This post is also available in: Italiano (Italian) Deutsch (German)

An interview with Jonathan Ward, CEO of ICON, about how he designs vintage-inspired vehicles with Autodesk Fusion 360.

Who doesn’t look twice when a vintage car drives by? There’s a retro-cool factor and the excitement of spotting something out of the ordinary on the road. But the actual driving experience? Well, that’s a whole other reality. Let’s just say it’s not always a comfortable ride.

Jonathan Ward, CEO of ICON, decided it was time for a new approach.

“In the early 2000s, we were seeing a huge attrition in traditional and legendary custom design, especially with luxury vehicles,” says Ward. “There was a demand for custom vintage cars. But once owners really drive them, it’s an entirely different experience.”

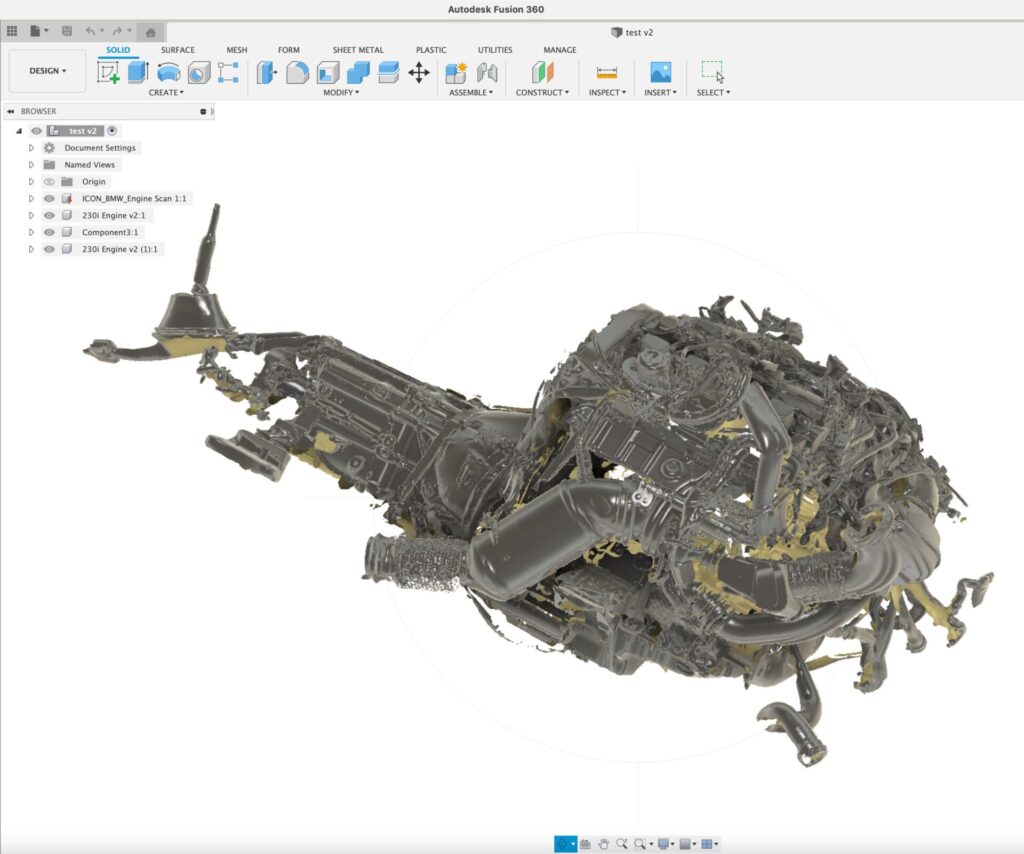

Ward used his passion for automotive design to launch ICON, a company that designs and produces some of the most creative vehicles in the world. Ward builds each ICON vehicle with a mixture of vintage parts and modern, bespoke parts designed in-house.

Merging modern tastes with the “heart and soul” of vintage

Ward wanted to bring the “heart and soul” of vintage to automotive elements like power windows and navigation to meet modern expectations. At the same time, he could deliver scalability beyond the one-off jobs that are especially prevalent with custom vehicle design.

“I wanted to truly evolve the user experience way beyond what the traditional analog approaches would allow,” Ward says. “I could also start to address the financial aspects and feasibility of our labor, make it more scalable, and improve the quality.”

Ward previously had years of experience designing for OEMs and starting and running TLC, now the nation’s leading Land Cruiser Service center. In partnership with his wife, they founded ICON. Since its early days, the company has expanded to a variety of models from the 1940s to the 1970s. Each ICON FJ model starts life as a vintage Toyota Land Cruiser (1960-1975), the ICON TR uses a 1947-53 Chevy Pick-Up, and the ICON BR begins with a 1966-1975 Ford Bronco.

