Material Requirements Planning (MRP) is a crucial system in manufacturing that optimizes inventory, production schedules, and supply chain management. MRP software like Autodesk Fusion Operations enhancing efficiency, accuracy, and collaboration through real-time data and advanced analytics.

In the realm of manufacturing, efficiency, precision, and timely production are paramount. To achieve these goals, manufacturers rely on various systems and methodologies. One such critical system is Material Requirements Planning (MRP). This blog delves into what it is, its importance in manufacturing, what MRP software entails, the benefits of using MRP software, key factors to consider when choosing an MRP solution, and how Autodesk Fusion Operations can play a pivotal role.

What is MRP?

Material Requirements Planning (MRP) is a systematic approach to calculating the materials and components needed to manufacture a product. It is designed to ensure that materials are available for production and products are available for delivery to customers while maintaining the lowest possible level of inventory. MRP aims to balance demand and supply by scheduling production activities, ordering materials, and managing inventory.

The core functions of an MRP system include:

- Inventory control: Managing the inventory of raw materials, components, and finished products to prevent shortages and excess.

- Production planning: Scheduling production activities to meet demand while optimizing the use of resources.

- Demand forecasting: Predicting future demand to ensure that materials and products are available when needed.

- Supplier management: Coordinating with suppliers to ensure timely delivery of materials.

Its importance in manufacturing

Material Requirements Planning plays a crucial role in manufacturing for several reasons:

- Optimized inventory levels

- MRP helps manufacturers maintain optimal inventory levels, reducing the costs associated with excess inventory and minimizing the risk of stockouts.

- Improved production efficiency

- By scheduling production activities and ensuring the availability of materials, MRP enhances production efficiency and reduces downtime.

- Enhanced customer satisfaction

- MRP enables manufacturers to meet customer demands promptly by ensuring that products are available when needed.

- Cost reduction

- Efficient inventory management and production planning lead to cost savings in storage, materials, and labor.

- Data-driven decision making

- MRP systems provide valuable insights and data that help manufacturers make informed decisions, improving overall business performance.

What is MRP software?

MRP software integrates various functions such as inventory control, production planning, demand forecasting, and supplier management into a single platform. MRP software leverages data and advanced algorithms to optimize material requirements and production schedules, ensuring that manufacturing operations run smoothly and efficiently.

Key features of MRP software include:

- Real-time inventory tracking: Monitoring inventory levels in real-time to prevent stockouts and overstock situations.

- Automated order processing: Generating purchase orders and work orders automatically based on demand forecasts and inventory levels.

- Production scheduling: Creating detailed production schedules to optimize resource utilization and meet delivery deadlines.

- Demand forecasting: Using historical data and predictive analytics to forecast future demand accurately.

- Supplier management: Managing supplier relationships, tracking delivery schedules, and coordinating material procurement.

Benefits

Implementing MRP software offers numerous benefits to manufacturers including, but not limited to:

- Increased efficiency

- MRP software automates manual tasks, reduces errors, and optimizes production schedules, leading to increased operational efficiency.

- Cost savings

- By optimizing inventory levels and production processes, MRP software helps manufacturers reduce costs associated with excess inventory, storage, and labor.

- Improved accuracy

- Real-time data and advanced algorithms ensure accurate demand forecasting, inventory tracking, and production planning.

- Enhanced collaboration

- MRP software facilitates communication and collaboration between different departments, suppliers, and stakeholders, ensuring a smooth flow of information.

- Scalability

- MRP software can scale with the growth of the business, accommodating increased production volumes and expanding operations.

- Compliance and traceability

- MRP software helps manufacturers comply with industry regulations and standards by providing traceability of materials and products throughout the production process.

Factors to consider when choosing and MRP solution

- Integration capabilities: The software should integrate seamlessly with existing systems such as ERP (Enterprise Resource Planning), CRM (Customer Relationship Management), and CAD (Computer-Aided Design) tools. This ensures a smooth flow of data across different platforms and eliminates data silos.

- Scalability: Choose a solution that can scale with your business needs, accommodating increased production volumes and additional users without compromising performance.

- Customization: Look for software that can be customized to fit your specific business processes and workflows. Also, customization options should be available without extensive coding.

- Cost: Consider the total cost of ownership, including software licensing, implementation, training, and ongoing maintenance. Also make sure that the software provides a good return on investment.

- Data security: Ensure that the software has robust security features to protect sensitive data from unauthorized access and breaches.

