Talk to Dr. Casey Kerrigan for five minutes, and you can’t help but understand the passion she brings to her work. She has spent decades studying the biomechanics of the human foot and leg as we walk, run, jump, or simply stand, using that research to dispel old myths about how the body functions and how our shoes should be built.

Kerrigan, who ran track in college herself, wasn’t content to stay in the lab when she saw so many people, especially women, suffering avoidable injuries and arthritis, so she set out to make a better shoe. In building her company OESH, she has done not only that, but also reinvented the shoe manufacturing process, not to mention her own career as a physician and scientist.

Rebuilding Athletic Shoes from the Inside Out

The name OESH, which is pronounced like the beginning of “ocean,” is the word SHOE turned upside down and inside out. True to its name — and Kerrigan’s research — the company aims to turn our understanding of sneakers inside out, too.

One of the fundamental insights that Kerrigan developed with her research teams at Harvard Medical School and the University of Virginia is that we have previously misunderstood how running and walking affect the body. Typical running shoes are built with so much cushioning and an elevated heel because they are based on the incorrect assumption that impact is greatest at the moment the foot strikes the ground.

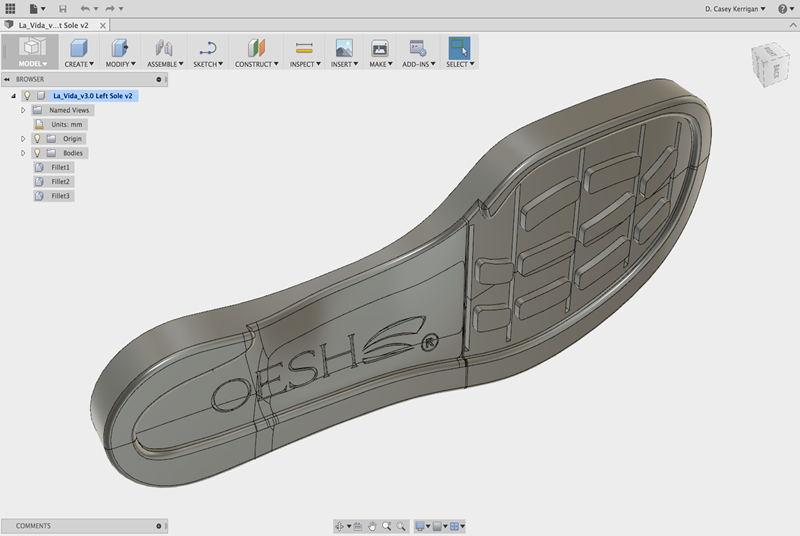

Using 3D motion analysis and 3D robotic modeling, Kerrigan determined that the forces on our joints are actually higher a split-second later, when the foot is fully planted. Beyond that, traditional running shoes actually make those forces worse, not better. What’s needed is a new kind of shoe with a perfectly flat sole.

New Shoe, New Career

Like other physicians, Kerrigan knew that putting patients in better shoes could directly address their joint ailments. But whereas other doctors said “there’s nothing available” and left it at that, she set out to make it happen.

She knew she could not fulfill her vision if she remained a full-time professor. “There’s no room for a technologist in the typical university academic setting,” she says, so she gave up her academic job to take on the challenges of being an entrepreneur.

“Setting up a business is the hardest thing I’ve done, for sure,” she says, “harder than medical school, or residency, even.” These days, she still teaches one course at UVa, but now it’s the first industrial design course offered by the university’s architecture school, and it fits in alongside her more-than-full-time role leading OESH.

Rethinking Shoe Materials and the Manufacturing Process

Most running shoes are made in China in factories that are great at traditional injection molding. But Kerrigan needed a different manufacturing process to accommodate the specialized materials she wanted to use. “We basically had to reinvent how they’re made,” she says, “and that took doing it here.”

