Mechanical engineering demands precision, optimization, and real-world performance insights. Autodesk Fusion offers powerful simulation tools to validate and optimize your designs. For advanced capabilities, the Autodesk Fusion Simulation Extension is your ultimate resource, enhancing your ability to simulate, refine, and perfect designs with even greater accuracy and efficiency.

The power of Autodesk Fusion’s simulation tools

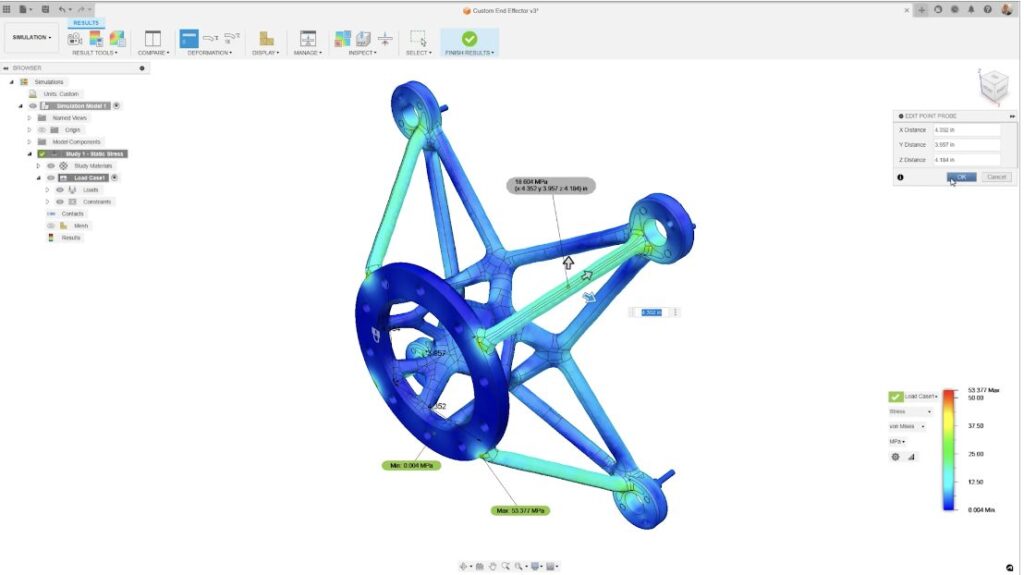

Autodesk Fusion comes equipped with a robust set of built-in simulation tools, offering essential capabilities for mechanical engineers. These tools analyze structural stresses and thermal performance to ensure your designs meet safety and functionality standards.

- Structural Analysis: Conduct linear static analysis to determine deformation, stress, and strain under static loads. This ensures that your designs can handle the forces they’ll face without permanent deformation.

- Thermal Analysis: Use steady-state and transient thermal analysis to evaluate temperature distribution within your design, helping you prevent overheating and ensure components operate within safe temperature ranges.

- Vibration Analysis: Predict how your design will respond to various vibrational frequencies, helping you identify potential resonance issues and ensure smooth operation.

While these built-in tools are incredibly useful, the Autodesk Fusion Simulation Extension takes your capabilities even further, offering advanced functionalities that provide deeper insights and more refined results.

Why you need the Autodesk Fusion Simulation Extension

The Simulation Extension is designed to empower your team with advanced tools that go beyond basic simulations. Here’s how it enhances your design process:

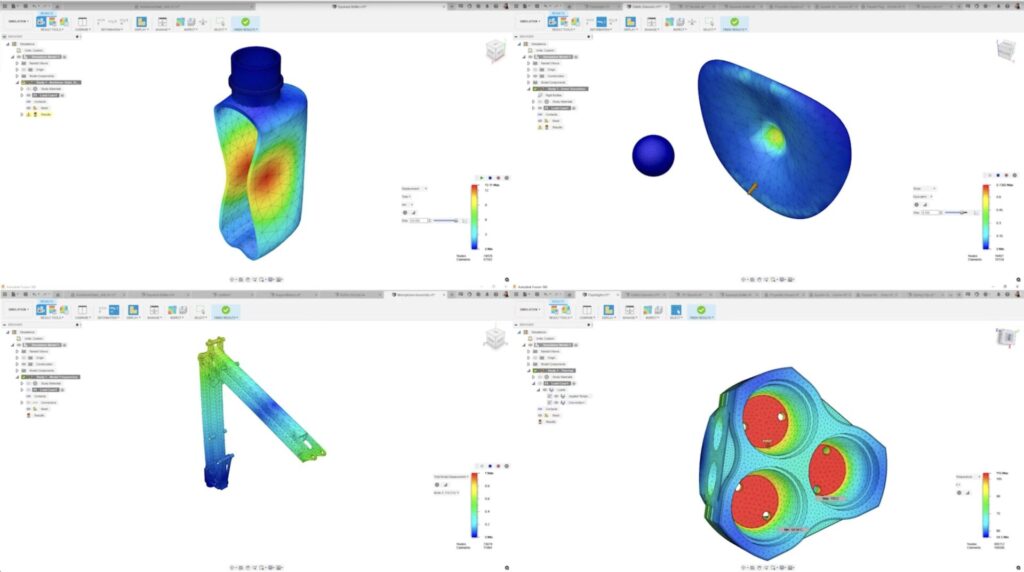

- Nonlinear Static Stress: Simulate complex material behaviors, large deformations, and load changes, ensuring that even the most intricate designs can withstand real-world conditions.

- Structural Buckling: Refine your designs to prevent structural failure by understanding critical buckling points, which is vital for ensuring the safety and reliability of slender structures.

- Event Simulation: Predict how your design will perform under time-dependent forces, which is crucial for applications where your designs are subjected to dynamic loads over time.

- Generative Design: Explore multiple design outcomes that meet your specifications while reducing weight and enhancing performance. This AI-driven tool opens up new possibilities, helping you create optimized designs that are both innovative and practical.

- Injection Molding: Analyze how your part design will influence manufacturability and quality in plastic injection molding processes, ensuring that your designs are production-ready and meet quality standards.

Unlock the full potential of your designs

The Fusion Simulation Extension goes beyond enhancing existing tools by integrating AI-driven insights and process-aware simulations, expanding your design possibilities. Whether managing complex materials, heat in electronics, or refining designs for manufacturing, this extension provides the tools for success.

By investing in the Autodesk Fusion Simulation Extension, you’re not just getting software—you’re advancing your design process. It shortens development time, reduces physical prototypes, and enables data-driven decisions for a more innovative and reliable final product.

Optimize your design process, improve performance, and ensure manufacturability—all with the Autodesk Fusion Simulation Extension.