We recently released a new assembly tool, Ground to Parent, which is designed to streamline the assembly creation process in Fusion. We’ve also renamed the tool previously known as Ground to Pin. In this article, we’ll explain what these new changes are, why we made them, and how you can use them to create assemblies in Fusion more efficiently than ever.

Why have we added Ground to Parent?

Most of the time when we create designs, we don’t want the parts to be free to move relative to each other. And when they do, we want to define this movement specifically. Previously, the default behavior of Fusion was that all newly created components were completely free to move relative to the root component.

This could lead to situations where it was easy for an assembly not to be fully constrained and for unexpected movement to occur when a sub-assembly is inserted into a large assembly as an external reference. You had to use tools like As-Built Joints or Rigid Groups to fully constrain the assembly. This was time-consuming and made it easy to make mistakes, particularly when working with primarily external components which is the recommended workflow for building larger assemblies in Fusion.

What is Ground To Parent?

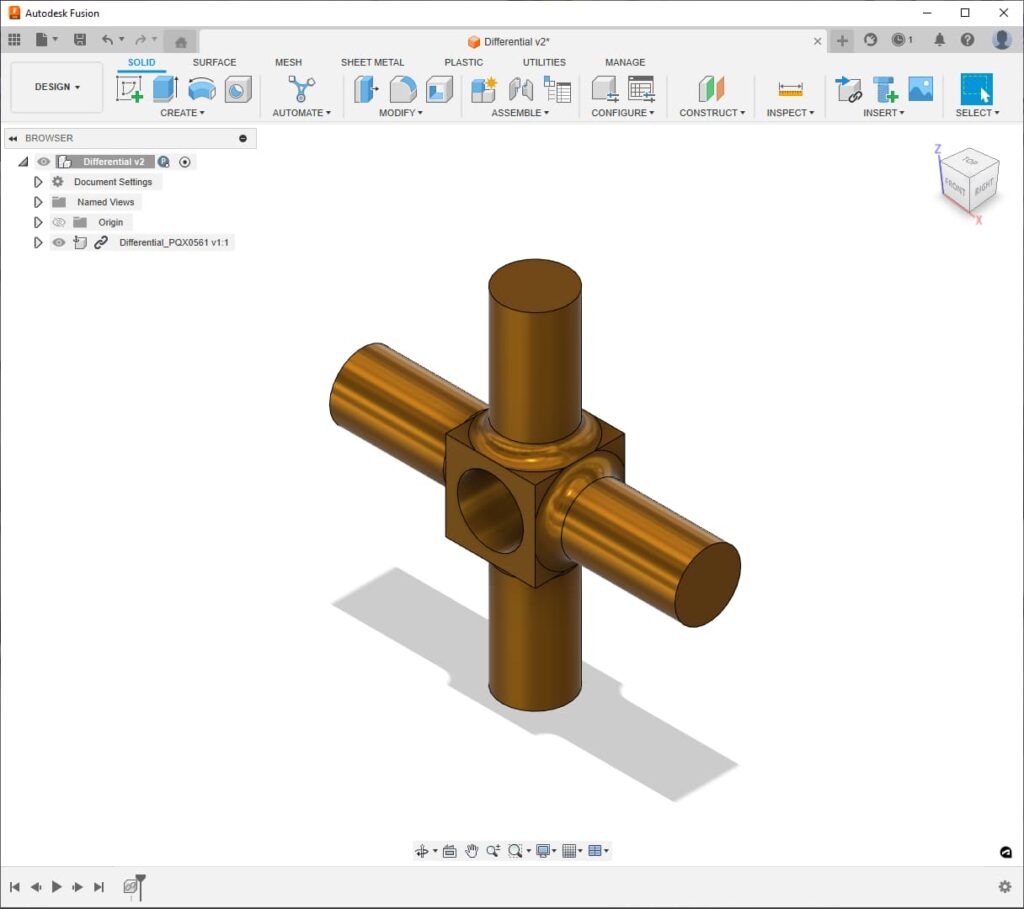

Ground To Parent defines an inherent rigid relationship between a child component and its parent component so that they move together. This works in the same way as an as-built-joint, by locking in place the coordinate systems of the two components, and is indicated by an anchor icon next to the component name.

The first component created at each layer of the sub-assembly, whether internal or externally referenced, will be Ground to Parent by default. This enables other components of the sub-assembly to be joined to it to form a fully rigid final assembly.

These component types are automatically Ground to Parent when you create them:

