This post is also available in: Français (French) Italiano (Italian) Deutsch (German) 日本語 (Japanese)

See how Moose Toys uses Fusion to prototype, design, and make the highly successful Magic Mixies toy line.

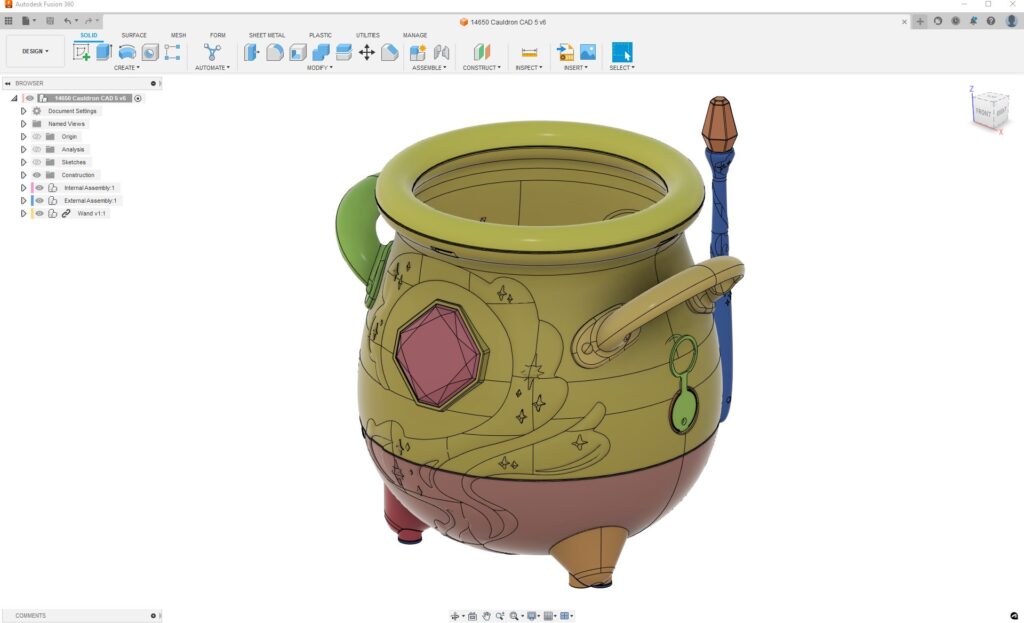

Moose Toys’ Magic Mixies isn’t just a toy. It’s an entire experience where kids channel their inner sorcerer. With waves of a glowing wand and a dash of magic potion, they can cast spells to conjure a fortune-telling pet from a cauldron or crystal ball. Real mist billows as a new plush animal emerges with surprise and delight.

