STS Technical Design showcases advanced manufacturing capabilities with Fusion 360, which offers a seamless workflow between design and material selection.

When you deal exclusively with big-name industrial customers and highly sensitive applications, it’s very challenging to market your capabilities. This was a particular problem for contract engineering firm STS Technical Design and one of their material providers, The Virtual Foundry, both of which are based in Wisconsin.

“We deal with a lot of proprietary work for customers in the aerospace and other industries, so we can’t really show our full offering to prospects,” says Benjamin Heard, project manager and additive manufacturing engineer for STS. “And The Virtual Foundry can’t even tell you who they sell to.”

As a result, the companies were looking for a way to highlight both the unique design expertise of STS and the innovative materials of The Virtual Foundry. Coincidentally, The Virtual Foundry had already been collaborating with Autodesk on Fusion 360, which helps unify design, engineering, and manufacturing processes within a single platform.

“Our contact within Autodesk had mentioned they were launching a new experience intended to make it easier for users who are new to 3D printing, or for anyone who is new to CAD,” says Tricia Suess, president of The Virtual Foundry. “When I mentioned this to Benjamin, the idea finally clicked.”

Rethinking the User Experience

What the companies came up with was a project that would serve a number of important objectives simultaneously.

First, it would put their collective talents on display, illustrating how the part design, material selection, and software could all work together seamlessly. At the same time, it would showcase the increasingly wide range of opportunities in advanced manufacturing as well as demonstrate how accessible these techniques have become, especially for startups and independent users.

“That’s what drove this project, trying to see this from a new user’s perspective as they experience a new platform and bring a more complicated product to life with 3D printing,” Heard says. “And we were able to do it with tools that are accessible to new users and experienced professionals alike.”

Heard was a completely new user, never working with Fusion 360 prior to the project. He learned how to use it from scratch, drawing on his many years of design engineering experience, of course, as well as the tutorials that come with the software and a few other online resources.

“Fusion 360 made it really easy,” he says. “I knew what I was looking for, and I was able to find the functions pretty easily. Normally it takes a lot longer to learn enterprise-grade CAD software. But it was actually fun and by the end of the project I could do most of what I would usually do.”

All that remained was figuring out what kind of product to bring to life.

Three Parts for 3D Printing

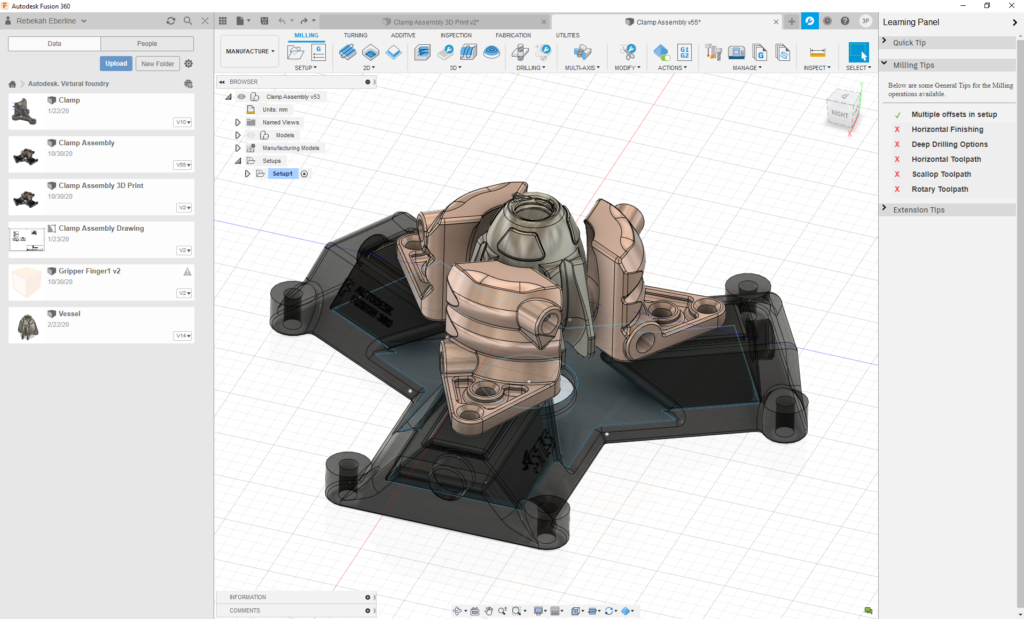

What the STS and The Virtual Foundry teams landed on was a three-part material handling solution. This comprised of a vessel, a water-cooled work holding device, and a simple base and carriage.

“A vessel like this could be used to hold cancer drugs, for example, or small samples of refined materials, or other substances in various applications,” Heard says. “It was designed to have a low center of gravity to avoid tipping.”

The vessel is made from Rapid 3Dshield Tungsten Filament from The Virtual Foundry, which has a printed material density of 7.5g/cc. This allows it to be used as a shielding agent in its printed state, without the need for any significant post-processing.

“We created this material as a nontoxic lead replacement, and in its green state, it can block radiation very effectively,” Suess says. “The filament uses the same plastic you would normally use for additive printing, but it’s essentially a binder for the metal. With our filaments, you can use an everyday 3D printer and heat-treat the part to remove the plastic, giving you a fully metal 3D-printed part.”

The grippers were designed to hold the vessel without marring its exterior surface, as well as offer cooling so the part can be kept at a relatively low temperature during final internal surfacing and threading cleanup.

“The water-cooled grippers ensure there is no deformation of the tungsten,” Heard says. “The grippers were sized up 10 percent prior to printing, allowing the copper filament to shrink during the sintering process.”

After sintering, the end result is a 99-percent-pure copper 3D-printed part, one that can withstand the rigors of work holding while allowing a cooling agent to pass through its internally printed channels. In addition, the grippers were printed without supports using minimum material.

