& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

11 min read

So, you got that circuit on paper as a schematic design in Autodesk EAGLE, but now comes the real challenge. How are you going to translate all of that electrical theory into an actual physical design? These days engineers do it all, from schematic to PCB layout, and there’s no handing it off down the line for someone else to finish it up, it’s all about you. While this can present you with a new set of challenges, the PCB layout is probably one of the most exciting and rewarding parts of PCB design. It’s like a giant puzzle just waiting to be solved with some original thinking and creativity. Where do you start with all of this? You’ll need to place all of your components first.

There are a few things you’ll want to keep in the back of your head while you go about transforming your schematic into a physical board layout, including:

Many engineers see the PCB layout process as more of an artform. If you give your schematic to a hundred different engineers, then chances are you’ll get a hundred different board layouts back all with their unique characteristics. Unlike a schematic design, which is all grounded in the finality of mathematics, your PCB layout is a bit more fluid and flexible.

People can get pretty creative with just some mere traces and vias. (Image source)

Because of this, you have to remember one thing when doing your PCB layout – there’s no right or wrong way to do it. How you choose to place your components and complete your routing is all a unique representation of your design perspective. For some, this might be a bit overwhelming at first, which is why we’re going to stick with a very simple design in this blog. We’ve only got a handful of components to place, so you can take your time to place, replace, and probably do it all over again.

Just get comfortable with the whole process.

At the end of the day, you are likely designing a PCB to have it made physically by your manufacturer. Because of this, you need to keep several considerations in the back of your mind as you go about designing. The first is component orientation. Whenever you place like-minded components on your board, like a set of resistors or LEDs, you need to make sure they’re always facing the same direction. Why? This will make your board much easier to install, test, and inspect by your manufacturer.

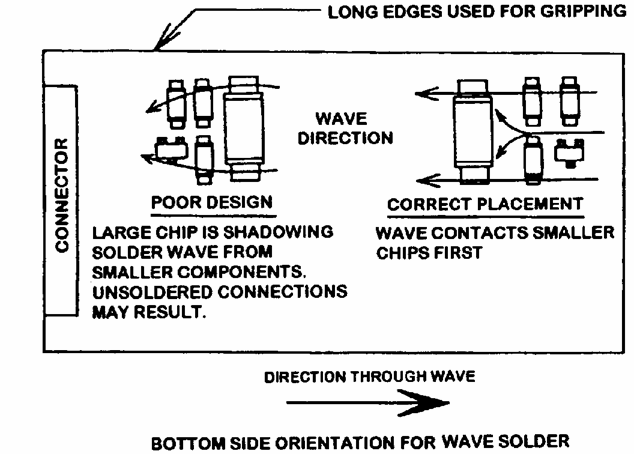

The second point to consider is how you are placing your components in relation to each other. When your completed board gets handed off to your manufacturer, they’re going to send it through a soldering oven to connect all of the parts to your bare circuit board. If you have taller components that are blocking smaller ones, then chances are you’ll likely get a board back with poorly connected solder joints. When placing components, always be mindful of their size not just in your two-dimensional space, but also their height and width. For a comprehensive list of part placement tips, check out this blog.

Be sure to place smaller components in front of larger ones for a reliable soldering process. (Image source)

It goes without saying that many beginner designers make the mistake of cramming their components too close together on their first layout only to run out of space when it’s time to start routing. This happens most commonly with integrated circuits which have lots of pins that need to be connected all over your board. If you don’t give this one component enough room to breathe, then you’ll likely run out of space and will have to start your layout over again from scratch. When placing components, always be thinking about how you’ll route them, and leave enough room between parts to make that process easy.

While your component placement and routing processes are filled with endless opportunities for creativity, we think it’s good to start with a structured process in mind. This isn’t meant to stifle your creativity, but to simply provide a foundation with which your creativity can grow. Once you know the limits of the walls and where you’re going, then you can be free to design as you please. The process that we’ll be using to complete the component placement process includes:

That’s all the details you need to know to get started. Let’s jump into some practical PCB layout strategies.

