Justin Baker always knew he wanted to work with his hands. He trained as an artist, learned aircraft maintenance serving in the US Air Force, then started a career operating animatronics that control the large, interactive puppets often used in live events, theater, TV, and film. He enjoyed working on crews responsible for blinking eyeballs and slithering tentacles.

Then a diagnosis of arthritis changed everything. “My arthritis was causing my hands and wrists to shut down,” he says. “But I still wanted to find a way to make things and help my friends in the arts. All I had to do was switch careers.”

Determined to take advantage of his personal experience with animatronics, Baker returned to school at Ivy Tech Community College in Indianapolis to enhance his mechanical engineering and machine tool technology skills. Not long after, he realized how to marry his former career with his new one.

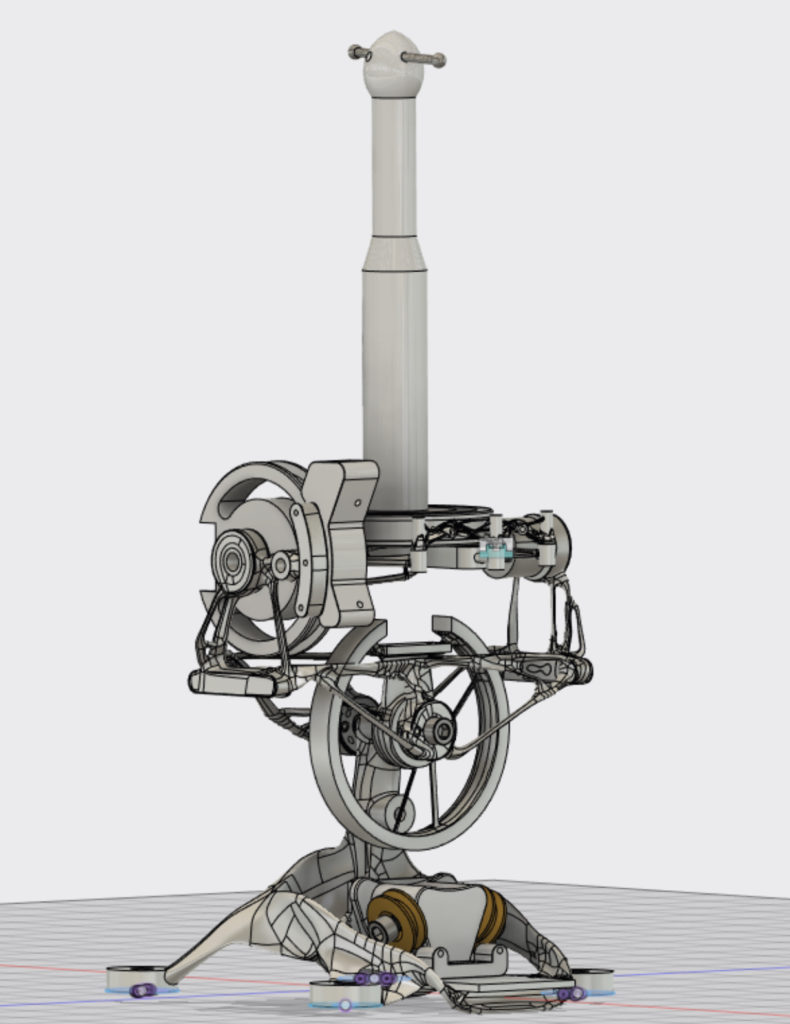

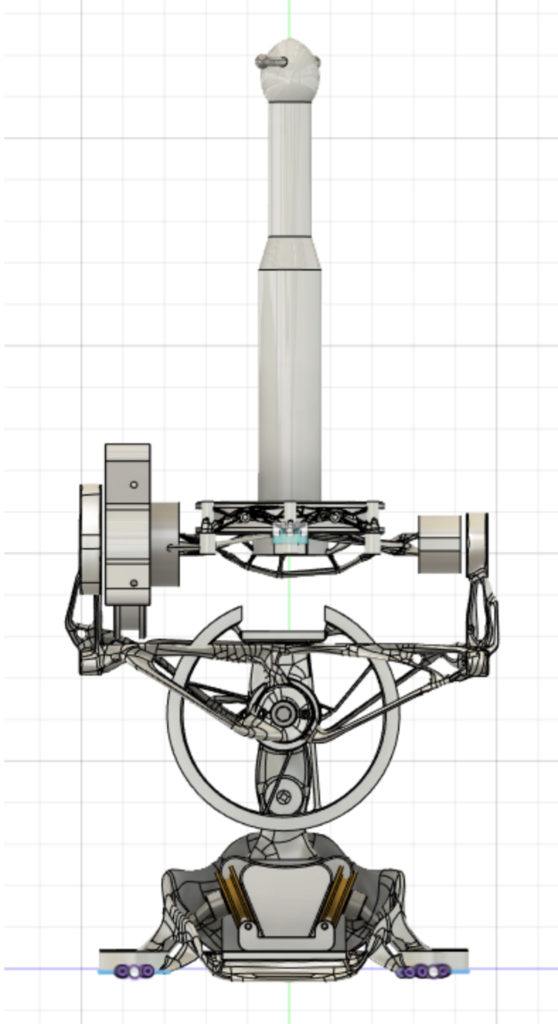

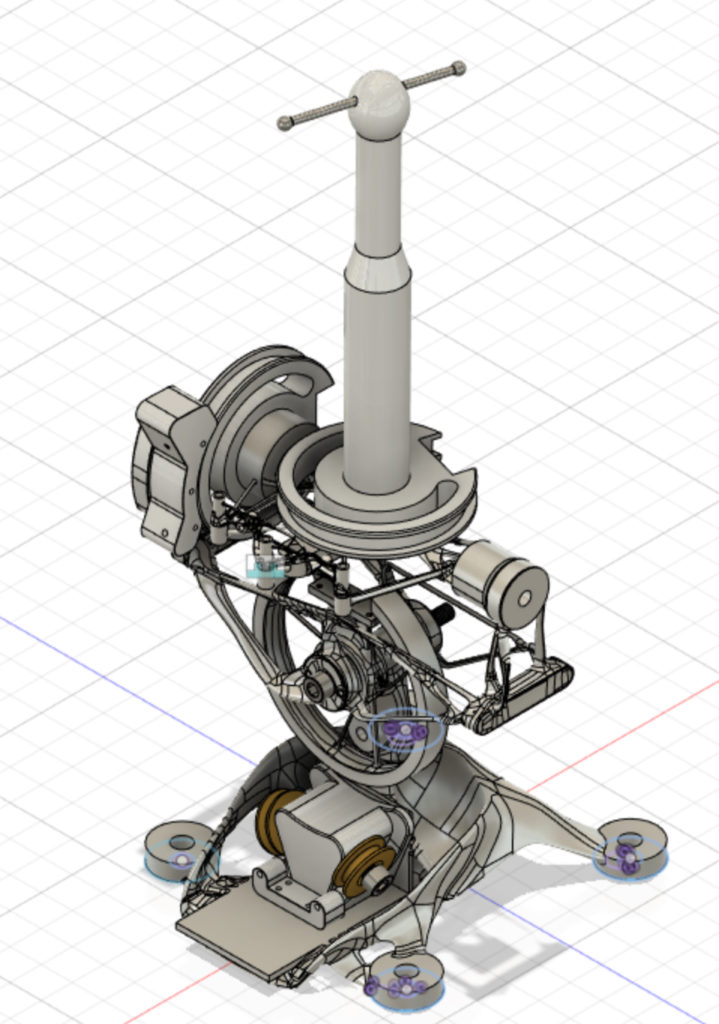

“The manual controls for puppets and animatronics are very heavy,” Baker says. “They weigh 30 or 40 pounds. The operator has to hold and manipulate the controller for hours at a time. Repetitive motion injuries are very common in the industry. I wanted to find a way to make these devices lighter so they have less impact on the operator’s body.”

Even though Baker is a student, he founded his own fabrication business to bring his ideas to life. One of the first tools he used to do this was Autodesk’s Fusion 360, particularly its generative design capabilities.

“My first controller was designed in Autodesk Inventor,” Baker says. “Then I took it into Fusion 360 and used generative design primarily for lightweighting. Most of these devices are designed in machine shops with no analysis of any kind. I wanted to remove as much weight as possible and knew generative design would help me accomplish that.”