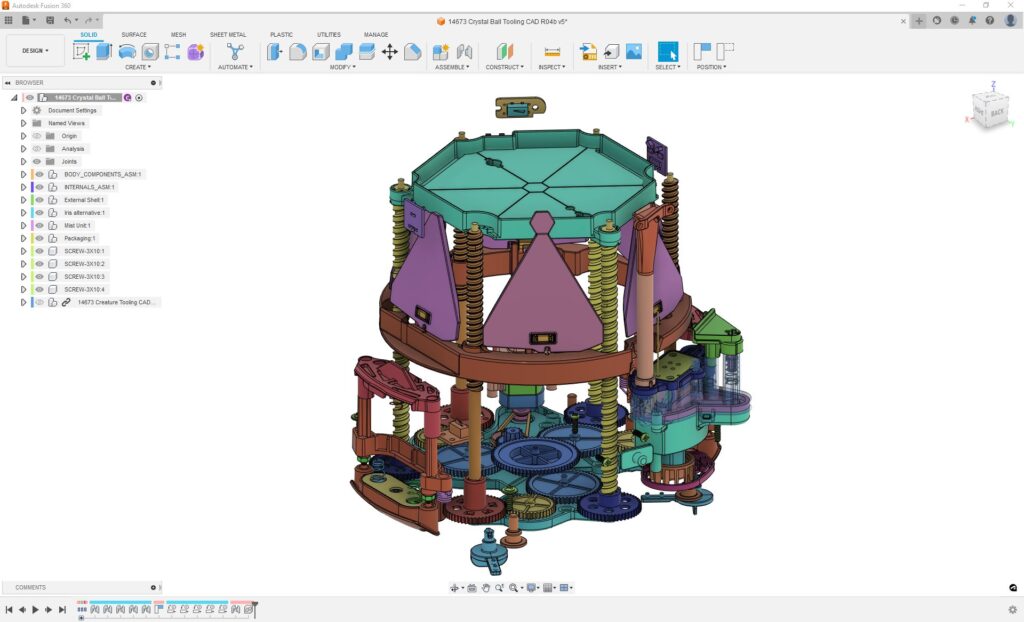

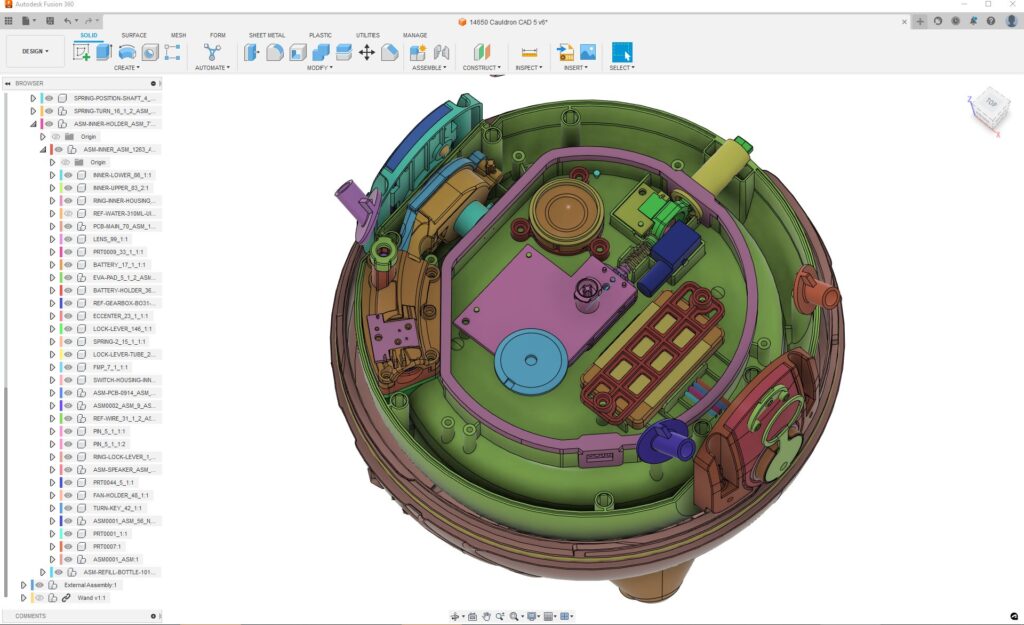

This award-winning, best-selling toy didn’t happen by magic, though. The wizardry behind Magic Mixies was an extraordinary design and manufacturing process powered by Autodesk Fusion — even down to the mist that emanates like fog to create a mystical moment. “We went for a lot of development on that mist, and it’s something that hasn’t ever been done before,” says Carl Budd, engineering manager, Moose Toys.