Fusion Operations, your MRP solution

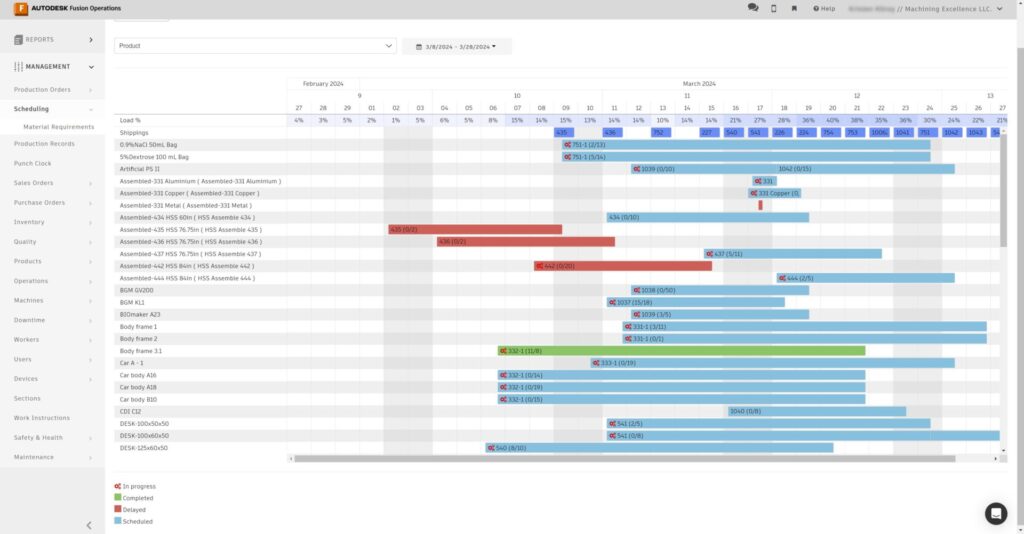

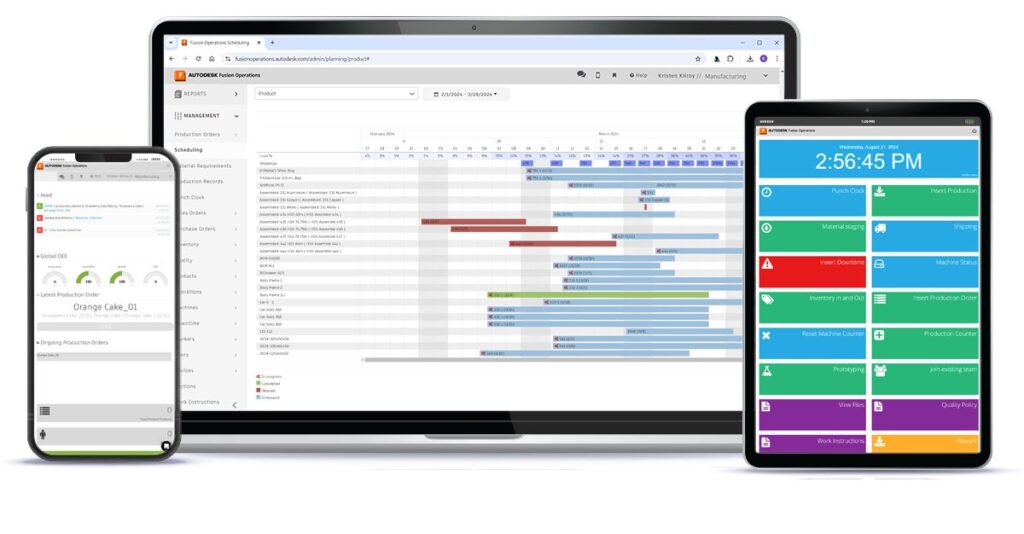

Autodesk Fusion Operations is a powerful tool designed to enhance manufacturing operations by providing comprehensive MRP capabilities. Here’s how Fusion Operations can help:

Integrated platform

Fusion Operations integrates seamlessly with Autodesk’s suite of design and manufacturing tools, providing a unified platform for managing the entire product lifecycle. This integration ensures a smooth flow of data from design to production, reducing errors and improving efficiency.

Real-time data

The solution provides real-time visibility into inventory levels, production schedules, and demand forecasts. This real-time data enables manufacturers to make informed decisions and respond quickly to changing market conditions.

Advanced analytics

The software leverages advanced analytics and machine learning algorithms to optimize material requirements, production schedules, and inventory levels. Ultimately, this ensures that resources are used efficiently and production goals are met.

Collaboration tools

Fusion Operations facilitates collaboration between different departments, suppliers, and stakeholders by providing a centralized platform for communication and data sharing. As a result, this leads to enhanced coordination and reduces the risk of miscommunication.

Scalability

Fusion Operations is designed to scale with the growth of your business. Whether you are a small manufacturer or a large enterprise, the platform can accommodate your needs and support your growth.

Customization

Fusion Operations offers customization options that allow you to tailor the platform to fit your specific business processes and workflows. This ensures that the software aligns with your unique requirements.

Security

Robust security features to protect sensitive data from unauthorized access and breaches. This ensures that your data is secure and compliant with industry regulations.

Conclusion

Material Requirements Planning (MRP) is a vital component of modern manufacturing, ensuring that materials are available for production and products are delivered to customers on time. MRP software automates and streamlines the MRP process, providing numerous benefits such as increased efficiency, cost savings, improved accuracy, and enhanced collaboration.

By leveraging the power of MRP software and solutions like Fusion Operations, manufacturers can optimize their operations, reduce costs, and enhance customer satisfaction, ultimately driving business success in a competitive market.