Learn about the progress we’ve made with our ModuleWorks partnership, including three new machining strategies you can preview today: Rotary Pocket, Rotary Contour, and Deburr.

Earlier this year, we announced an agreement between Autodesk and ModuleWorks to bring even more advanced manufacturing capabilities to Fusion 360. Since we made the initial agreement, the Autodesk and ModuleWorks development teams have worked closely to identify the most valuable capabilities to add to Fusion 360. A great deal of attention has gone into the overall user experience. All of the new features look and feel just like any others that are already in Fusion 360, making it extremely easy for new and existing users.

In this article, we’ll share more information about the first wave of new ModuleWorks capabilities available in Fusion 360, which we just released as preview features in our recent product update.

Now available to preview

As announced in our recent product update, you can now preview the following three strategies:

- Rotary Pocket (also known as 4-axis roughing)

- Rotary Contour (also known as 4-axis finishing)

- Deburr (supporting 3-, 4- and 5-axis machining)

These three strategies are initially available for Fusion 360 customers to use via “Extension Preview.” This provides an opportunity for users to experiment with the new functionality to see if it’s right for their needs, as well as provide feedback to Autodesk. Following the preview period, the new ModuleWorks capabilities will be released to customers with a subscription to the Fusion 360 Machining Extension.

Let’s take a more detailed look at this first wave of new strategies that you can currently preview.