Finally, the base and carriage are made from filament reinforced with chopped carbon fiber, which, when cooled, achieves virtually the same strength as aluminum.

Designing From Scratch

It took Heard approximately 24 work-hours to design these three parts, with input from his product development team, while also learning how to use Fusion 360.

“One capability that was really helpful was the ability to click on any number of faces and delete them,” he says. “The software removes and repopulates the feature, so I don’t have to go back in the feature tree and delete everything. The software smooths it out. Clients often ask to remove a feature that was requested early in modeling, and they don’t understand why it will take so much time to fulfill their request. This feature makes that problem much easier to solve.”

The intent of the project, however, was to show how the barriers to entry for advanced manufacturing are much lower than they were even a few years ago.

“Typically, to create parts like these, you would start by asking a tooling company to machine the work holding component out of a big block of copper, cross drilling six ways to get the cooling channels. Needless to say, that’s a much larger and more time-consuming project.”

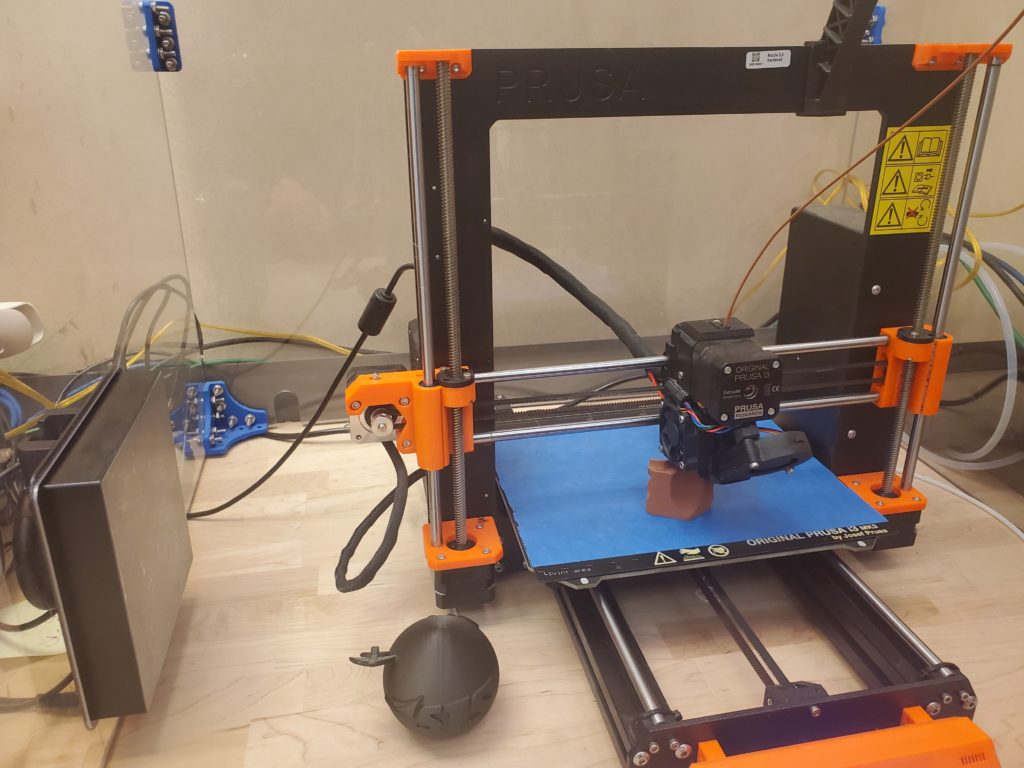

Using Fusion 360 and the innovative filaments from The Virtual Foundry, however, Heard was able to bypass this approach and create parts that can be printed on an inexpensive fused filament fabrication (FFF) 3D Printer, as opposed to industrial-grade metal 3D printers.

“You can print directly from your 3D design with Fusion 360,” Heard says. “That takes errors out of the process and you’re not spending time on drawings. Plus, if you have your own shop, you’re not occupying one of your CNC machines and you’re not creating a bunch of copper scrap.”

Putting It All Together

Suess notes that another advantage of this unique approach is the ability to quickly iterate on ideas during the design process.

“For this project, we could have printed a prototype of the grippers in PLA in a few hours, made changes to the design, and then reprinted in copper,” Suess says. “The whole approach makes collaboration very easy.”

Heard also notes that Fusion 360 simplifies versioning and file sharing, both of which streamline collaboration across teams. In this case, he shared his designs frequently with Autodesk for quick-turn feedback during the project.

“Normally we would have to create a very large file to send or use screenshots or user models, none of which is ideal,” he says. “But my contact at Autodesk had access to my group, so she could review the designs and even had permission to make changes. With other platforms, you can quickly get into a bad spot if multiple people are working on the same design. With Fusion 360 it was easy.”

This speaks to an important advantage of Fusion 360, which is that it brings together design, project management, and manufacturing capabilities in one application. Normally, each of these would require a separate software package. Using one platform is both more economical and more efficient. Changes from the design automatically update the rest of the workflow, eliminating the need to repeatedly export files from one tool and import them into another.

Most important of all, this approach establishes what Heard calls “a low-cost solution to an expensive problem.” In other words, the overall affordability of the design software, material, and 3D printer put the formerly cost-prohibitive world of advanced manufacturing at the fingertips of the average user.

“These are basically print and go parts,” Heard says. “It’s really spectacular that you can make parts like this. If you would’ve told someone a few years ago that you could make tungsten and copper parts this inexpensively, they wouldn’t have believed you.”

Ready to see how Fusion 360 can help your team collaborate and bring ideas to life faster? Download Fusion 360 today.