Quick turnaround without sacrificing quality

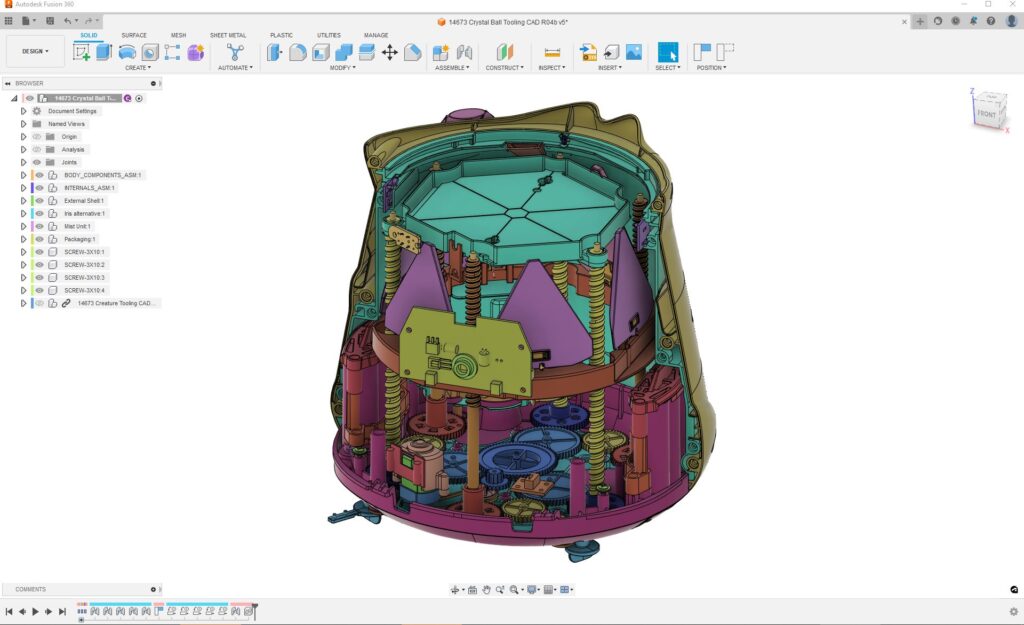

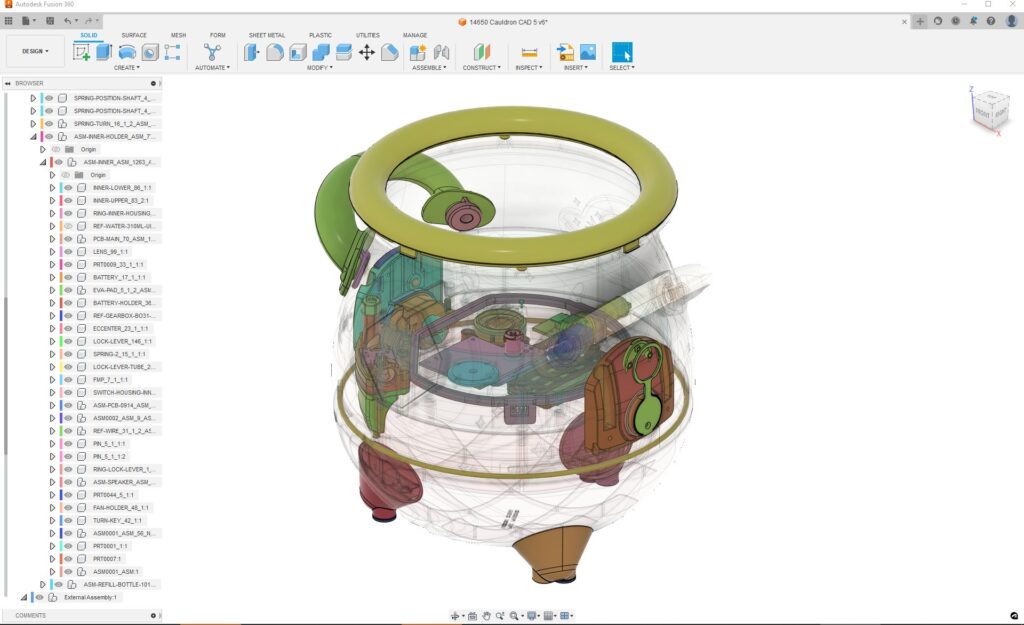

But the mist was just one component of an incredibly complex — and fast — development cycle for the intricate product. The team used Fusion to take the entire concept to a working prototype within 3-4 months. Design and manufacturing for the first Magic Mixies was completed and available in just 18 months — even during the height of the pandemic.

