& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

6 min read

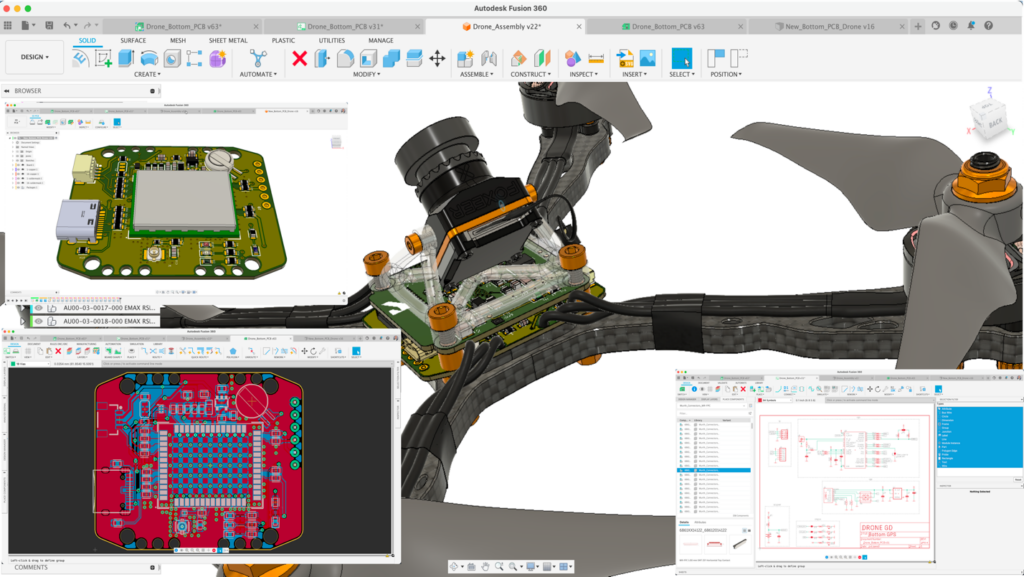

Autodesk Fusion Electronics has evolved into a powerful, intuitive, and high-performance PCB design solution that seamlessly integrates electronics, mechanical CAD, and simulation in one platform. With faster performance, AI-driven automation, and real-time collaboration, Fusion simplifies complex designs, ensuring precision and efficiency from concept to production.

If you’re exploring options for PCB design, Autodesk Fusion electronics should be at the top of your list. This isn’t just another design tool; it’s a game-changer for electronic designers, and if you’re designing consumer products, this is the solution you’ll want to use. Here’s why.

Fusion electronics has reached a whole new level, and it’s faster and smarter than ever. Our developers have worked closely with our XD experts to refine the interface, making it far more intuitive and easier to use. But it’s not just about looks. Take a look at these significant performance enhancements:

Instantaneous updates – Thanks to advanced polygon calculations, PCB modifications are applied in real time

Enhanced via stitching – This feature improves signal integrity, thermal management, EMI shielding, and structural strength in PCBs.

Smarter interactive routing – New automation tools like QuickTune that streamlines length tuning, giving you greater control over trace adjustments.

There was a recent forum post called QuickRoute the best-kept secret in Autodesk Fusion for electronics —and for good reason. This powerful feature speeds up PCB layout routing by automatically generating or optimizing trace paths with precision and ease. Whether you’re working with a single trace or an entire group of signals, QuickRoute helps streamline your workflow.

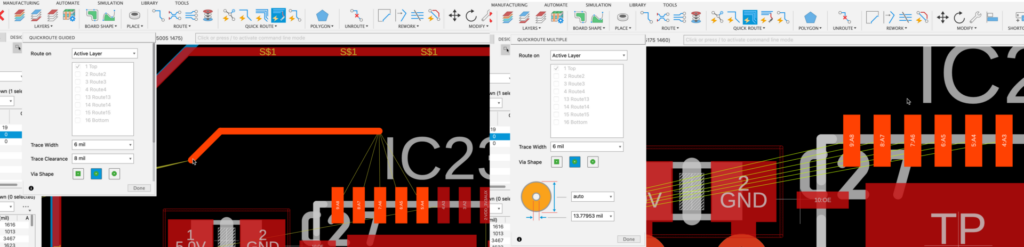

QuickRoute offers two group routing methods:

Guided routing is especially useful for bus routing, where you need to route multiple signals simultaneously while maintaining control over their paths. Personally, I prefer Group Route Guided, as it gives me more flexibility in defining the intended trace paths.

One of my favorite tools—one I use daily—is QuickRoute smooth. While I sometimes rely on the Autorouter and refine the results afterward, QR smooth takes routed traces and optimizes them by finding a shorter path with fewer bends.

For large designs, this tool is invaluable. Routing is an art, and while there’s no single “right” way to do it, QuickRoute Smooth helps achieve cleaner, more efficient layouts.

QR Fanout is an essential tool used to create fanouts of specific signals over short distances, ending in a via. A common use case is connecting a ground signal to a ground plane, ensuring solid electrical performance with minimal manual effort.