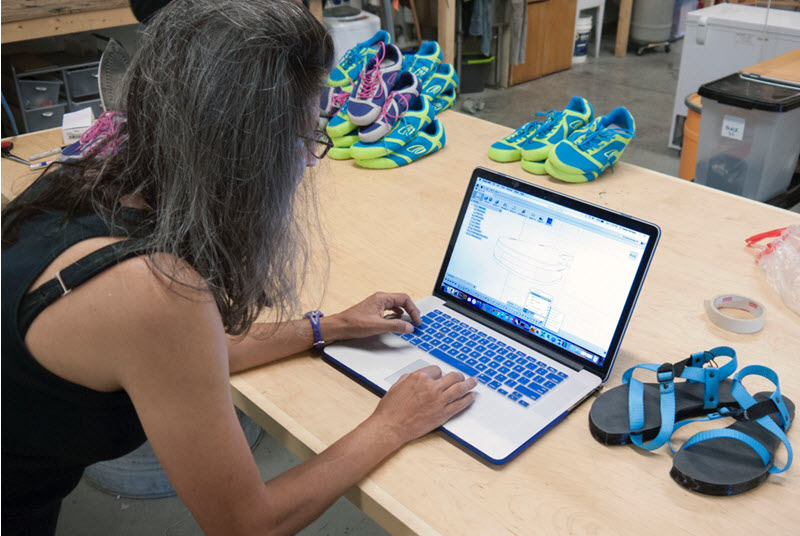

For starters, Kerrigan and her team have used Fusion 360 for the design of the shoes themselves. “That sculpt mode is really terrific,” Kerrigan says, adding that she would eventually like to use T-splines to customize the fit of her shoes’ uppers for each customer. She also dreams of customizing the biomechanics of each shoe based on the wearer’s weight and stride length.

The sole of OESH shoes is made from a mix of carbon fiber composite and other materials — a proprietary formulation that Kerrigan has been refining for many years. Existing 3D printers couldn’t handle the material properly, so Kerrigan and her team have gone even deeper with Fusion 360 by using it to design custom 3D printers for their own purposes.

“It’s not your typical desktop printer running with filament,” she says, noting that her printers handle essentially all of the materials used in injection molding. Designing the printers herself has also allowed her to keep the manufacturing process cost-effective in terms of scale, speed, and the efficient use of materials.

A Return to Hands-On Manufacturing

Kerrigan believes that in many ways we have lost the art of manufacturing. The OESH team is reclaiming this by doing things themselves in central Virginia, designing and building their own tooling as needed to achieve what they want with their shoes.

“The actual process of making is not trivial,” she says — a point she tries to get across to her design students. Her students will come up with “really cool-looking, awesome shoe designs” in her course, but she challenges them to think through the questions that arise in manufacturing: “How are you going to make it strong enough to be practical? How are you going to figure out the tooling so that you can make a lot of them?”

She laughs as she quotes the mantra of a colleague: “If it were easy, everybody would be doing it.”

The Satisfactions of Entrepreneurship

OESH recently began making sandals, the Athena collection, proving the concept that soles can be 3D printed for mass customization. Meanwhile, their La Vida sneakers continue to sell more and more. When we interviewed Kerrigan, she and her colleagues were prepping their production line for a typical run of 1,000 pairs.

So far, the business has focused on perfecting the design and manufacture of the shoes, relying mostly on word of mouth for marketing. That approach has been successful, especially because the shoes continue to draw raves from the “OESHers” who swear by them. (Although the shoes will also fit men, they’re designed primarily for women, who experience twice as many joint injuries in the foot and lower leg as men do.)

Kerrigan is obviously proud of the effect her shoes have on her customers: “If I can make those women happy and give them the next really good product, I feel great.” She adds that she evaluates each new idea by asking herself, “How are our current OESHers going to like this?”

The direct feedback from customers tells her that her vision has become a reality. “I feel good about what I’m doing at this point as a physician,” she says, adding that “I feel like I’m still doing science.”

And as hard as the work is, “We sleep well at night knowing we’re doing the right thing.”