Rotary Pocket and Rotary Contour

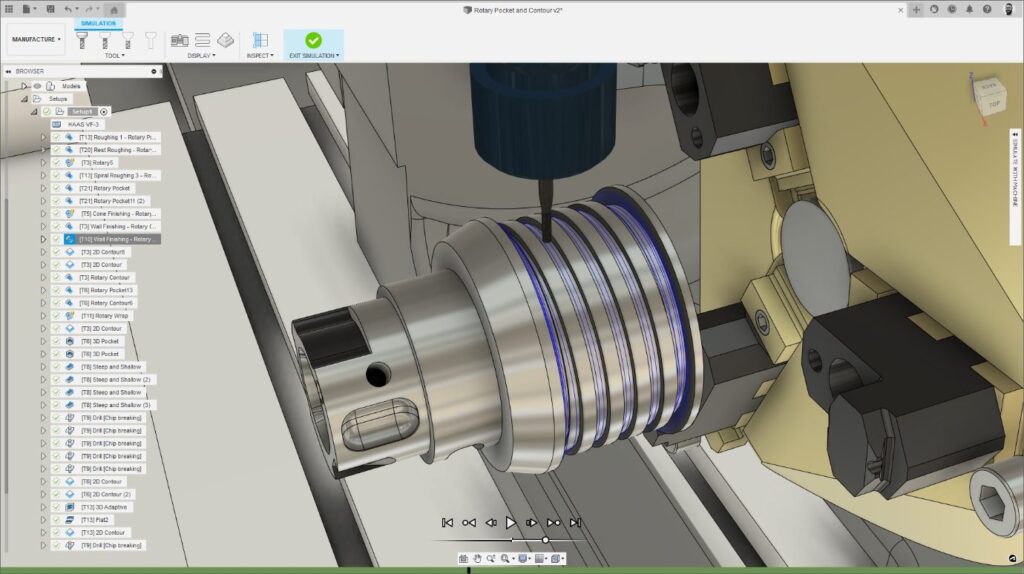

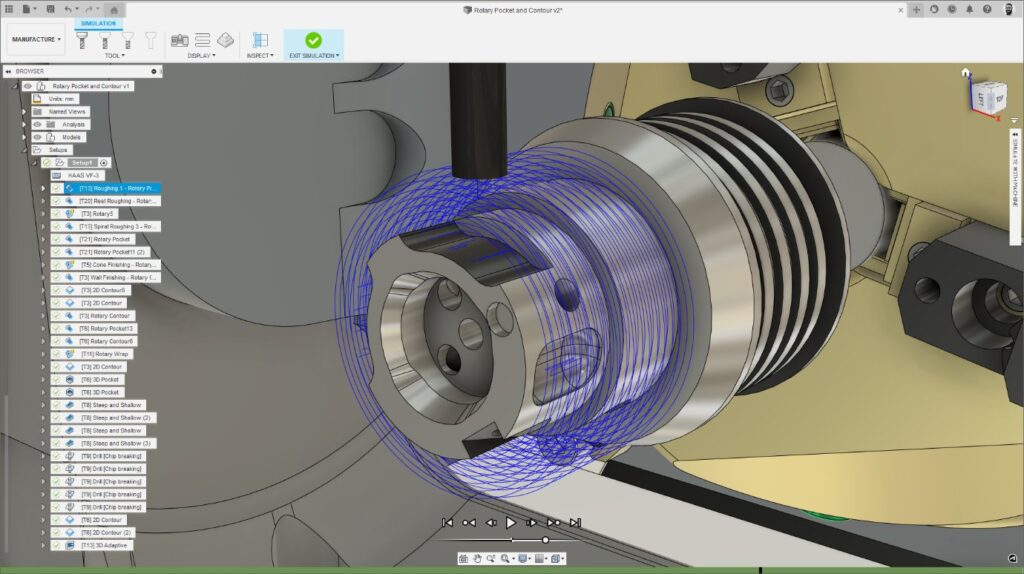

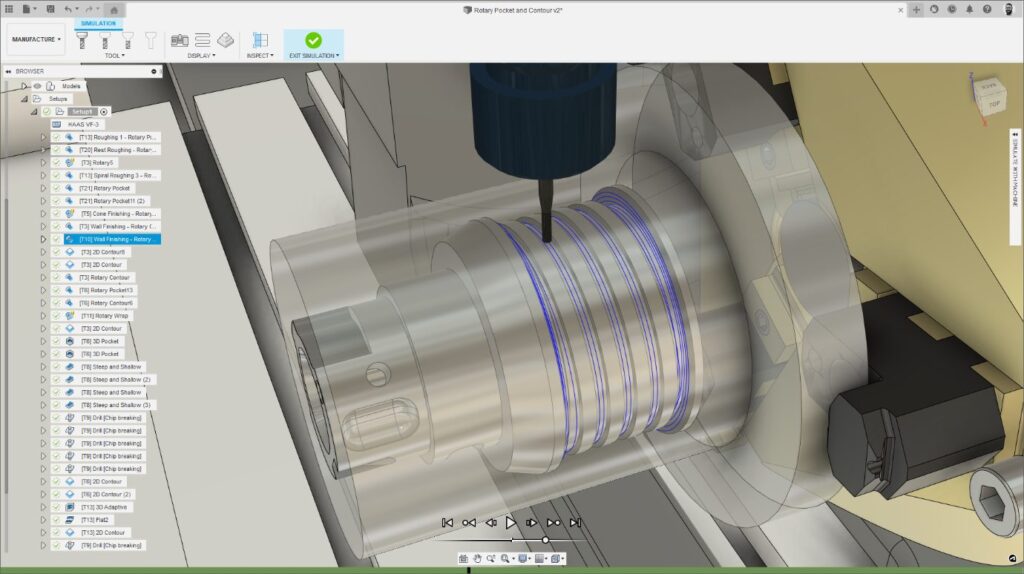

Kicking off with two new 4-axis machining strategies; Rotary Pocket (also known as “4-axis roughing”) and Rotary Contour (also known as “4-axis wall finishing”).

Rotary Pocket is ideal for those wanting to use simultaneous 4-axis machining to remove large amounts of material from parts efficiently. This is ideally suited to the machining of cylindrical or conical shapes but is not limited to these kinds of components, meaning it can also be used on free-form geometry. The strategy supports ball nose, end mill, and tip radiused cutting tool types.

Rotary Contour complements Rotary Pocket by efficiently machining the sidewalls of pocket features, also using simultaneous 4-axis machining. It is best suited to parts that contain pockets or nested features with sidewalls that radiate from the central axis of the part.

