Elevate your design and manufacturing processes with Autodesk Fusion

Usually, I start my blogs with something like, “it’s not often you meet” or “people like this are a rare treat.” I’ve recently realized that while those statements about these people are very accurate, I am quite fortunate to meet these folks quite often, but they are still quite extraordinary.

Then someone like Blaise comes along, and extraordinary takes on a whole new meaning. Blaise Barrette appeared on the Fusion 360 radar when we first noticed him proactively commenting in our live streams to answer questions from customers, quicker then we could do ourselves. Then he came out with a 98% proficiency score on the command map, and we had to find out more about Blaise, and we weren’t disappointed.

Blaise is one of those polymath savants you meet, maybe 4 or 5 times in your life, excelling at everything they do. Based in Quebec, Canada, Barrette tells us he’s had many professions, such as working at a timber mill while also designing websites and working on media projects concurrently. Then he was a video editor; he had his own multimedia company, specializing in underwater imagery; and then used those web design skills to design a site called the Aquatic Biodiversity Monitoring Network that evolved into a non-profit organization.

Here is where it really gets interesting. Blaise’s house burnt down seven years ago, so he decided to learn how to design homes and rebuilt his house from the ground up. Including developing a lot of the furniture used to furnish the home with his girlfriend. As he describes it, “I absolutely loved building my house! It felt very rewarding”.

Like I said, polymath.

But wait, where’s the making?

Well, about five years ago, Blaise got into 3d printing, and if any of the above is any indicator, it should come as no surprise that he managed to produce some very viral content around this newfound passion of his. From there, he caught the digital fabrication bug and wanted to get into machining, but this is Blaise we’re talking about, so of course, he had to build his own machine.

Finally, all the pieces had fallen into place, Blaise has a history of getting things done, adapting to any new challenge, and excelling at it. The design heavens parted open, and the divine rays of manufacturing had found Blaise, and Blaise found Fusion 360.

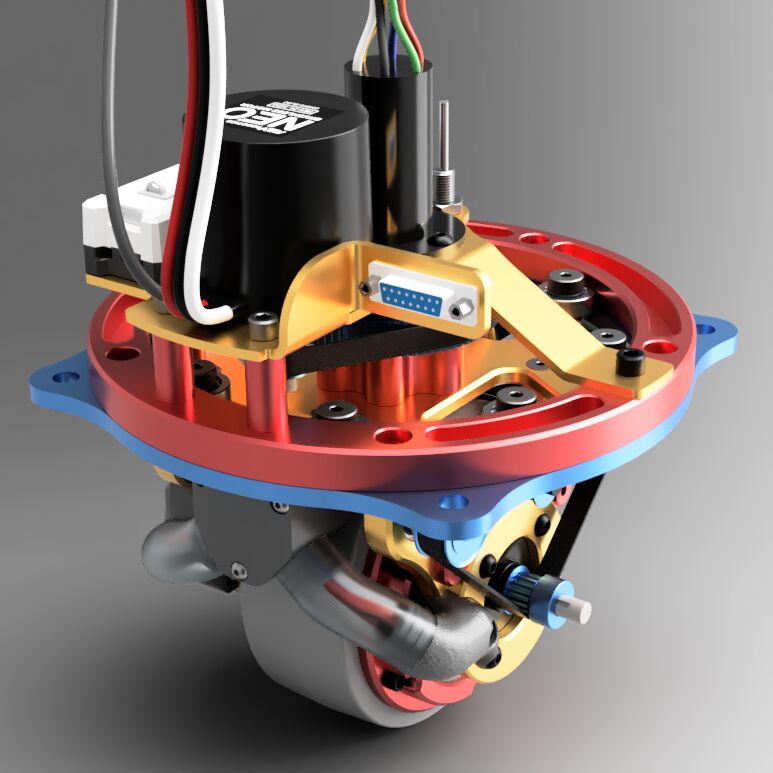

iPad support for DJI Mavic Pro remote.

The Awakening

The funny thing is, Blaise attributes using Fusion 360 to awakening the manufacturer in him, just don’t tell him he’d been one this whole time. Once Blaise was up and running with Fusion 360, everything turned up to 11. He and his son launched a FIRST robotics team, taking the Rookie All-star Award in their first year, hitting silver in the regionals, and now, have grown the team to 20 people.

Blaise gives classes of Fusion 360 to his teammates every year, and took all that content and uploaded it to youtube in French, specifically to help out his fellow French speakers get up and running with Fusion 360 (which btw, Fusion 360 now available in French!)

So what about today?

