Everyday App Note: Dispelling the Myth of Passive Components

We live in a black and white world of engineering. There are active components and passive components, 1s and 0s, right? We all know about active components, parts like transistors and integrated circuits (ICs) that interact directly with signals and power supplies. But what about those passive components like capacitors, resistors, inductors, etc? Are they really just sitting there inert? Nope. This three part Everyday App Note series from Maxim Integrated dispels the passive nature of passive components by focusing on their parasitic qualities.

The Capacitor

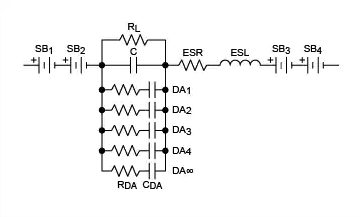

This app note series begins by looking at the active role of capacitors and their parasitic qualities. Take for example the circuit below. You might assume the job of this capacitor is to simply hold and release a charge, but when placed with several other passive components interesting behavior begins to happen.

The equivalent series resistance (ESR) of resistor RL can affect how well the capacitor can reduce ripple and pass high-frequency signals. This in turn makes the capacitor inductive and unable to decouple high-frequency noise from the power supply to ground.

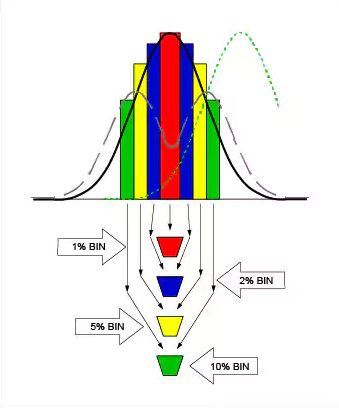

There’s also the issue of the manufacturing quality of a capacitor. The lower the quality, the larger the tolerances. This all leads to a deviation and possible issue if low-quality capacitors are used to set the time or frequency in a system. The image below shows the standard deviation of a manufacturing process and how the tolerance fluctuates with quality.

The Resistor

The simple resistor, or so we think. Truth be told, the quality of manufactured resistors can vary widely. Some manufacturers produce resistors with large variations in tolerance. Other focus on price over quality. Or if you’re Dr. Zandman, a zero-tempco resistor focuses on precision. Point being, the inaccuracy of manufactured resistors introduce small parasitic errors into our design.

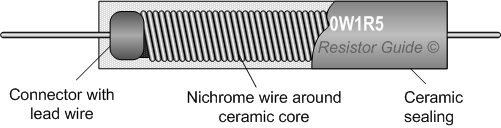

Take for example wire-wound resistors. These are often chosen by engineers because of their low temperature coefficients. However, their physical structure can often react with magnetic fields. This leads to what was once a passive component actively producing crosstalk.

The PCB

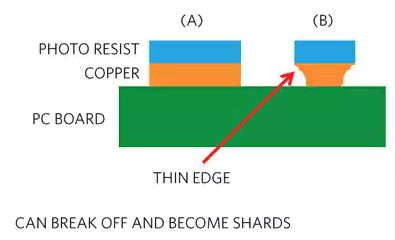

Then there’s the PCB itself, which at a glance might appear to be a standard square or rectangular structure that supports all the components. But take a closer look and what you’ll find is an amazingly complex structure of layered materials. We all know the manufacturing process for PCBs is anything but perfect.

Take for example when a board is over-etched. When this happens, tiny shards of copper are displaced on the board and can actively cause random shorts. What happened to the PCB just being a passive foundation?

Read These App Notes

This app note series is a great read for expanding the perspective of active and passive components. Who knows, next time one of your boards isn’t working properly it might just be one of the “passive” parts at work! This app note series is split up into three parts: