& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

9 min read

We generate over 40 million tons of electronic waste every year, and only 12.5% of that is recycled. Where does the rest end up? On the doorstep of some third-world country. The problem just isn’t the waste though, it’s what the waste does to our environment, and ultimately our health. Discarded electronics mix with acid rain, and there goes lead into a community’s water supply. But what are we to do? As a society, we use electronics and then throw them away with little regard for where they end up. This is why RoHS was made a law in Europe, to keep hazardous materials out of landfills once and for all. Here’s what you need to know about it as an electronics designer.

The Restriction of Hazardous Substances, or RoHS, became law in Europe in 2003 and restricts the use of hazardous substances in electronics after July 1, 2006. However, any repaired parts, equipment, or inventories marketed before 2006 are exempt from this law. The restricted substances that RoHS govern includes:

Of these six, lead gets the most attention in the world of electronics manufacturing, and for a good reason. In the past, lead was used in nearly all solder to attach components to bare boards during assembly, and the most common surface finish before RoHS arrived contained 40% lead.

These days, everything has changed in the world of electronics manufacturing. You might be hard pressed to find a component that is available in lead, and there’s a variety of lead-free finishes to choose from for your next design project. But what does all of this mean for you, the electronics designer, and your manufacturer?

Of the six restricted substances in RoHS, the removal of lead has presented the greatest challenge for electronics manufacturers. Why?

Lead-free solder requires a higher melting temperature at 441°F, compared with a traditional tin/lead solder which melts at 356°F. Components also need to be able to withstand this higher temperature which can completely change how they’re designed and manufactured.

Since lead and lead-free boards require completely different temperatures, this also requires separate manufacturing processes. This can add up to an enormous investment in machinery when your local fab house has to operate two manufacturing lines, one for leaded and one for non-leaded electronics.

Removing lead doesn’t just affect the producers of electronic equipment. The line of responsibility trickles down to where materials and source from, and from who. These days you’ll typically find certificates of compliance as a mandatory requirement from any and all electronic supplier doing business with a producer.

RoHS affects nearly all aspects of the electronics manufacturing process. Digging a little deeper into the manufacturing workflow, you’ll find RoHS influencing nearly every step of the production of your PCB, including:

By now you might be wondering, what does all of this RoHS stuff have to do with me, the designer? If a manufacturer has to meet RoHS requirements, won’t they just choose a lead-free finish and make sure they’re using only lead-free parts? Not quite. Unless you want your board to get held up with unnecessary production delays, then RoHS introduces a ton of new variables to consider in your design process, including:

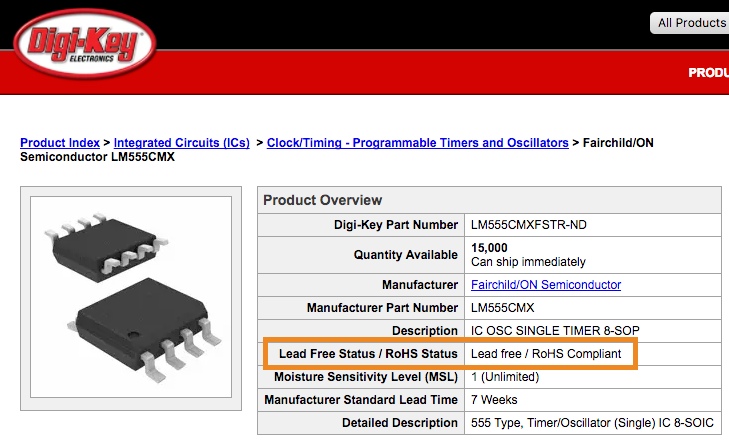

Before your board is ever manufactured, you the designer are responsible for picking parts that are RoHS compliant. Thankfully most if not all component distributors clearly identify whether a component is RoHS compliant on their website. For example, over at Digikey, you’ll notice a green leaf symbol next to each part in the search results. When you view the specs for a specific part, there’s also a Lead Free Status/RoHS Status at the top of the page to guide your part choice decision.

In addition to choosing RoHS compliant components, you also need to consider whether your parts can survive the higher temperature required for melting lead-free solder. For temperature sensitive parts like MEMs, switches, membranes, and LEDs, we recommend making notes in your Bill of Materials (BOM) for your assembly house, so they know up front about the temperatures constraints.

You’ll also need to be in charge of selecting a lead-free finish for your PCB, and there’s a ton of options to choose from. This can be a challenging decision to make, as there is no universal “best” option out there. What you’ll find is that every finish has its unique advantages and disadvantages, which need to be balanced with your unique design requirements. The most popular lead-free surface finishes to consider includes:

Electroless Nickel Immersion Gold is made from a bottom layer of nickel with a thin layer of gold on top. This top layer of gold acts as the protective coating of the nickel.

Advantages

Disadvantages

Organic Solderability Protectants covers the copper surface of a board with a very thin organic compound layer. This water-based compound is a well known, environmentally friendly finish option.

Advantages

Disadvantages

Immersion metal comes in two forms, tin or silver. Boards that have their components assembled by machine will typically use this surface finish.

Advantages

Disadvantages

Lead-free HASL, or Hot Air Solder Levelling, is the most popular lead-free finish available. This application is applied by dipping a board into molten solder and then blowing off any excess solder with hot-air knives.

Advantages

Disadvantages

When working with your manufacturer, it’s important to not just ask for a lead-free finish. Instead, go the extra mile and confirm that your fab house is using finish materials that can handle multiple passes through an oven at higher temperatures, all while meeting your specific component temperature requirements.

All RoHS compliant components will come in a moisture protective package with an expiration date. If you end up using an expired component past its expiration date, then it’s likely to be damaged during the fabrication process due to expanding water vapor. If you’re planning on sending components to your assembly house, then be mindful of both the integrity of your moisture protective packaging and also the listed expiration. You’ll need to let your assembly house know about any opened or expired parts so they can bake the components to remove any excess moisture.

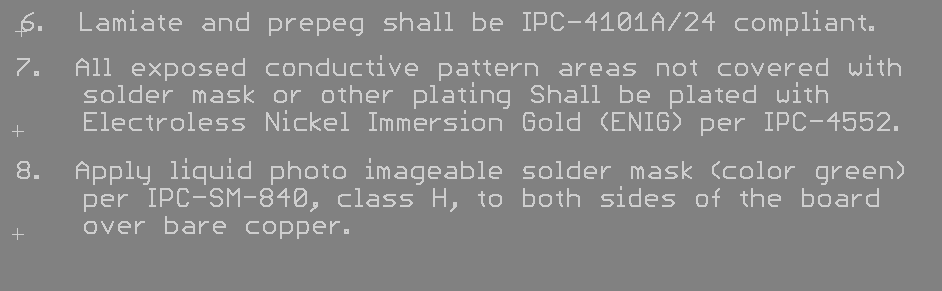

It’s important to always make a note of non-RoHS specific attributes for your design on both your assembly and bare board drawing. Since RoHS is now the norm instead of the exception, this makes it much easier for your manufacturer and fabricator to choose the right materials and processes for your design. For example, the fabrication notes in the image below have a specific callout about the required finish.

The guidelines we’ve recommended so far won’t have much of an impact on your PCB layout process. This is good news, as most traditional PCB layout methods will transfer seamlessly over to RoHS compliant boards. However, we do recommend tenting (solder mask fully enclosed over the via opening) both sides of a via hole on your layout to avoid any outgassing during the high-temperature assembly process. You can also avoid the popcorning effect on moisture-sensitive components like BGAs and PBGAs with an aggressive via fan-out pattern.

RoHS compliance is the norm in the electronics design and manufacturing industry. If you’re a hobbyist, you most likely won’t be worrying about RoHS. However, the minute you start working on a project that will be produced and marketed in Europe you’ll need to make sure your product is RoHS compliant. Your manufacturer will be able to provide a certificate of compliance if your product requires it, and you’ll also find all RoHS compliant products with their own unique label. There’s no specific labeling standard, so expect some variations.

At the end of the day, RoHS compliance doesn’t just fall into the hands of your manufacturer. You need to be on top of choosing lead-free components, selecting the right lead-free finish, and adding all the necessary details in your documentation notes to make your manufacturer’s life easier. It’s a team effort here, between you and your manufacturer to make the world a less toxic place.

Ready to design your first RoHS compliant PCB? Try Autodesk EAGLE for free today!

By clicking subscribe, I agree to receive the Fusion newsletter and acknowledge the Autodesk Privacy Statement.

Success!

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.