Here’s the problem: You want to hit the water in a kayak — but where are you going to store the thing when you’re not using it? And how are you going to transport such a long boat from home to the water?

Oru Kayak has solved that challenge with a line of tough, cleverly designed boats that fold up into a package the size of a small suitcase — one you can stow in the trunk of your car or sling over your shoulder. It’s all part of their vision “to make paddling more convenient, fun, and freeing for everyone.”

A Kayak Born in a California Garage

Oru Kayak is the brainchild of Anton Willis, an avid kayaker with a background in architecture who owned a long sea kayak but had a hard time storing it when he moved to San Francisco. After reading an article about origami (“oru” is the word for “fold” in Japanese), Willis began tinkering with the idea of a kayak made of highly resilient material that could fold up into a small space when not in use.

Over the course of five years, Willis went through 25 iterations of his boat, finally achieving a prototype he was happy with. As the company’s director of marketing, Andy Cochrane, puts it, “It’s fortunate for us that [Anton’s personal need] overlapped pretty heavily with a broad need within the niche of kayaking.”

From Kickstarter to Full-Fledged Company

A 2012 Kickstarter for the kayak raised $600,000 from 770 backers — at that time the largest Kickstarter campaign ever for an outdoor-product. When Willis was ready to set up the company, he brought on his friends Ardy Sobhani (CEO) and Roberto Gutierrez (chief commercial officer) as co-founders who could complement his own skills. For almost two years, any other work was handled through contracting or part-time arrangements. In the past year and a half, though, the full-time team has grown to ten people working across design, operations, and sales and marketing.

Several members of the staff have serious paddling backgrounds. Gutierrez, for example, was previously a professional surf kayaker. Similarly, Cochrane has been paddling since he was a small child, and he worked many summers as a professional whitewater guide.

Oru Kayak shipped its first orders in May 2013, and has more than doubled its volume and revenue every year since, with about 10,000 boats shipped to date. They’ve also learned to manage the balancing act of selling direct to consumers at the same time they sell through major retailers such as REI and L.L. Bean.

Building Boats for All Sorts of Paddling

The team’s long experience on the water has helped the company create a diverse product line to meet the needs of any paddler. The company’s first model, the Bay, is a 12-foot boat that’s a jack of all trades. It performs well enough to satisfy experts, but it’s versatile enough that beginners can use it for recreational paddling and touring as well.

“The overall theme is to make water more accessible,” Cochrane says. That means getting novices on the water, period, while also aiming to “do new badass things for the expert paddler.”

The company’s challenge now, he adds, is “to not just be good at everything, but nail each category.” The newer Coast series features longer boats designed for more stability in bigger waves, while the Beach model caters to recreational paddlers by being the lightest and fastest to set up.

All of the boats are made from a custom polypropylene — rated to 20,000 folds — that’s commonly used in architecture and industrial applications. While some customers initially questioned the boats’ durability, the team has demonstrated it time and again, for example with this video showing the kind of punishment each kayak can take. Now, Cochrane says, customers spend much more time asking “Does this boat fit my lifestyle?”

“That’s a cool turning point for us,” he says.

Clever Design Developed through Many Iterations

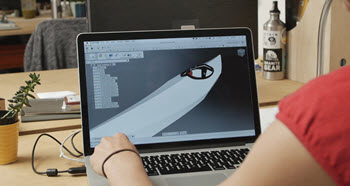

Oru Kayak’s design team has now grown to four people: Willis, two engineers, and a product designer. Their focus has shifted from early-stage design toward the specific challenges of engineering and manufacturing. The point is to optimize both the user experience and the efficiency of production.

Oru Kayak’s design team has now grown to four people: Willis, two engineers, and a product designer. Their focus has shifted from early-stage design toward the specific challenges of engineering and manufacturing. The point is to optimize both the user experience and the efficiency of production.

“It starts with design philosophy,” Willis says. “You have to be willing to make guesses, not get too attached to ideas, and change on a dime based on user feedback.”

Fusion 360 has been integral to streamlining that process. “We began by using Fusion 360 to roughly model the kayak and parts, to visualize how pieces came together,” Willis adds, “but we were still using CNC and other technologies to make the parts. Now, we’re revising many of the kayak parts with new injection molds” using Fusion 360.

kayak parts with new injection molds” using Fusion 360.

“We are making the individual parts more efficient to manufacture, stronger, and more consistent with the overall aesthetic of the product — fluid, clean, and simple,” Willis says. “For combining these elements, it’s been crucial to have software that’s rigorous but allows for flexible and intuitive sculpting in three dimensions.”

The level of detail required can seem exhausting, but Willis believes the payoff is worth it. “The last 20% of any design takes 80% of the time,” he says. “We’re working on things that customers may never even notice, but dialing them in for efficient manufacturing and user interface that’s so clean that you never think about it while you’re using it.”

Paddling into the Future

Today, the company’s efforts are geared toward increasing volume. Cochrane points out that the outdoor recreation industry is predicated on selling successfully through large retailers. “To do that,” he says, “we just need to make boats a lot faster and somewhat cheaper.”

As Willis and the rest of the design team refine the design for manufacturing, the company is looking to increase the production in its Pomona, California plant from dozens to hundreds of units each day. And as they continue to get great feedback from users, they expect to make new optimizations for each kayak model year by year.

For Cochrane, their focus on getting it right is compelling: “We’re pretty proud of that boat, and pretty confident it will change the game.”