Elevate your design and manufacturing processes with Autodesk Fusion

When the time came for MASS Design Group, an award-winning architecture firm, to propose their first project in the US, a pavilion for Boston’s Design Biennial, they knew they wanted to stay local. They recruited students, engineers and community organizations to help design and build what became the “Lo-Fab” (locally fabricated) Pavilion, a grid-shell structure that, unlike conventional installations, could be disassembled and rebuilt for enduring use.

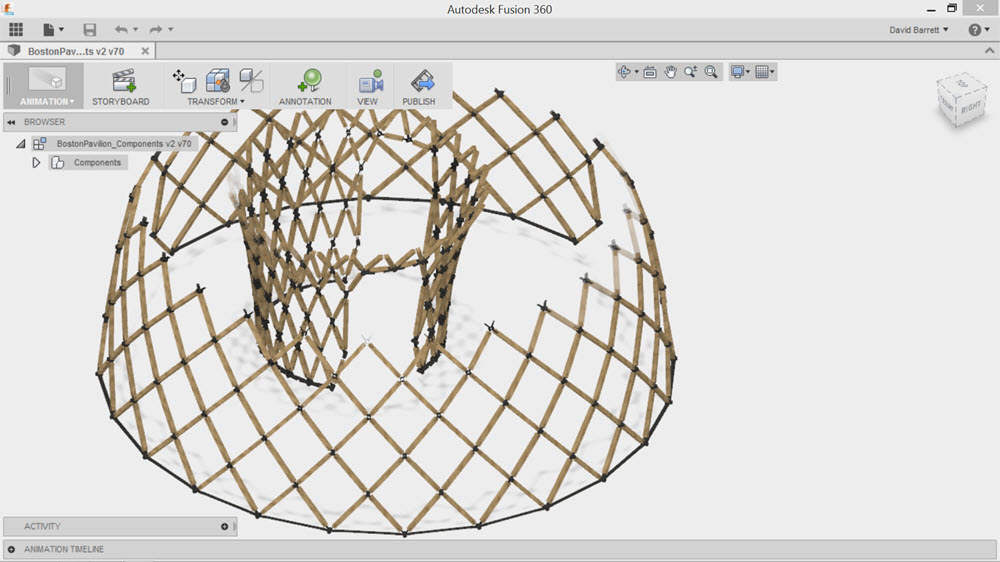

MASS Design and students from Virginia Tech’s Center for Design Research used Fusion 360 to not only collaboratively design tooling for the structure, but to simulate and animate how it should be assembled for volunteers on the ground.

Photo credit: Mark Pasnik

Photo credit: Cole Smith, Fusion 360 student expert

We caught up with Nathan King, who represents both MASS and the Virginia Tech teams to learn more about the project and how Autodesk helped contribute to its success.

Q: Why did you choose to participate in the Biennial challenge?

A: This project is a test-bed for MASS Design’s “Lo-Fab” (locally fabricated) approach to the design and building process. Lo-Fab is the “slow food movement” of fabrication and represents MASS Design’s commitment to understanding the people, processes and products that go into fabricated building components. This installation embodies our commitment to social equity and the use of local labor (students, engineers and community organizations) coupled with advanced fabrication techniques. Because it is composed of many small elements, this approach enabled the Boston community—including volunteers and students—to participate in the on-site assembly.

This is the first US project for MASS Design. We incorporated lessons learned from the “global south” into this project and, ideally, will take lessons learned and ideas tested on this project and apply them to our international work. The pavilion, a grid-shell structure made of a series of struts and nodes, offers a demonstration for a method of conserving materials by utilizing what would conventionally be considered “scrap” material.

Q: Will you take any lessons learned from this project back to your work in other countries?

A: Yes. The pavilion offers a demonstration for a method of conserving materials by utilizing what would conventionally be considered “scrap” material. MASS is also testing A360 Team as a long-term cloud platform to be used across all its projects, which will allow disparate teams to stay up-to-date on model edits. In addition, this project will be a first example of MASS Design

working collaboratively though the cloud using BIM, digital fabrication and associative modeling. This, combined with our emerging research on BIM for resource-limited settings, will help direct all future MASS work toward cloud-based collaboration.

Q: How are you working with Autodesk on this project?

A: Autodesk is the lead sponsor for the design and build of the MASS Design Biennial project. Autodesk provided grants of the software being used on the project, including Fusion 360 and Dynamo, among others. In addition, the MASS Design Biennial project is the first Autodesk BUILD Grant project selected for its innovative use of digital fabrication in the built environment.