Rotary Pocket and Rotary Contour advanced options

Rotary Pocket and Rotary Contour include the following advanced options for additional control over the style and extent of machining, including:

- Machining limits that can be controlled using inner and outer diameters, front and back machining planes, or user-defined boundaries – most of which can be selected off the model or entered numerically. This helps you precisely control where machining does (and does not) occur.

- Rest machining that can be used to further limit machining to only remove the stock left on by previous operations.

- Toolpath ordering options that control whether parts will be machined by depth or by pocket, with the latter option generally creating toolpaths with fewer tool retractions, resulting in faster cycle times.

- Toolpath offsets that can be derived from the shape of the underlying part being machined. Alternatively, Fusion 360 can recognize open regions of the part that can be machined more effectively with simple spiral passes, reducing overall machining cycle times.

- Tool offsets that can be used to optimize cutting conditions by controlling whether the machining happens on the leading edge of the tool, the non-cutting center point, or a user-defined distance between the two.

- Automatic shaft and holder clearance that identifies and removes any toolpath sections where the tool assembly could collide with the target CAD model.

Benefits and highlights:

- Highly efficient means of machining 4-axis parts

- Can machine complex geometry that cannot be programmed with a simple “wrap” toolpath

- Multiple advanced options help optimize cutting conditions to prolong tool life and minimize overall machining cycle time