“It was probably the highest complexity for a project that we ever ran entirely remotely,” Budd says. “We did all the design reviews and collaboration remotely with our global teams. It certainly gave us the opportunity to do something better rather than a siloed approach if we had still been using SolidWorks.”

The electronics alone are impressive with Magic Mixies. But you rarely see a plush toy combined with hardware. This made for another design and engineering challenge. “Soft goods are an extremely difficult thing to try and model in CAD software,” Budd says. “With Fusion, we could get a plush look for our early internal renderings. For the Mixies Crystal Ball, we worked it out by using the form tool and applying decals and things to the surface of the form.”

Based in Melbourne, Australia, with offices worldwide, Moose Toys is a family-owned and operated business founded more than 30 years ago. It now has more than 600 employees with annual global sales exceeding $1 billion and a distribution network in 100 countries. It’s known for many popular toys and brands, from Shopkins to Little Live Pets, Goo Jit Zu, Akedo, and a new line this past year based on the popular Australian animated series “Bluey.” Above all, the company’s core mission is to make children “Superhappy,” as they put it.

Behind the scenes: Prototyping a toy design

It isn’t all fun and games in the toy business, though. Competition is stiff. Speed to market is critical to get ahead of trends and fickle consumer demands. Copycat products are always lurking around the corner. An efficient design and manufacturing process is key to transforming new ideas into products kids will love — and making it all happen quickly.

“It’s a fast industry,” Budd says. “Things that are hot one year are completely old news the following year. We have to be very, very agile. Every year is different, and we’re always working on different products and improving what we already have on the market.”

Fusion is now Moose Toys’ core platform for design and manufacturing. Most of the company’s design work and prototyping for mechanical items is done in Melbourne in conjunction with work in their Los Angeles and UK offices. The team’s typical design process starts with very high-level concepts from the creative team. The Moose Toys engineering team will get involved early to ensure the idea is achievable with materials and price points. Of course, the marketplace is a huge consideration for desirability and demand from kids, parents, and distributors alike.

Once the initial design reviews are completed and vetted, a product designer will provide sketches, and Budd and his team will go to work on prototyping in Fusion. Prototyping is a multi-layered process for proof-of-concept of both mechanical and electronic functions.

“We’ll sit down and work out all the mechanisms,” Budd says. “We design all the internals in-house with Fusion. We have a workshop with a nice raft of tools, an electronics lab, and 3D printers.”

Hands-on product testing

With a prototype in hand and functionality in place, the team will present it to senior leadership for feedback. But the real litmus test? It’s the kids.

“We have a lot of kids come into the office to do hands-on product testing for us,” Budd says. “It’s good to get that feedback as well. It doesn’t seem to matter how carefully you sit down and think about how a kid might interact with something you’ve designed. They will always find a new way to use it.”

From there, the team will resolve any design changes, perform the final check for safety and compliance, and finish the prototype design before passing it over to the teams in Hong Kong and China for production. This involves quite a bit of material optimization, part counts, and bill of materials calculations to ensure the best possible price for going to market.

“Collaboration in Fusion is a massive advantage, especially given that we’re a global company,” Budd says. “We can share our files between all our offices in Australia, Hong Kong, the UK, the U.S., and more.”