The Autodesk BUILD Grant (for Building, Innovation, Learning and Design) program supports research by students, faculty, practitioners, and others advancing the state of practice in the building industry, particularly in the areas of digital fabrication, design robotics, material systems and automation in construction.

Beyond sponsorship the MASS and Virginia Tech teams have worked directly with software teams within Autodesk on the development of new software tools that were used in this project including contributions to the emerging Dynamo-to-Robot workflow developed in part, and tested in the Virginia Tech Center for Design Research Robotics Studio, with a team of collaborators from the Autodesk BUILD Space and Dynamo teams.

Q: Why did you choose to use Dynamo together with Fusion 360?

A: In addition to using Fusion 360 as a way to simulate kinematic movements, the promise of integrated CNC and robotic fabrication within its platform pushed us to explore Dynamo as a mechanism for creating the geometry of the structure. Our collaborators at the Center for Design Research at Virginia Tech have worked with the Autodesk developers on the new Dynamo-to-robot tool and this platform has a number of advantages over what is possible in the workflow. Ultimately the research seeks to make tools more accessible to more people since both Dynamo and Fusion 360 support this. Working on ways for the two platforms to communicate enhances our goals of democratized digital design and fabrication tooling.

Q: How was Fusion 360 used?

A: Integrating Fusion 360 allowed us to decrease time to fabrication and enhance collaboration via a cloud-based model. We capitalized on its cloud capabilities to collaborate remotely with the student experts from the Virginia Tech Industrial Design program on the development of the Fusion-related aspects of the project. We also leveraged cloud computing for the creation of visualizations and animations that allowed us to train volunteers in the assembly process before jumping into the construction site.

Photo credit: Cole Smith, Fusion 360 student expert

Q: What feature of Fusion 360 was most important?

A: Fusion 360 offered unprecedented access to compelling visualizations, animations, and other simulation tools that allowed us to test interference and collisions prior to assembly. Other tools that we’ve used in the past are not truly associative, so they don’t help in constructability analysis for a project of this complexity. The associate modeling relationships helped us understand construction sequence and identify issues.

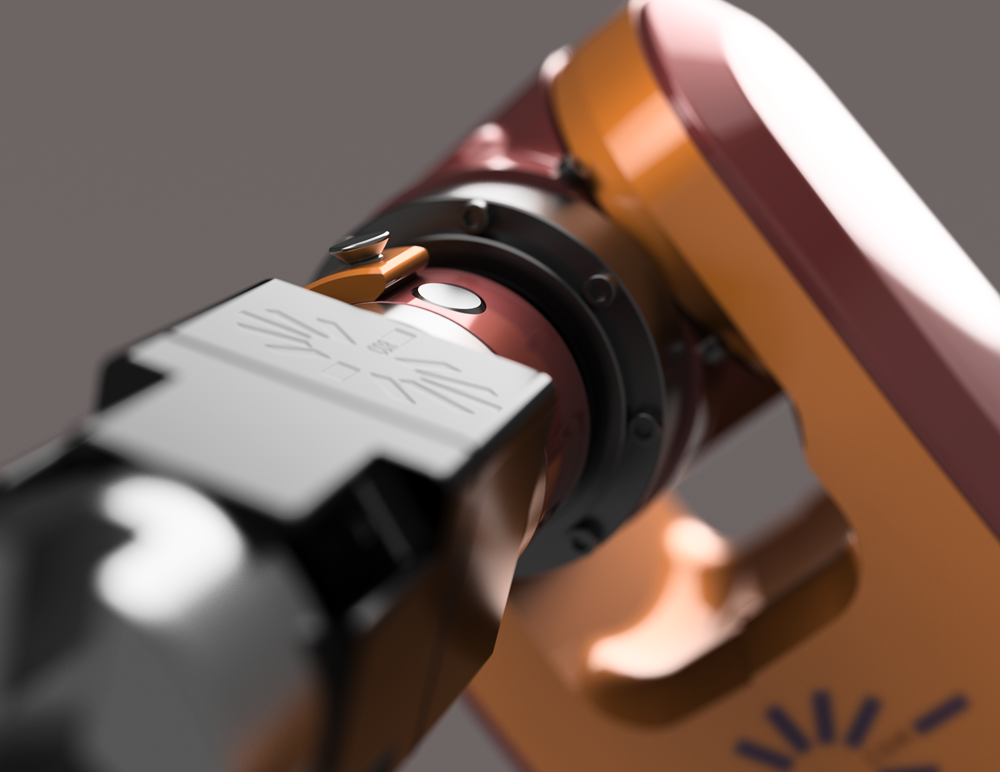

The second aspect of Fusion 360 that was equally important was the connection to HSM Works for the machining of tooling and custom parts. ALL tooling, fixtures, and jigs were designed in Fusion 360 and machined on a CNC Milling Machine using Fusion-to-HSM. This integrated workflow allowed us to create robotic tooling for the steel assembly and other fixtures very quickly without having to leave the single software environment! This was HUGE and will have a lasting impact on the way we use CNC tools that we are actively incorporating into our practice.