Originally, Baker wanted to reduce the controller’s weight from 30 pounds to 10. But he ended up with a design that was 90% lighter than the original, with virtually the same strength characteristics. Additionally, Baker was able to consolidate down from 15 uniquely made parts to just five.

Overall, the design was suitable for additive manufacturing, but Baker wasn’t finished yet.

“The next step is making a version with a 2.5-axis constraint,” he says. “I want to make it easy to replicate in a small-scale maker space, not just my fabrication shop. I’m also developing a 2-axis version for laser cutting.”

Baker has only been using CAD for two years and Fusion 360 for about 18 months. Nevertheless, he found the software accessible and intuitive, so much so that his professors now describe him as a bit of a “generative design addict.”

“I really like the generative design suite,” he says. “If my professors give me an assignment to lightweight a design, I want to use it right away. Unfortunately, they have informed me I have to do all the work myself! It’s just so intuitive to use. People don’t realize how practical it is. Yes, you can make brackets with weird features, but you can also use it as one step in the design process.”

Baker remains focused on practical applications. The controller project’s success has inspired him to apply a similar approach to other equipment that TV and movie crews have to wrangle daily.

“I know some people who work on the crew of The Walking Dead,” Baker says. “They have me exploring projects for light stands, light brackets, and camera dollies, which are very heavy and have to be moved up and down stairs. There has to be something we can do about that.”