- The first component you create in a design

- The first child component of any component

- A component that you Copy and Paste or Paste New

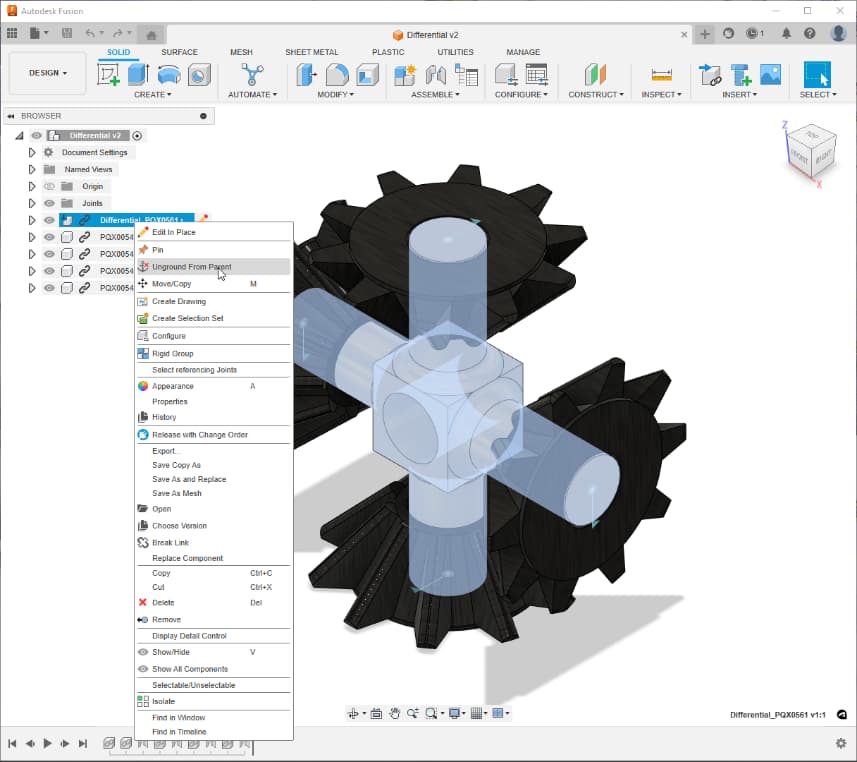

To unground a component, right-click the component in the Browser and select Unground From Parent. To ground additional components to their parent, right-click them and select Ground To Parent.

One of the advantages of using Ground to Parent is that it is extremely timeline efficient, reducing compute time and timeline clutter.

It is important to note that the Ground to Parent operation occurs at the point in the timeline when the component was created. If a child component has an existing assembly relationship and you ground it to its parent component, the child component will move back to its initial position. Ground To Parent will override commands later in the timeline that may have caused the component to move for any reason. This includes:

- Joints

- Rigid Groups

- Move

- Pin

- Capture Position

Set your preferences

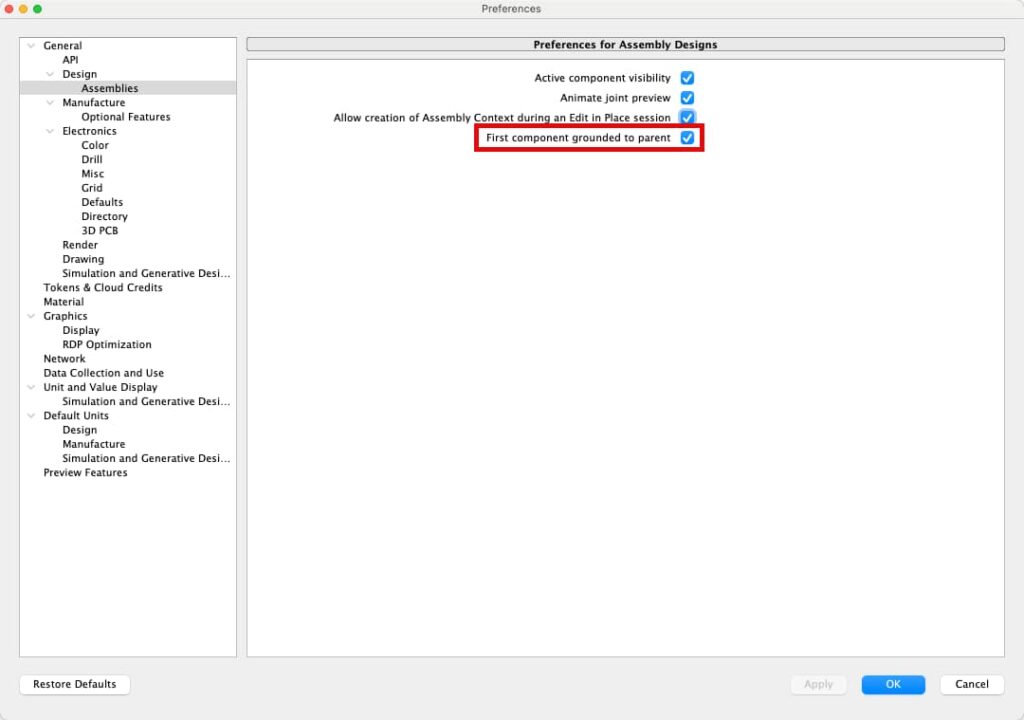

If you don’t want your components to be Ground to Parent automatically, you can change this default behavior. In the top-right corner, on the Application bar, click your Avatar and select Preferences. From the menu on the left, expand Design and select Assemblies. Uncheck “First component Ground to Parent.”

What about the old Ground command?

The tool previously known as Ground has been renamed to Pin, which we feel better describes its functionality. It’s also easy to identify by the pin icon. Its behavior has not changed, so if you used this tool before and want to keep doing so, you can continue to work in the same way uninterrupted.

One key limitation of the Pin tool is that it applies to the local design only and will not continue to apply if the assembly it’s used in is inserted into another design file as an external reference.

Improve your Fusion assembly workflow today

Ground to Parent is a tool implicitly designed to tame uncontrolled

disconnectedness in Fusion assembly designs and to enable larger assemblies to be built using external references without running into unforeseen issues. It has also been designed to be extremely timeline and compute efficient to improve large assembly performance.

If you have any thoughts about this new feature or Fusion assembly workflows in general, we’d love to hear from you in the comments.