& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

6 min read

The Fusion Factory Experience is back once again, and we can’t wait to show you what we have in store for this year’s event.

The Fusion Factory Experience started at AU 2016 as a way to give attendees a hands-on experience of the concept-to-production process on the Autodesk Fusion platform. Every year since, our team has designed, developed, and produced a brand-new consumer product to share with you all at Autodesk University. From redesigns to entirely new concepts, we’ve done it all. This year, we are thrilled to return with the Autodesk Keypad V2.

Last year we introduced a keypad based on the Adafruit Macropad, that was fully customizable to fit the needs of our most popular Autodesk products. It has 12 keys, a digital encoder, and an OLED display. When using the keypad you could effortlessly scroll through different product programing. This meant you could use the encoder to cycle through programming where the commands were all specifically tailored to each product. The process behind developing the keypad included many manufacturing methods like additive, CNC, and injection molding.

We chose this product for many reasons. It’s easily programmable with ever-growing code libraries, and with the Raspberry Pi RP2040 Chip + 8MB Flash memory, the sky’s the limit for what this thing can do.

This year we are excited to announce that we are back and better than ever with a sustainable redesign of the Autodesk keypad. It’s customizable with Cherry MX switches, so you can swap out the ones we provide with whatever special clicky switch you like. It’s a great example of consumer product manufacturing, showing you all the awesome things our software and our partners’ machines and services can do.

To bring this idea to life, we phoned our internal Fusion experts to lend us a hand.

This year you may have noticed the keypad looks slightly different. By playing around with form we were able to explore a world of possibilities.

To align our redesign project with the standards of professional Fusion users, we’ve integrated a change management process in accordance with ISO 9001 QMS. By utilizing the Fusion Manage Extension, we can effectively control, document and validate changes as we continually improve the aesthetics, functionality, manufacturability and assembly experience of this year’s Keypad 2.0.

With certain constraints in mind such as the screen positioning, dimensioning of the Adafruit Macropad, and cost to produce, we got to work designing in Fusion. During the process of designing this year’s Keypad 2.0 we examined the pain points users experienced when assembling last years product and worked to alleviate those concerns. This meant re-examining how parts fit together, and what the experience would be like for you all assembling this years product. The goal for the redesign was to make the keypad sleeker, more sustainable, and more enjoyable for you to assemble.

Check out the Autodesk Keypad V.2 in Fusion.

For this year’s factory event, sustainability and reducing our design’s carbon footprint were at the forefront of our minds. With our recent partnership with Gravity Climate bearing fruit in the form of a new add-in for Fusion called Manufacturing Sustainability Insights (MSI), the team saw it as the perfect opportunity to put our new in-product Life Cycle Assessment (LCA) tool to the test. MSI is a cradle-to-gate LCA tool integrated within Fusion’s design space. It was developed to provide users with live carbon impact feedback during the design phase of product development, allowing designers and engineers to understand the impact their design, materials, manufacturing processes, and location decisions have on the product’s carbon footprint.

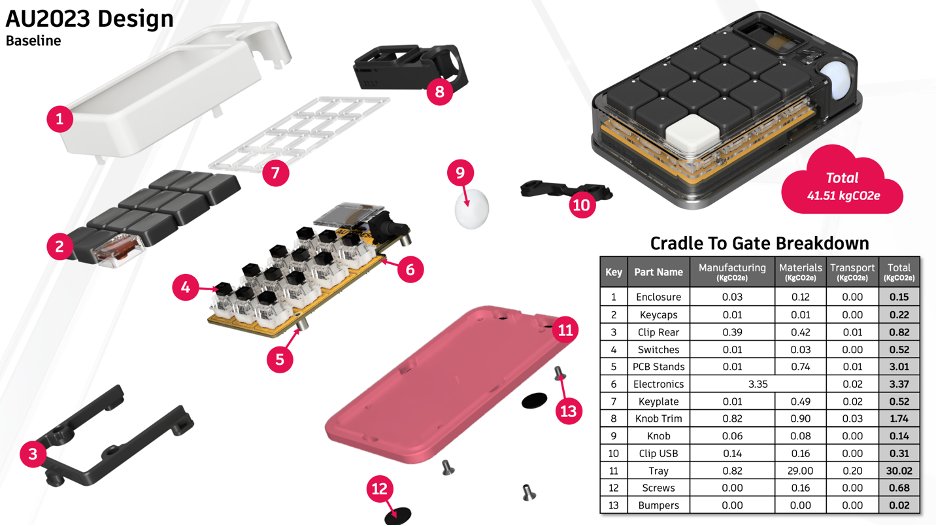

By using MSI, the team was able to baseline the previous year’s design, plugging in details of each component in the assembly to calculate the total carbon footprint of the product. The diagram below illustrates the manufacturing impact, material impact, and transportation impact involved in producing each of the AU2023 keypad components in their respective materials and manufacturing locations. Utilizing the MSI tool, the team could identify hotspots of carbon emissions and focus their redesign efforts on this year’s sustainable redesign.