Q: How long did this project take to design and make?

A: The design of the project from initial student workshop and early conceptual ideas to fabrication took 12 weeks, but the bulk of the labor occurred in the last 4 weeks of the project where we went from model to component fabrication and ultimately assembly on site.

Image courtesy of David Barrett

Q: What are the implications of using this software for architects or builders?

A: Autodesk software is increasingly integrated. In a single design environment one can script, automate, visualize, and control manufacturing equipment. Competing software requires multiple platforms to do this. From a purely visualization standpoint, Fusion 360 rendering is unprecedented, simple, and it provides compelling stills and video within a single software solution. Furthermore, this does not bog down an in house system as renderings are produced in the cloud. Additionally, for low volume production of architectural elements- the provision of HSM and the link to manufacturing — also integrated into a single platform— is an incredible add and ultimately will reduce costs, enhance constructability analyses, and speed up the workflow.

Q: How would a project like this be done without Fusion 360?

A: This project is feasible without Fusion 360 but what it afforded us was the ability to bypass several other software platforms. This project started in that way and typically would have been executed in multiple steps using many software platforms. One for design, one for visualization, one for CNC coding, etc. For the parts of the project that used Fusion, all three aspects were streamlined especially in the development of the tooling used to robotically fabricate the pavilion.

Q: How has MASS Design partnered with Virginia Tech Center for Design Research?

A: Students and faculty at Virginia Tech, in direct collaboration with designers at MASS Design Group, developed the structure as part of an ongoing founding partnership in the Commonwealth Consortium for Design and Health — a collaboration that allows multiple universities, design practices, and industry partners to collaborate in the development of innovative design technologies, evaluation methods, and medical devices for use in resource limited settings. This collaboration resulted in the technology transfer of an advanced façade systems developed for the centers’ LumenHAUSTM into application in the recently completed Cholera Treatment Center in Port-au-Prince, Haiti by MASS Design Group.

The MASS Lo-Fab Pavilion at the Design Boston Biennial represents the second such opportunity to explore the translation of advanced design and fabrication techniques to the design and construction process in resource limited settings.

The pavilion speaks to MASS Design Group’s approach to the design and building process.

“On every project, we highlight and scale local innovation and ideas, hire local labor, and use local materials. This kind of architecture is making human lives better, and this is how we evaluate design integrity and the success of our projects. From our ethos, we draw a core set of principles that ensures we deliver sustainable and beautiful buildings, but also that we spread this ethos by training a growing generation of designers and architects,“ said MASS Co-founder Michael Murphy when describing the project.

In the spring of 2015 a series of design charrettes were held between MASS, the Center for Design Research, students from Virginia Tech’s architecture and industrial design programs, and the computational design consultants The United Nathans. These engagements resulted in the development of an experimental gridshell structure that is fabricated using state-of-the art collaborative robotic fabrication techniques and a merger of traditional craftsmanship and computationally driven manufacturing processes. In order to move from the computational design environment to one of material, the team worked in collaboration with Autodesk to develop a novel design-to-robotic fabrication workflow using the emerging visual scripting interface Dynamo.

Over the course of five weeks students from the School of Architecture + Design produced building components at the College of Architecture and Urban Studies’ Research and Demonstration Facility in Blacksburg. Students and faculty travelled to Boston to erect the pavilion on the greenway, working long hours hand in hand with designers from MASS Design and Rudabega to deploy the experimental structure. The construction, a performance in and of itself, is intended to reconnect the process of making with the value afforded by a considerate merger of labor, material, and technology, and thus reestablishing the connection between the built environment, its users, and those who make it.

Beyond the artifact, this project is about process…one that enables students, practitioners, industry specialists, and community members to come together and teach each other through making…the act of making, at this scale and complexity, requires collaboration — this is why it is valuable, why we work in this manner, and how the learning of a single project will propagate.