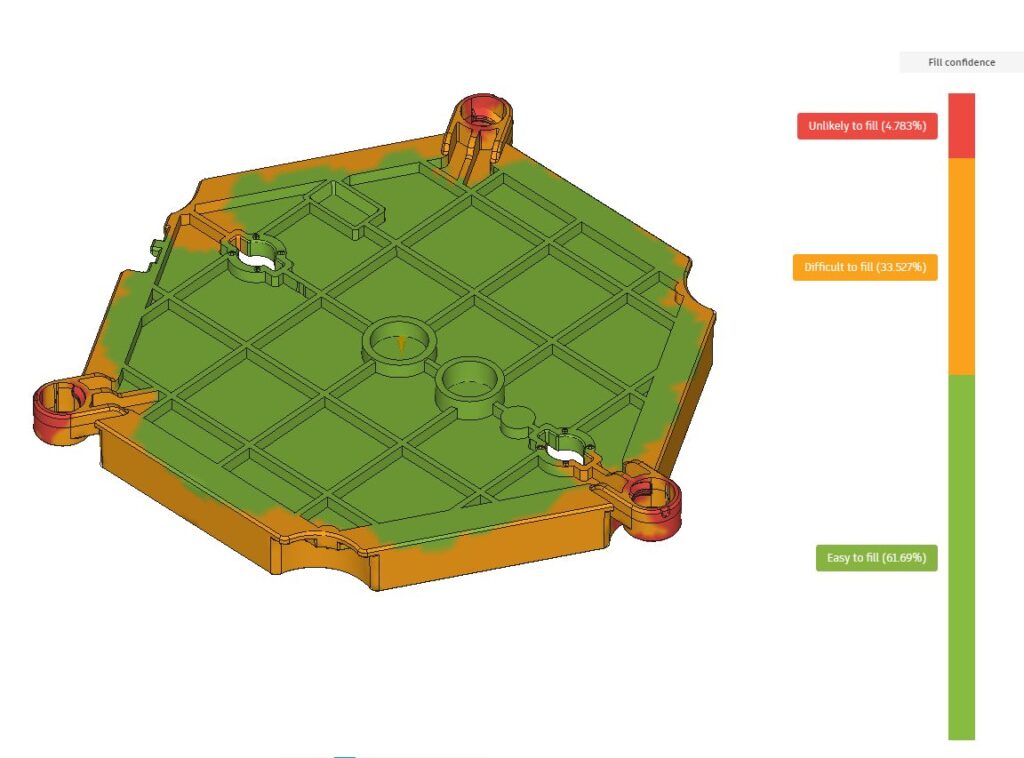

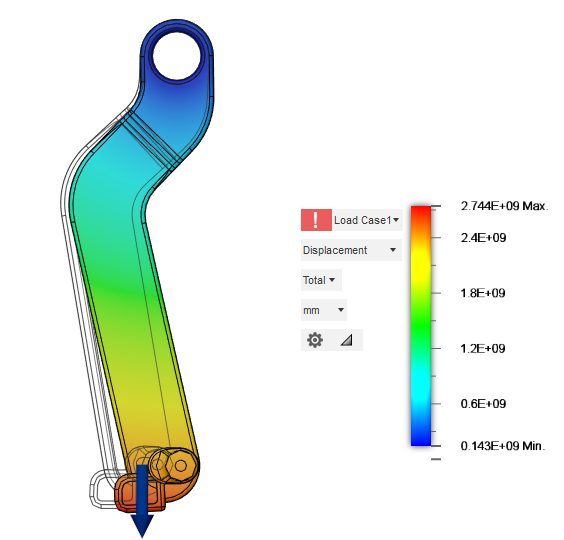

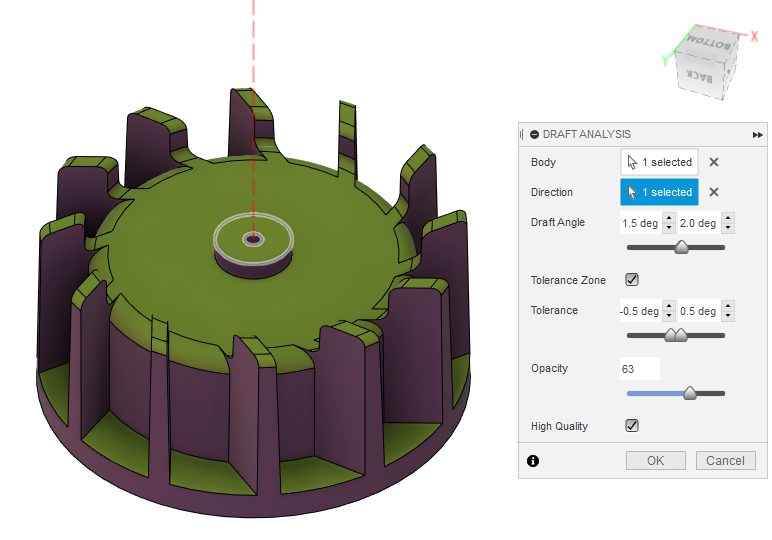

The product design and manufacturing process doesn’t end once a product hits the factory floor. During production, they may run into an issue with a molded part and can use the injection molding analysis tool and static stress study tools in Fusion to identify a solution. And, of course, additional feedback occurs once the toy is out in the real world.

“Even when products are out on the market, we carefully monitor any reviews, feedback from retailers, and calls to customer service for any reason,” Budd says. “It’s not uncommon for us to make very quick changes to the product and to try and solve anything unexpected.”

Moving product design and manufacturing to Fusion

Moose Toys is known for a key competitive advantage: agility and innovation. Over the last ten years, this has become even more critical to their success with their increased electronic components and mechanisms.

Budd first joined Moose Toys six years ago as a product design engineer and has been a product design manager for the past four years, working on the hands-on design of mechanical elements in the more complex toys. He quickly recognized the difficulties with collaboration, varying software use, and cost. Most of the team was using SolidWorks for any of the mechanical design work, and Budd himself had used the software for the past 12 years in his previous work for medical devices. Other designers were using Rhino for sculpting as well as ZBrush.

“Since there wasn’t much of an engineering focus or team when I joined, everything was very siloed to individual design teams,” Budd says. “We identified that as a bit of a challenge. We needed to get all the different designers to talk to each other and collaborate because it’s a nightmare trying to import files from something like ZBrush into SolidWorks. It just doesn’t work unless you paid for more expensive plugins and that kind of thing.”

Breaking down silos

With a growing team of new product designers and engineers, the licensing fees for software and add-on plug-ins were becoming cost prohibitive. “We identified the need for a better CAD package,” Budd says. “We did a bit of a hunt but aligned on Fusion pretty early on.”