As you can see in the baseline, the key areas for improvement were the aluminum tray, the enclosure, and the 3D-printed components. With the aim of minimizing the design’s impact while maintaining its functionality, durability, and showcasing the different manufacturing processes possible with Fusion, the team set out to redesign the keypad for this year’s event. Using MSI’s persistent view, a designer can have an always-on indicator that calculates the carbon footprint of a design based on your specified scope by simply highlighting. This feature makes it very easy to monitor the impact your changes have on the component footprint.

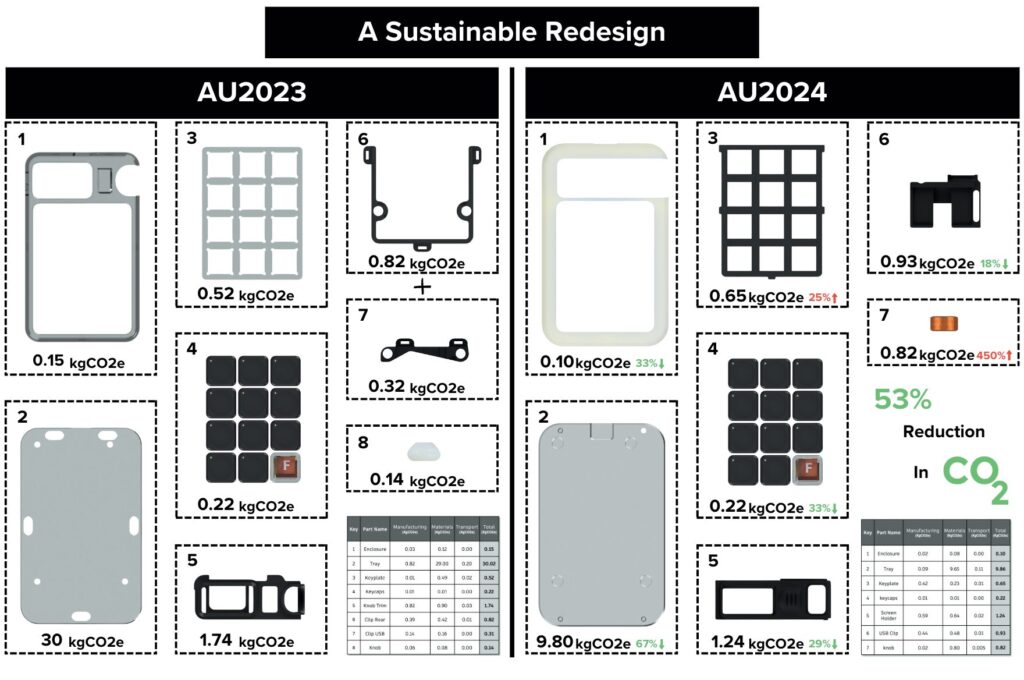

After many design iterations, the team finalized this year’s design. By using MSI, the team was able to almost halve the product’s footprint by designing parts that are more manufacturing and material efficient. The largest change was seen in the aluminum tray. By changing the components to a simpler design with fewer pockets and feature height variations, its footprint dropped by 20kg CO2e, primarily due to the ability to use a near-net stock billet instead of the larger volume needed for AU2023’s design. This design change, along with a more efficient design of the injection-molded enclosure and consolidating the additive components from three into two functional and aesthetic components, allowed for further reductions in the product’s carbon footprint.

A side by side comparison of the components for AU2023 and AU2024 can be seen the diagram above, if you would like to try out the MSI add-in for yourself, please follow the link here and download it off the Autodesk App store for free!

At last year’s AU Fusion Factory Experience, staying on top of every detail on the production floor was challenging! Using manual logs and spreadsheets only caused delays and was prone to errors. Especially when the team was assessing assembly bottlenecks! This year, we’ve implemented Fusion Operations to input the workflows for each manufacturing stage, from base materials to finished goods. Using live dashboards for real-time visibility and progress tracking keeps keypad production on schedule, running efficiently, while staying under budget. One of the key strengths of Fusion Operations is its ability to collect data such as cycle times and material waste, enabling you to analyze production performance and make informed decisions that drive continuous improvement across your entire manufacturing process.

We want to give a big shoutout and heartfelt thanks to our amazing partners for their incredible support in developing this year’s factory product. Your expertise and collaboration have made our vision a reality, and we couldn’t have done it without you. We’re so grateful for all your hard work and dedication, which have played a huge part in making this shaping this year’s factory experience. Thank you for being such an important part of our journey and helping us showcase innovation and excellence.

We are incredibly excited to share this innovative product with you in person at AU2024. Join us for a hands-on experience where you can assemble and customize your very own Autodesk Keypad V2.0. It’s a fantastic opportunity to see our design and manufacturing processes up close and take home a piece of cutting-edge technology. We can’t wait for you to experience the new and improved keypad, and we look forward to seeing you there!

By clicking subscribe, I agree to receive the Fusion newsletter and acknowledge the Autodesk Privacy Statement.

Success!

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.