By leveraging QuickRoute, you can speed up PCB layout while maintaining full control over trace paths. Whether you’re routing manually or optimizing an existing design, these tools make the process faster, smoother, and more precise.

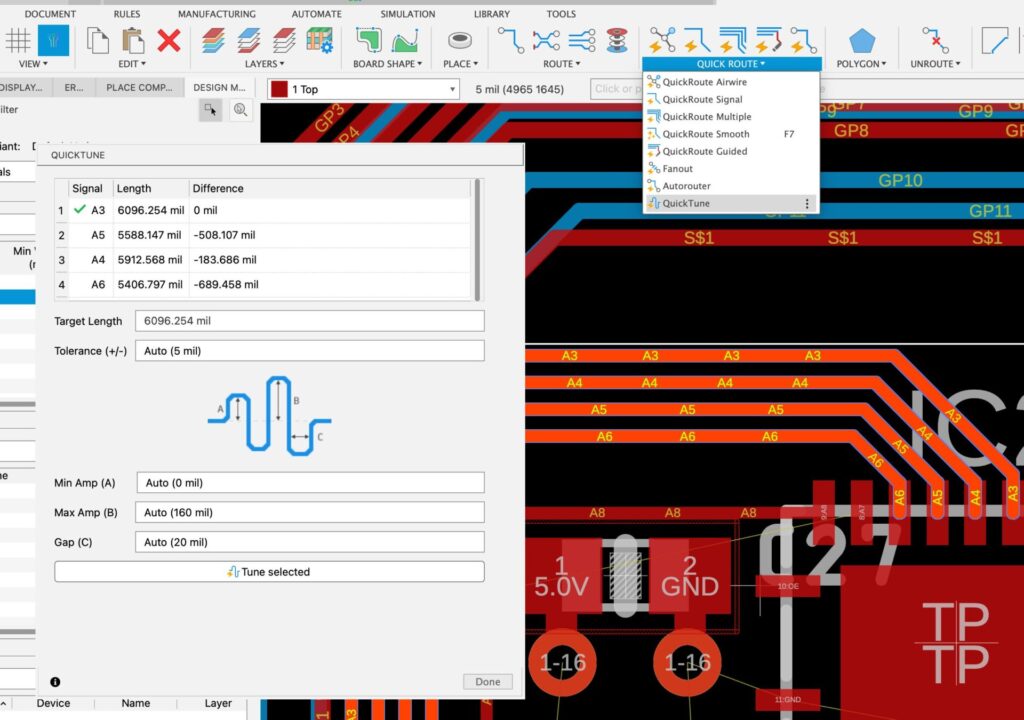

I want to end this section with our latest member of the QR family which is QuickTune. QuickTune is our automated length-matching tool. It can be used for a trace of a group of selected traces. If you choose a group of traces, it will attempt to meander all the selected traces to match the longest trace. You can specify the length of the single or group of traces. You can also select the meander’s Min and Max amplitude and gap. A meander is a powerful tool used to facilitate signals to reach their destination, simultaneously guaranteeing the function of the components.

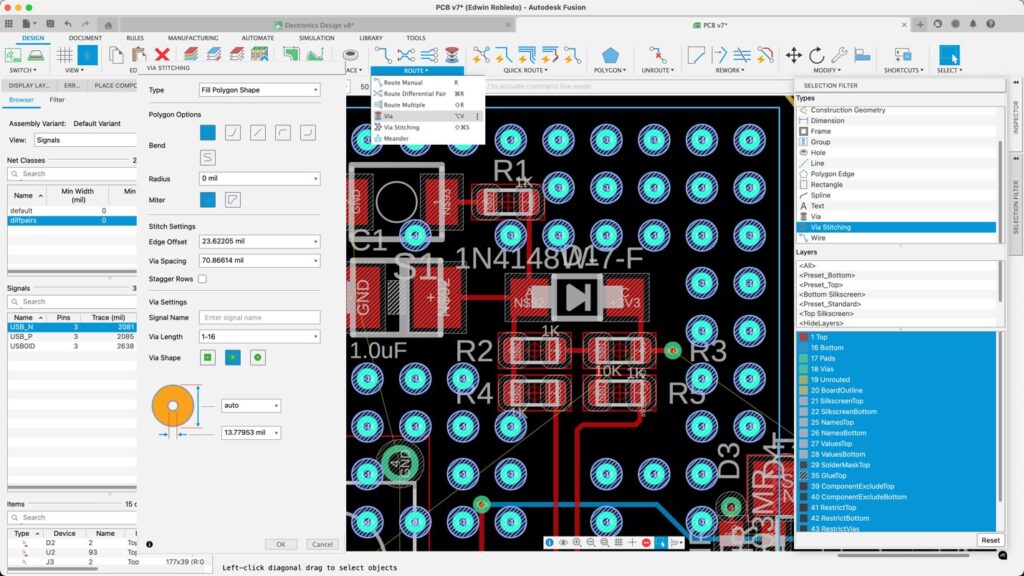

Another powerful tool in Fusion Electronics is via stitching, which enhances PCB design reliability by improving signal integrity, managing heat dissipation, and reducing electromagnetic interference (EMI).