“We recycle the vintage vehicle, and the original vehicle identification is maintained,” Ward says. “This also saves tremendous industrial waste, and we are reviving vehicles most people thought were at the end of their life span! Occasionally, special projects like our concept cars are scratch-built vehicles.”

Getting started with Fusion 360

Of course, technology is a key component to the design and manufacturing of these unique vehicles. Ward’s introduction to Autodesk Fusion 360 was unusual — it all started with his son’s passion for robotics in junior high school and an Instagram post.

“My son was really interested in pursuing a career in mechanical engineering,” Ward says. “I asked about it on our Instagram account and the responses were amazing. Autodesk was one of them.”

After a trip to the Autodesk Technology Center San Francisco and getting a glimpse at Fusion 360 back in 2016, Ward was excited to see how he could begin to incorporate it into his work. “We were getting pretty frustrated with Solidworks,” he says.

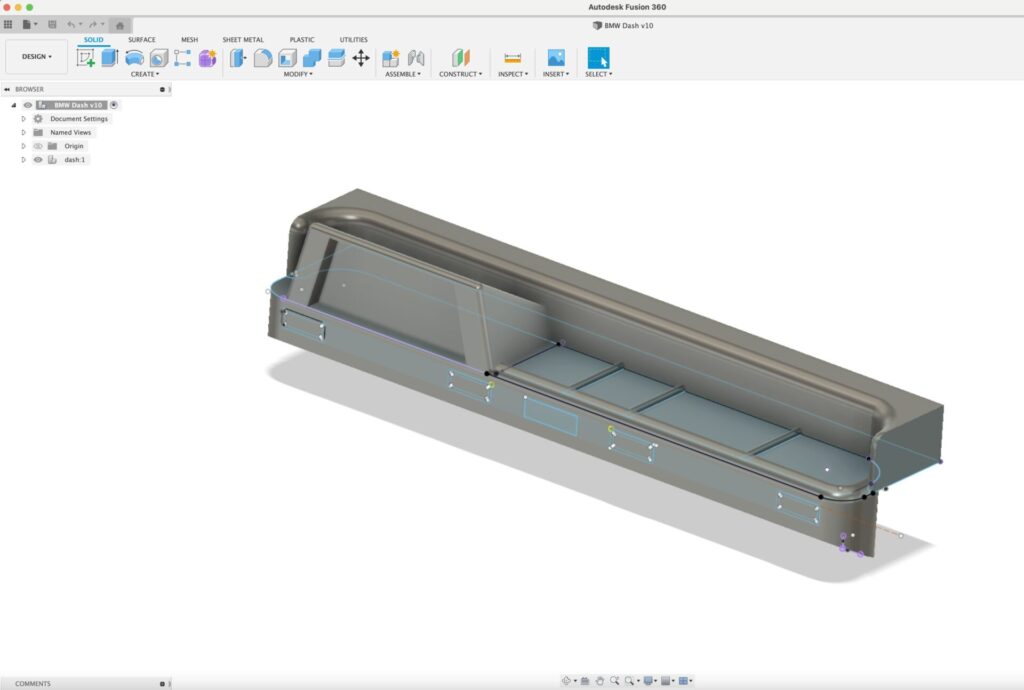

As Fusion 360 grew as a product and its capabilities expanded over the years, Ward was able to include it more and more throughout his design and manufacturing processes. Now, Fusion 360 is the go-to for a variety of components—whether it’s knobs, steering wheels, handles, grills, panels, you name it.

“Even the help chat function on the Fusion 360 platform is pretty impressive. It’s not just like, ‘Oh, here’s a link.” More like, boom, here’s the solution. They really get involved very quickly.”

Jonathan Ward, CEO, ICON

Moving forward with new projects and Fusion 360

Throughout the pandemic, ICON has been as busy as ever with multiple jobs. Like most industries, they’re still feeling the pinch of supply chain issues, tracking down the right materials, and labor shortages.

But Ward is continuing to innovate and dream big with Fusion 360. Right now, he’s looking into retrofitting EV systems into their internal combustion engine intended platforms.

He’s thinking ahead to his next venture, too. After designing a watch in Fusion 360 a few years ago, he’s now using the software in another unconventional way. This time it’s for handcrafted leather goods.

According to Ward, the leather goods industry is rife with paper-based processes and workflows. With Fusion 360, he can both protect his IP and easily produce one-to-one scale PDFs for manufacturing.

At the end of the day, Ward can use Fusion 360 for ICON or wherever his next passion project takes him.

“There are so many functionalities for different utilities we need,” he says. “It’s all in one package with Fusion 360. I can’t think of a competing product in the space that comes close to that.”