Fusion 360 is proud to sponsor Chomp, the 250-pound wrecking machine entering the ring on the fighting robot show BattleBots, starting on June 21st at 9pm EST on ABC. She’s designed to chomp her opponents with 30 tons of force, and if that weren’t enough, she also breathes fire! Read on to learn about what it took to create this awesome robot.

How do you turn a robot designed for destruction into a twisted pile of metal? By creating your own equally menacing war machine! That is exactly what the The Machine Corps set out to do when they created Chomp the 250-pound robot that will be competing to be the BattleBots champion this June on ABC.

So how does one even begin to create a BattleBot? Like so many designs it begins with an idea, a sketch on a napkin and some pretty slick artwork. But turning those doodles into a reality is where the challenge begins, and the 5-person Machine Corps (Zoe Stephenson, Jascha Little, Jo Balme, Travis Smith, and Scott Little) had just 3 months to do 100% of the brainstorming, design, fabrication and testing for this machine. They turned to Autodesk Inventor and Fusion 360 to start the process.

The concept art, from late February 2015.

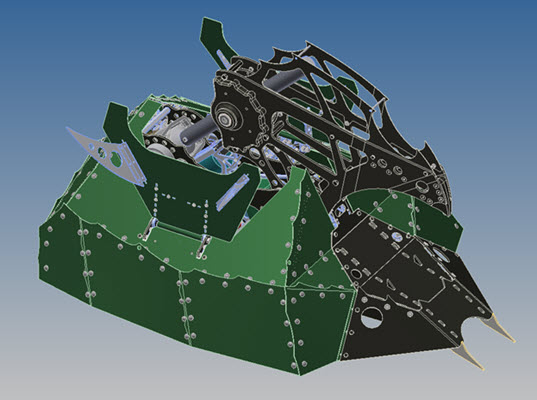

The final design, from May 2015.

To create such a design in a short period of time and with limited funding, making sure everything is designed accurately and efficiently is crucial. “Thank goodness for Autodesk’s sheet metal design suite, and for iFeatures!” says Zoe Stephenson, lead engineer. “I learned a lot about the versatility of those sets of functions in designing and manufacturing Chomp. They’re both incredibly powerful sets of tools.”

All of the custom design work for the chassis, to the titanium armor and even Chomp’s menacing giant fang were created 100% in Autodesk products and machined 100% with Fusion 360’s efficient CAM tools. Using the CAM available inside of Fusion 360 the team was able to accurately mill their complex, high accuracy parts in time for the battle! Here’s just one example: Chomp’s fang in programming and the finished product:

“I’ve used a lot of different pieces of CAM software in my engineering and fabrication career,” says engineer Jascha Little, who did most of Chomp’s CNC machining. “Fusion 360’s tools are by far the most intuitive.”

In total the design, manufacturing, assembly and testing took hundreds of hours and cost nearly $20,000! What we’ve shown you here doesn’t nearly do justice to the intricate assembly, vast number of parts (about 370 unique parts and 3000 total parts) and power of Chomp. However, we have good news!

As proud sponsors of Chomp (and The Machine Corps) we are running a contest to make her CAD design available to you in Fusion 360 just by following her on Twitter (@AlwaysBChomping) and Facebook! With this you’ll be able to explore how Chomp was designed, understand what parts goes into making a nearly unstoppable bot and even modify her design to come up with your own BattleBot! Here’s how it works:

1. Follow Chomp on Twitter (@AlwaysBChomping) and Facebook (https://www.facebook.com/ChompTheBattleBot)

2. When Chomp reaches 1,000 combined Twitter followers and Facebook Likes, the armor model will be unlocked.

3. At 2,500 the wheel module becomes available.

4. At 5,000 Twitter followers + Facebook Likes, the entire BattleBot design will be available for downloading on the Fusion 360 Gallery!

So what are you waiting for?!? Get out there and start supporting your new favorite robot! Make sure to tune in to BattleBots on ABC at 9pm EST starting June 21st for your chance to see Chomp in action, as well as the other great participants in this year’s battle. We’re looking forward to making her model available for everyone to download and want to see what kind of bots you come up with, so let’s make it happen! And remember, Always Be Chomping!