This post is also available in: Italiano (イタリア語) Deutsch (ドイツ語) English (英語)

Autodesk Fusion 360 makes 3D printing easy by providing an integrated CAD/CAM environment, an additive manufacturing extension, helpful apps, and more.

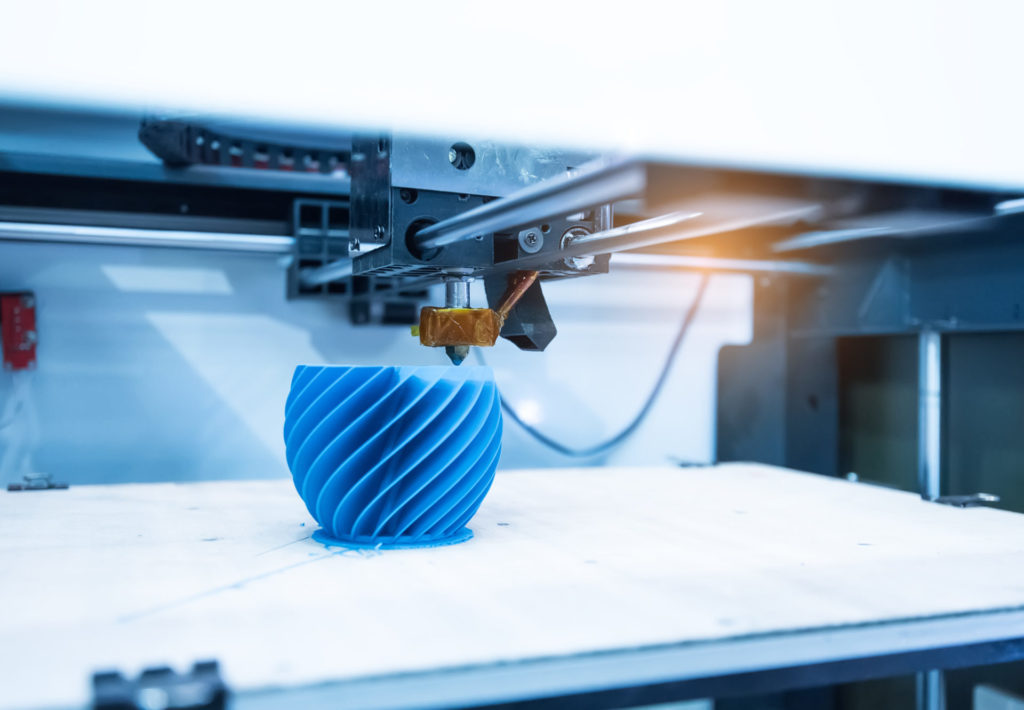

3D printing has, without a doubt, become one of the most common ways to design and create a project, whether it be a complex design or a simple hobbyist project. With the introduction of additive manufacturing technology comes the ability to realize unique projects that may not have been previously possible.

Gone are the days of drafting a 2D sketch and then manually creating a prototype or part. 3D computer-aided design (CAD) software bridges the gap between an idea and the final product. CAD software, such as Autodesk Fusion 360, brings several advantages to the drawing board to make the entire process easier and faster. The basic software platform includes tools to help even the least experienced designer on the team. However, there is also an advantage to supplementing the base package with extensions and additional applications.

What is Additive Manufacturing?

Additive manufacturing, also known as 3D printing, is an innovative method that allows for easy prototyping and accurate part production. Additive manufacturing processes can be categorized into three categories: melted solids, solidified liquids, or fusing powders. Refer to Understanding Additive Manufacturing Technology & Processes to learn more about additive manufacturing technologies.

So how does Fusion 360 make additive manufacturing and 3D printing projects easy?

3D Printing and Autodesk Fusion 360

Autodesk Fusion 360 unifies design, engineering, electronics, and manufacturing into a single integrated software platform. One helpful aspect of Fusion 360 is the 3D print preparation module. Using this tool, you can define your machine, orient the part, add a variety of supports, and create specific toolpaths to execute the design and 3D print. Now designers can avoid unnecessary printing preparation reworks that come with a design change.

Fusion 360 incorporates a variety of applications to enhance the basic features of the integrated CAD platform, such as:

Design for Additive Manufacturing:

Print Preparation for FFF:

- Additive Assistant (FFF)

- OctoPrint for Autodesk Fusion 360

- Ultimaker Digital Factory for Autodesk Fusion 360

- GPX PostProcessor for Autodesk Fusion 360

- Additive FFF Post Configurator

Print Preparation for SLS and MJF:

Print Preparation for MPBF and DED:

Outsourcing Additive Manufacturing:

All listed resources create a flexible and intuitive design space for even the most complex 3D printer design projects. What’s even better is Fusion 360 can connect to a library of 3D printers for more additive manufacturing benefits.

3D Printing Machines for Product Development

An integrated software environment is only as good as its compatibility with different hardware. Fusion 360 can connect with a variety of 3D printers, such as Ultimaker, EOS, and Renishaw. 3D printers are diverse in their manufacturing capabilities. Some use metal, and some use plastic polymers. Fusion 360 can manage it all with a comprehensive set of modeling tools to ensure form, fit, and functionality regardless of additive substances.

Designers shouldn’t have to buy a new 3D printer to use a new software package. With the help of Autodesk Fusion 360, they won’t have to. Check out Fusion 360 today to learn more about how to enhance your 3D printing processes.