This means you can create logic that differs between configurations easily by configuring the parameter you wish to create logic for and entering that logic where you would normally enter a value. Fusion will highlight the equation as black once the equation is valid.

Learn more about how Fusion handles logic here.

How do surface tools work with configurations?

The tools that come under the surface tab react to configurations in the same way as the solid tools because most of them are parametric and therefore have values associated with them that can be configured. For example, the length and taper angle of a surface extrude.

Otherwise, you can toggle suppression of a feature if it has no value associated with it and if it appears in the timeline. For example, if you want to configure surface sweeps between configurations, you can create more than one sweep and toggle whether they are active for each configuration.

How do I configure sheet metal and sheet metal rules?

You can configure sheet metal specific tools like flange and rip just like any other design tools that are driven by parameters or that appear in the timeline. Additionally, you can configure sheet metal rules and have the rules change between each configuration. To do this you must create the sheet metal rules you wish to have as an option in your configuration first. To configure those rules once they are created, click on the sheet metal component in the browser when in configuration mode and select sheet metal rule. This will create a theme table where your configurable sheet metal rules will reside.

Learn more about creating sheet metal rules here.

Note: Sheet metal components that are created using the “convert to sheet metal” workflow cannot have their sheet metal rules configured at this time.

How do plastic tools and plastic rules consume configurations?

The plastics specific tools will behave like any other design tool and will be configurable via the values that drive them. However please bear in mind that configuring these will overwrite the automations provided by the plastic rules.

You may also configure the plastic rules and have them change between configurations by clicking on a plastic component in the browser and selecting “plastic rule”. This will create a theme table where your configurable plastic rules will reside.

To do this you must create the plastic rules you wish to have as an option outside of configuration mode before they will appear in your theme table.

Learn more about configuring Plastic Rules here.

How do configurations work in the animation workspace?

Like most of the workspaces outside of design, the active configuration can be changed via the configuration drop-down menu in the browser at the top left of the canvas.

Once a configuration is active, its components can be transformed as usual, and exploded views will be kept separate between configurations provided the components have changed. Common components will stay exploded between configurations.

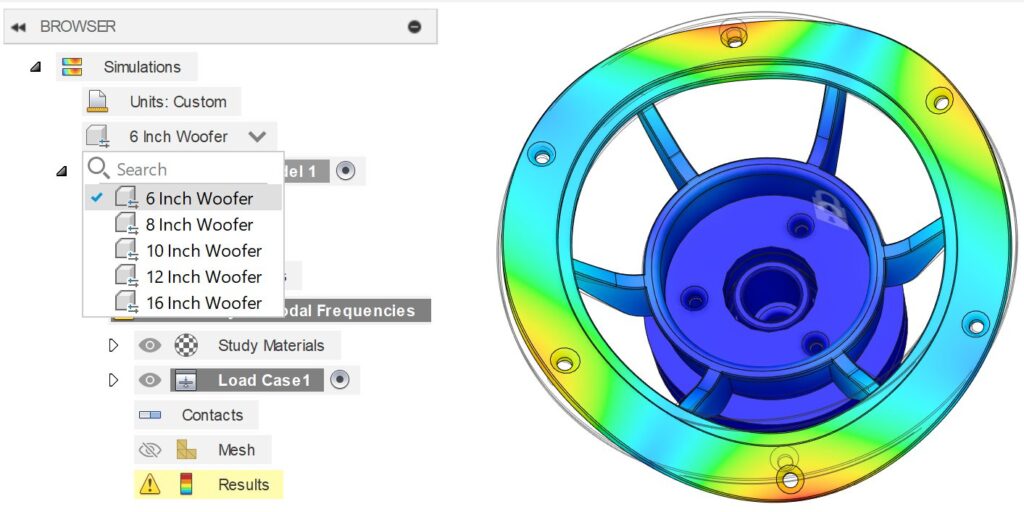

How do simulations consume configurations?

The simulation workspace will consume configurations in a comparable way to the other workspaces. There will be a drop-down menu in the browser that allows you to choose the active configuration. The behavior will then be the same as if you were working on a normal, unconfigured part. Simulation data will be saved to that configuration and will be accessible whenever that configuration is active.

When you switch to a new configuration, a new study needs to be set up and run from scratch. Fusion will not try to guess how you want to simulate a new configuration.

How does generative design deal with configurations?

The generative design workspace will consume configurations in a similar way to the other workspaces and be most like the Simulation workspace. There will be a drop-down menu in the browser that allows you to choose the active configuration. The behavior will then be the same as if you were working on a normal, unconfigured part. Generative design data will be saved to the active configuration and will be accessible whenever that configuration is active.

When you switch to a new configuration, a new generative study will have to be set up and run from scratch. Fusion will not try to guess how you want to simulate a new study.

You could use configurations to set up multiple generative studies by creating your preserve and obstacle geometry in the Design workspace and configuring this geometry. Therefore, creating configurable starting points for your studies.

How do configurations work in drawings?

The drawings workspace consumes all data from the configuration. configurations can be changed via a drop-down in the browser or by right-clicking on a view.

What is the workflow for making the drawings for all the configurations of a part?

Once you’ve finished the drawing of your first configured design, you can simply switch to another configuration and “save as” to create a brand-new drawing, which will be saved separately from the first. Your views, dimensions, and tables will all be updated to match the new configuration. Multiple sheets are supported and updated with the new configuration.

Why do I need to “save as” when creating a drawing for a new configuration?

Each configuration must be in its own drawing file. Currently, there is only support for ONE configuration per drawing. When switching from one configuration to another, some dimensions may be deleted if they cannot be resolved due to missing geometry from one configuration to the next. Dimensions are not cached and will not regenerate if you switch to a configuration that would have the associated geometry again. Some minor adjustments may be needed to align dimensions due to varying part dimensions.

How do configurations get consumed in manufacturing?

There are two methods of consuming configurations in manufacturing, but it’s dependent on the top-down or bottom-up method. If it’s an XREF, you’ll need to go back to design and choose which configuration to activate. If it is all native to one file, the configuration button will be present in manufacturing.

What happens to my toolpaths if I switch to a different configuration?

Currently, all toolpaths will require recalculation. If features are simply missing due to configuration change, those toolpaths will contain errors.

Is there a way to ensure I do not have to recalculate every toolpath every time I switch configurations? Can I lock toolpaths?

Locking toolpaths will prevent them from needing to recalculate, but if the underlying geometry is no longer there, you’ll likely result in a scrap part. This could be useful for time-intensive toolpath calculations such as adaptive or blend. Use “protect” with caution!

Can I edit configurations directly from the manufacturing workspace?

You can (in some instances) activate different configurations and perform edits to them, in the context of manufacturing models. These edits do not flow back to the design space, as they are intended to be used for manufacturing purposes. WARNING! When a manufacturing model is active and you switch configurations, it WILL update the manufacturing model to the active configuration. Ensure you activate the “model node” before switching configurations to prevent a model override in the manufacturing model.

How does rendering work with configurations?

The rendering workspace consumes all data from the configuration including geometry and appearance. Configurations can be changed via a drop-down in the browser.

Do environments stay the same between each configuration?

Environments remain the same when switching configurations to retain consistency.

Ready to explore configurations in Autodesk Fusion?