Fusion provides the ability for Moose Toys designers to jump in and use the form tools to sculpt animals, action figures, and more. At the same time, the mechanical team can take that very same file and build mechanisms and electronics that go inside.

“Fusion offered a balance where there were enough tools for the mechanical design engineers to do what we needed to do, such as simulating mechanisms and designing all the gearboxes and linkages,” Budd says. “But it also still had the right tools for the product designers to be able to sculpt shapes.”

“With Fusion, we can execute several different functions within one package, and that has been the most important thing for us. We don’t have to use Rhino for sculpting or SolidWorks for mechanical design. We can do that with the same software and actually all work on the same file at the same time. It’s a huge benefit.”

— Carl Budd, Engineering Manager, Moose Toys

Collaboration and working in the cloud with Fusion

After years of working with SolidWorks and various software, Moose Toys has fully seen the benefits of moving to Fusion—all the way from concept and electronics design to manufacturing.

“The file management and cloud storage system in Fusion make it nicely centralized for us, rather than siloed CAD software at each office where we had to try and link without controls or revision management in place,” Budd says. “We’re able to keep it all in one place now, so everyone knows where to go for the most current version of a particular design.”

“We also have design history where everything is available as well,” he continues. “People can easily look up a past design if they want to borrow some design cues or a legacy OEM component. It’s great to have that ability.”

Another bonus to working with Fusion is the variety of tools, ease of use, and flexibility for individual functions and roles across Moose Toys’ teams. Setting up all the design rules means a designer can easily consider wall thicknesses or how radii will be affected by the plastic flow during the injection process. The engineering department uses the Product Design Extension with a number of tools for plastic design that are very useful, according to Budd. The KeyShot plug-in for Fusion is also helpful for renderings. Even the Fusion plug-in for Esko brings packaging designers into the fold.

With Moose Toys’ commitment to making kids “Superhappy,” Fusion is there to make it that much easier.