Learn about what manufacturing execution systems (MES) are, what problems they solve, and the benefits of implementation.

What is a Manufacturing Execution System (MES)?

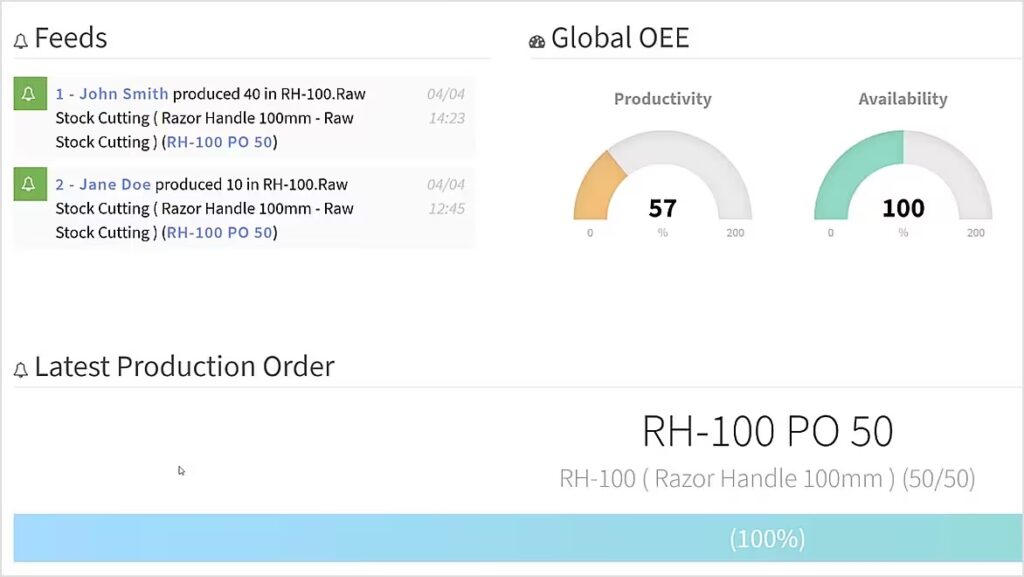

A Manufacturing Execution System (MES) is a software solution to automate and digitize manufacturing processes. Manage, monitor, and track the transformation of raw materials into finished products in real-time. Gain insight into manufacturing operations to see how to improve performance, lower costs and increase production efficiency.

MES ultimately enable you to extend your capabilities beyond product/process design release (PLM) and work order release (ERP) with a system that creates flawless manufacturing processes with one single source of truth.

What problems do Manufacturing Execution Systems solve?

Paper, email, whiteboard, and spreadsheet-based processes are no longer modern solutions to smart manufacturing. These systems inherit a high likelihood of human error and often lead to:

- High processing costs

- Increased waste and scrap

- Missed deadlines

- Low productivity

- Lack of critical information

In today’s competitive manufacturing environment, the demand for accurate and accessible data from the shop floor is a must. Some benefits of an MES system include:

What are the Benefits of MES?

- Digitalization and automation of paper-based processes – Gain access to real-time data such as labor, scrap, downtime, and maintenance with digital processes that scale across your entire supply chain.

- Integration with other systems – Seamlessly integrate your various systems to access more accurate data and improve decision-making.

- Reduction of raw materials and waste – Detect inconsistencies on the shop floor to quickly limit the number of bad parts and materials wasted.

- Elimination of production bottlenecks – Reduce delays and higher production costs by identifying blockers before hitting production.

- Reduction of costs – Get better insight into the time required to manufacture to free up production lines and reduce inventory.

- Reduction of inventory – More inventory equals more money. With access to up-to-date inventory records, always know what inventory is on hand and what you need to order.

This list certainly isn’t exhaustive. Other key benefits include improving product quality, reducing cycle times, empowering your employees, improving overall customer satisfaction, and much, much more.

Who uses MES?

An MES starts as a single source of truth with the shop floor at its core. However, all users across an organization benefit. From the quality control manager to the production manager, to the plant manager, and ultimately to the CFO and CEO, everyone benefits by having access to an accurate system of record at their fingertips.

Can MES and ERP work together?

Absolutely. While both tools have different capabilities, they can be easily integrated. ERP (Enterprise resource planning) tells you what decisions need to be made, while MES tells you how to make those decisions. The result? Two complimentary tools.

Want to learn more?

Are you ready to improve your facility’s efficiency with accurate data, production, material usage, and personnel time? Start a free Autodesk Fusion Operations trial to learn more.