Proper grounding is crucial when designing high-frequency PCBs, and via stitching features in Fusion electronics workspace make this process seamless. One of its key advantages is its intuitive handling. Notably, via stitch is integrated into the selection filter, making it easy to select, resize, or delete as needed.

The via stitching dialog box provides full control over via properties, allowing you to fine-tune parameters such as drill size and placement. Additionally, the design rule check (DRC) mask settings automatically calculate the necessary mask adjustments, ensuring compliance with your design constraints.

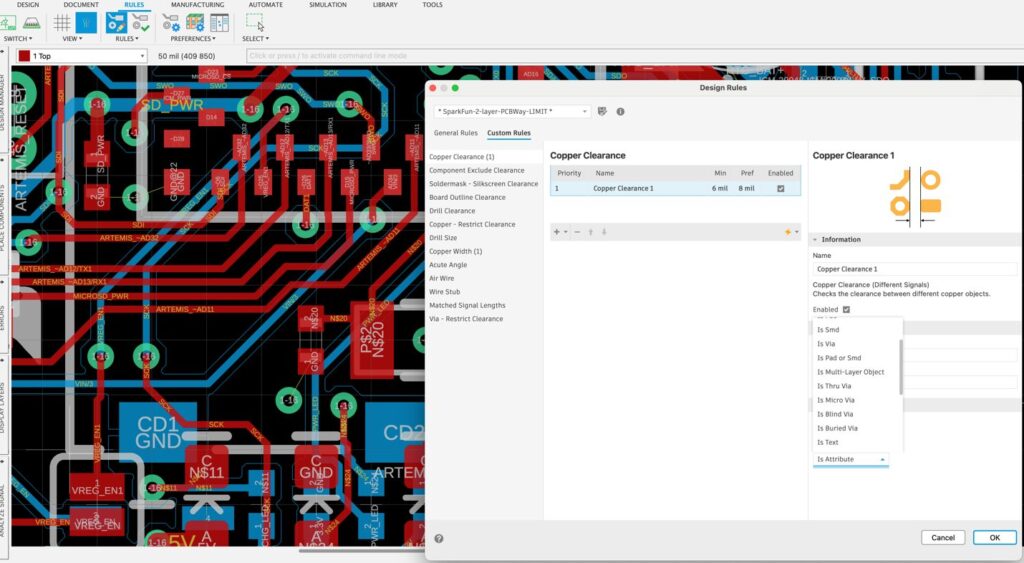

Fusion electronics redefines PCB design rules with a flexible, structured system that distinguishes design preferences—global PCB settings like layer stack-ups—from design rules, which enforce specific manufacturing constraints. This approach enables engineers to establish precise guidelines early in the design process, minimizing rework and enhancing workflow efficiency.

General rules define fundamental constraints such as trace widths and clearances, ensuring manufacturability while allowing for controlled overrides when necessary. Net classes provide targeted exceptions for specific circuit segments, such as wider traces for power rails, enhancing both performance and design integrity.

For even greater control, custom rules allow designers to apply constraints to specific layers, components, or nets—essential for managing the complexities of advanced PCB designs. Meanwhile, Live design rule checking (DRC) delivers real-time feedback, proactively detecting errors and ensuring compliance with industry standards. This intelligent rule-checking system streamlines the PCB design process, improving both accuracy and efficiency.

When mechanical and electronics engineers don’t work in sync, it can lead to costly mistakes—like discovering too late that a circuit board doesn’t fit the enclosure. Fixing these issues after the fact can mean wasted time, blown budgets, and frustrating delays. A connected workflow lets teams quickly adapt board outlines, check for interferences, and make real-time changes before it’s too late. Without a realistic 3D model, you’re designing in the dark, risking expensive rework and missed deadlines. When teams collaborate seamlessly, they save time, money, and headaches—getting great products to market faster. This is where Fusion truly shines.

Fusion electronics brings electronics and mechanical design together in one solution.

Fusion electronics is more than just software; it’s a solution for designers like you who demand performance, precision, and ease of use. It’s the smarter choice for consumer product seamlessly integrating PCB design, mechanical CAD, and simulation in a single platform. Furthermore, Fusion’s collaboration tools provide a centralized platform for managing design iterations and feedback from multiple stakeholders.

Whether you need cutting-edge features like QuickTune, via stitching or complex design rules due to design complexity and fabrication restrictions, Fusion Electronics equips you with everything you need to bring your ideas to life.

If you’re serious about taking your PCB design to the next level, try Autodesk Fusion Electronics. Trust me, you’ll wonder how you ever managed without it.

By clicking subscribe, I agree to receive the Fusion newsletter and acknowledge the Autodesk Privacy Statement.

Success!

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.