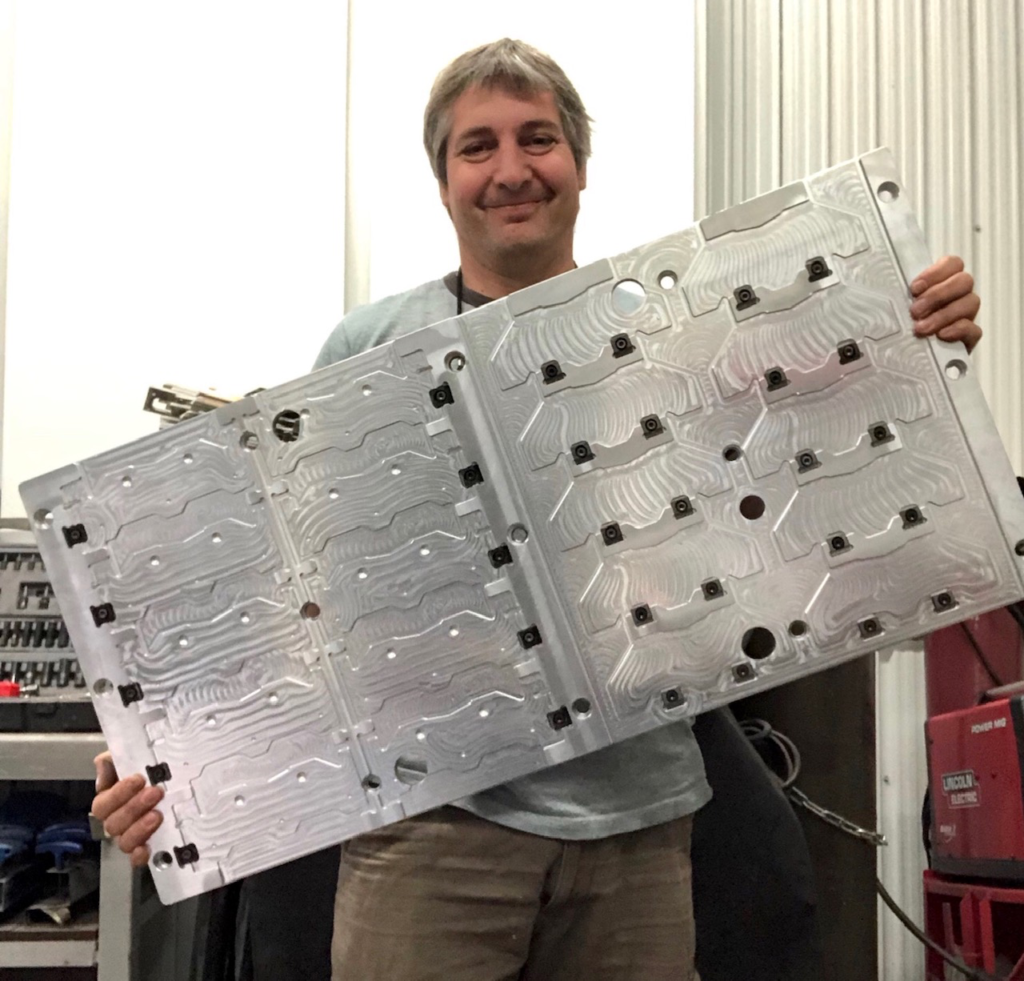

Well, Blaise claims Fusion 360 changed his life, I’d like to think Fusion 360 just helped him unlock the potential he always had. Two years ago, based on the skills he had built up with his own CNC machine, he was hired at a machine shop, where they were using SOLIDWORKS and Mastercam, and in less than two years, totally changed how they do the production. By switching to Fusion 360, Blaise says their office increased output by over 100%, and runs all the machines in the shop himself as part of his duties, from design to tool path to operations.

Blaise is still very much at it with the machining and designing, and the funny thing is, you’ve probably known about his work for years, you just didn’t realize it. Recognize this?

Yup, that’s one of Blaise’s models. You may not know that this is an upcoming part of his custom CNC machine at home. When I asked Blaise what’s up to today, he told me,

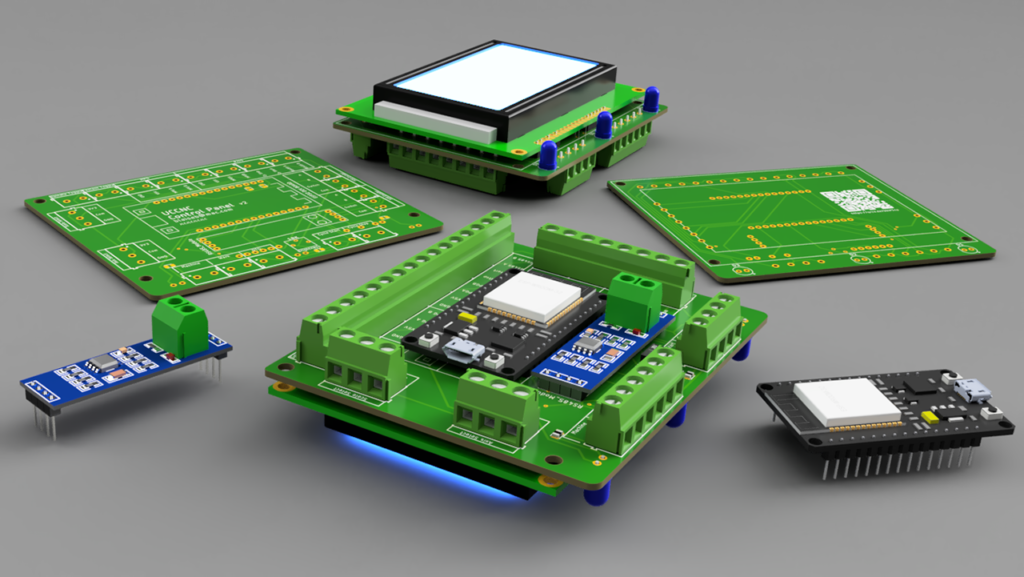

“Work has slowed down a lot with the pandemic. This leaves me with a lot of time to work on my CNC projects. I am working on the control panel and the electronics part of the CNC. This was the perfect project to learn the new Fusion 360 electronics! I am super excited about the new ECAD environment and the way it integrates with the other environments! At nearly 50 years old, I designed my first PCB in no time and had it made in China for a few bucks and voilà! This opens up so many possibilities!”

So to Blaise, we say thank you, for being such an incredible person, with an unflappably positive attitude, a thirst for knowledge, and desire to learn that is unparalleled. And to you, all of our Fusion 360 users and community out there. We know that Blaise’s story is unique in the specifics, but there are hundreds of you out there, changing your own lives, the lives of those around you, and making the world a better place, all through Fusion 360.

This one’s for the doers out there, unencumbered by doubt, driven by a passion for making, we hope to share your story here soon.

Start your innovation today, and download Fusion 360 today!