Deburr

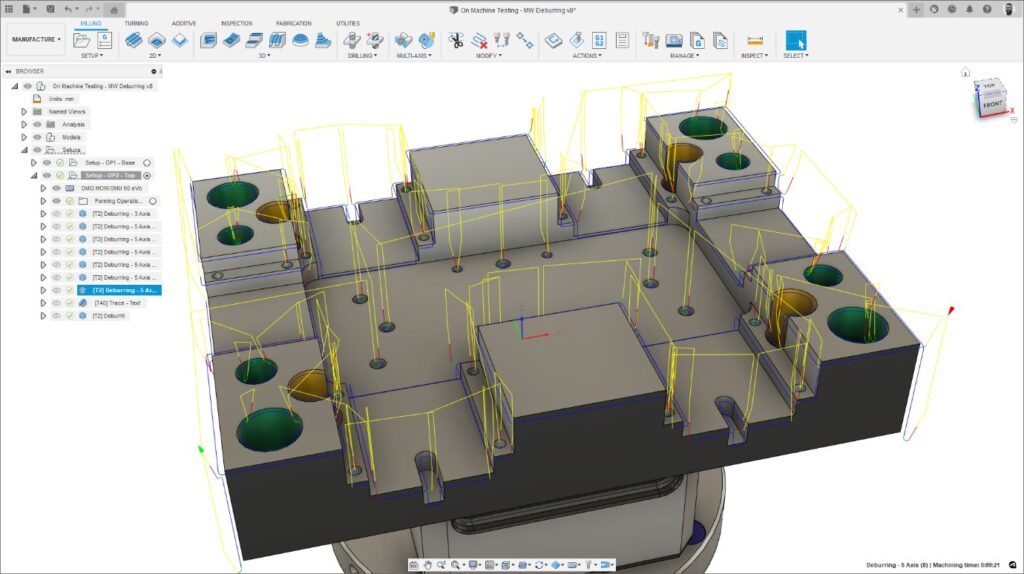

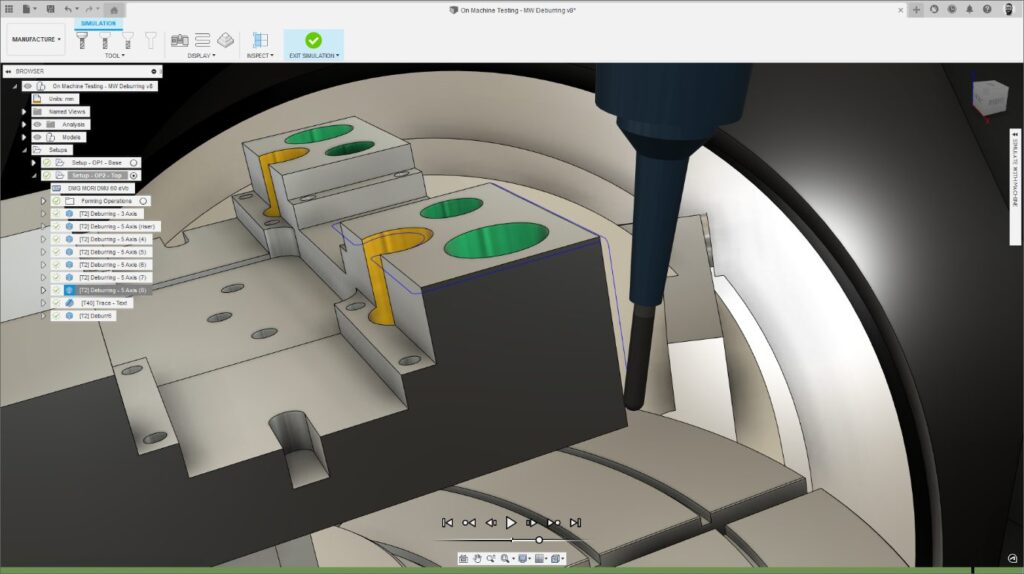

The third new strategy available to preview is Deburr. As the name suggests, you can use this intelligent toolpath to remove the small burrs that are often left on the edges of parts after CNC machining. Without this strategy, you would typically need to remove these burrs by hand, a process that can be both time-consuming and poorly controlled.

Deburr works by identifying sharp edges on parts and then producing toolpaths that intentionally remove a small amount of material from the edge using 3-, 4-, or 5-axis machine motions. When using multi-axis machining, you can use a range of options to precisely control the machine motion and tool orientation while adhering to the subtle limitations of the specific machine type.

Deburr capabilities

Deburr includes the following advanced options:

- Edge selection and exclusion options allow you to control which edges need to be machined and which ones should be ignored.

- Minimum edge angle allows you to control the extent of machining (a greater angular value will result in edges being ignored).

- Include rounded edges causes Fusion 360 to include any small radii that may have been added to the CAD (this is in addition to sharp edges).

- Tool orientation can either be derived from the underlying CAD model geometry or aligned to a user-defined vector.

- Avoid surfaces can be selected and used to limit the extent of machining (for example, to prevent the tool from touching clamps).

- Clearance heights can be used to define a safe area that the cutting tool will withdraw to between cuts. The safe area can be defined using automatic, planar, cylindrical, or spherical options with additional settings to control the size, orientation, and position of the area.

- Edge type allows you to choose whether to remove a burr or form a small, rounded corner on the edge (to a user-defined size).

- Unreachable corners force Fusion 360 to lift the cutting tool away from the geometry being machined. This allows the very tip of the tool to be used to access internal corners and other, more challenging features. This includes additional “corner loops” to smooth out machine motion.

The strategy supports many different types of cutting tools – including end mills, tapered, conical, or chamfer tools. However, the strategy works particularly well when combined with ball nose or lollipop cutters – especially if wishing to use 5-axis machining.

Benefits and highlights:

- Removes the reliance on hand-deburring

- Choose whether to deburr or form a rounded fillet

- Plugs a gap in Fusion 360, removing the need for complex programming workarounds involving strategies like “Trace”

What’s coming next?

Stay tuned — there are plenty more features from our ModuleWorks partnership to come! We’ll be sharing more details about the next features in the coming weeks, including:

- Advanced Swarf

- Geodesic Machining

- Automatic 3+2 Roughing

- Simultaneous 5-axis Roughing

- Simultaneous 5-axis Pocket Finishing (with support for barrel cutters)

How to activate preview features in Fusion 360

Excited to try Rotary Pocket, Rotary Contour, and Deburr? Activating Fusion 360 preview features is easy. Follow the steps outlined on this page, and you’ll be able to access these three preview features and more.

In the meantime, download Fusion 360 today to explore our extensive CAM offerings: