Elevate your design and manufacturing processes with Autodesk Fusion

Looking to get more out of Fusion 360? Our hardware and software partners provide all sorts of benefits and resources exclusive to Fusion 360 users. Today, we’ve invited Ezra Spier, Vice President of Software Product at Other Machine Co., to share how he’s seen Fusion 360 used in the world of engineering education.

Think back to your favorite classroom memories from when you were in school. Do you remember the lectures? Textbook chapters? Challenging problem sets? I’d be willing to bet that your best and most useful learning experiences were hands-on: when you had the chance to dive deep into a problem and apply the concepts you learned to solve it.

For me, it was learning the difference between position, velocity, and acceleration in high school physics class. I had read the textbook chapter and finished the problem sets, but the concept didn’t fully gel until my teacher set up a small radar sensor that visually graphed my body’s motion over time as I moved around the room. He challenged me to walk from the back of the room to the front while increasing my velocity. No sweat: I just made sure to gradually increase my walking speed. Then, he told me to do the same thing, but to increase my acceleration. This time, there was sweat: I was running fast by the time I got to the other side. It was a simple task, but that was the moment that I truly understood the concept. The hands-on (or in this case, feet-on!) exercise made the ideas come alive.

Other Machine Co. (makers of Othermill, desktop CNC mill) is passionate about inspiring hands-on education anywhere we can. We work directly with educators who have truly taken this idea to heart. In programs as diverse as engineering and studio art, educators are using super soakers, Lego, electronics, and other technology tools to enhance their teaching. We’re especially excited to see how college professors have begun to harness Fusion 360 and the Othermill to bring hands-on learning to Mechanical Engineering students.

Here’s a great example. Undergraduate Mechanical Engineering students spend at least one semester learning Statics– the study of mechanical systems in equilibrium. These concepts are critical for designing bridges, buildings, and anything else that’s supposed to support large loads. In classes, students typically learn how to analyze and design static systems, but rarely get hands-on experience.

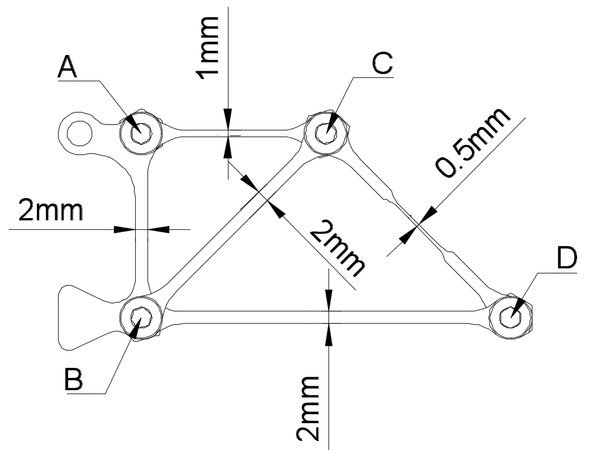

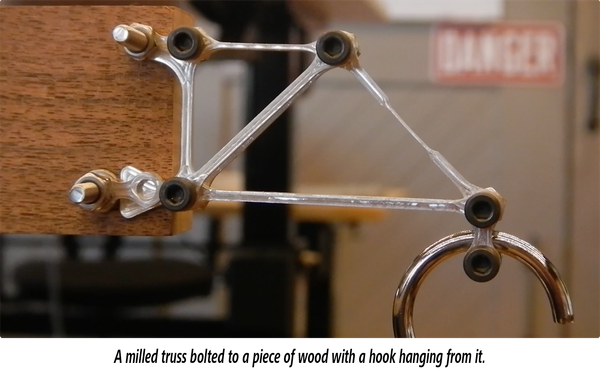

In one common Statics exercise, students learn to design and analyze the forces in trusses. Trusses are part of structures like bridges, radio towers, and marshmallow-and-toothpick models. Usually, these exercises start and end with rigorous paper problem sets. But with Fusion 360 and the Othermill, it doesn’t have to end there.

In the Othermill truss lab, students don’t just analyze on paper. They design their own truss parts in Fusion 360 and then use the CAM functionality within Fusion 360 to set up the toolpaths needed to manufacture their part. Students then use the Othermill to mill out the parts so that they can test their designs by stretching the metal until it breaks. As a bonus, they can also verify their analysis using Fusion 360’s Finite Element Analysis Simulation features. These are the same tools that engineers in the industry use every day, and are finally easily accessible to students.

If you’re interested in using this lab experiment in your own classroom, you can download it for free from our website.

This project just scratches the surface of what’s possible with Fusion 360 and the Othermill. We’re working on additional educational resources for mechanical design, electrical engineering, and more. Read more about the Othermill here, and take a look at our Fusion 360 Resources blog to get started right away.

With Fusion 360 and the Othermill, students have an accessible, affordable, and simple way to experience their engineering projects first-hand. We’re excited to continue to demonstrate the many ways CNC machines and 3D CAD tools can enhance and accelerate engineering education.