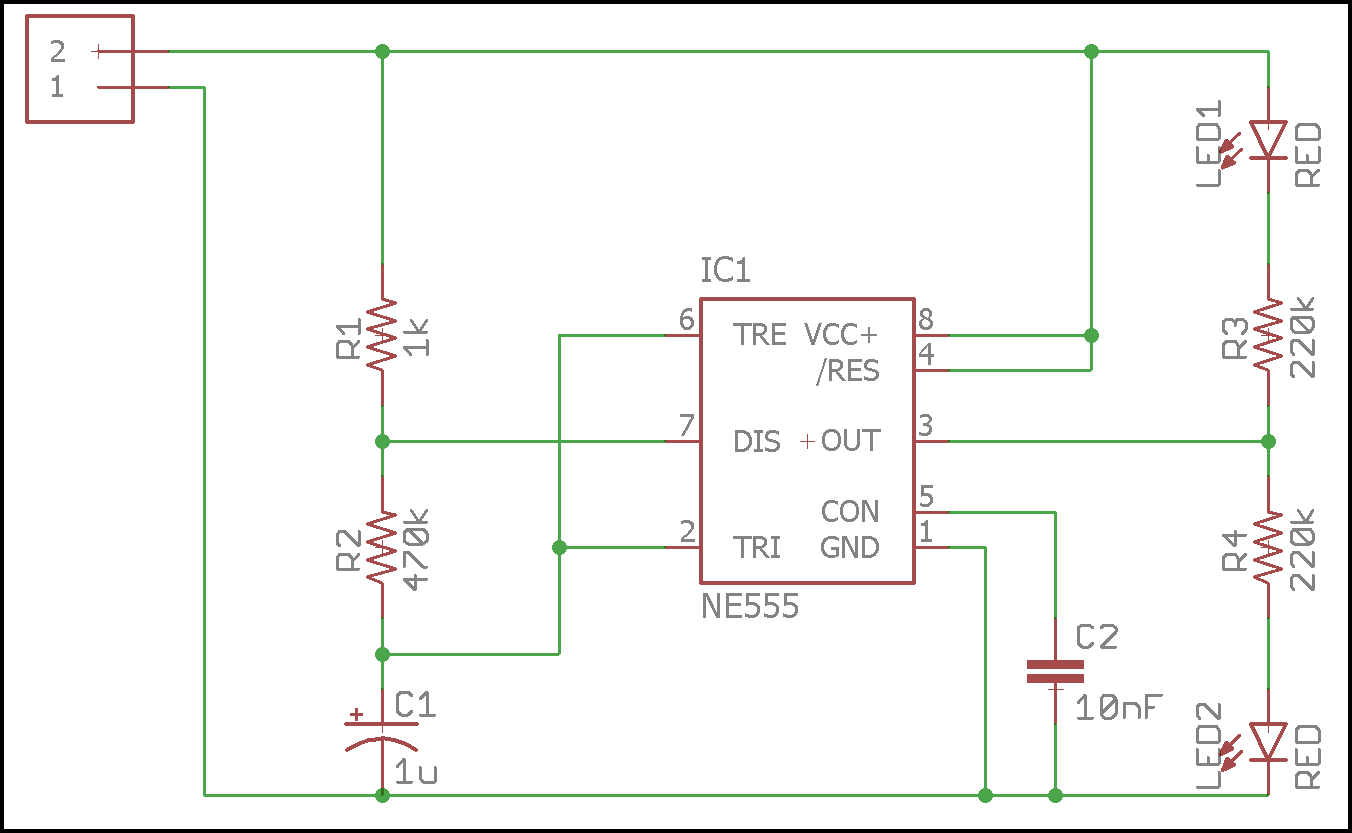

If you’ve been following along in our Schematic Basics Series, then you should have a complete schematic that looks like ours below.

Our complete LED Flasher schematic that we’ll be turning into a PCB layout.

But if this is your first time here then be sure to read through Schematic Basics Part 1, Part 2, and Part 3 to get yourself up to speed. To convert your schematic to a PCB layout, do this:

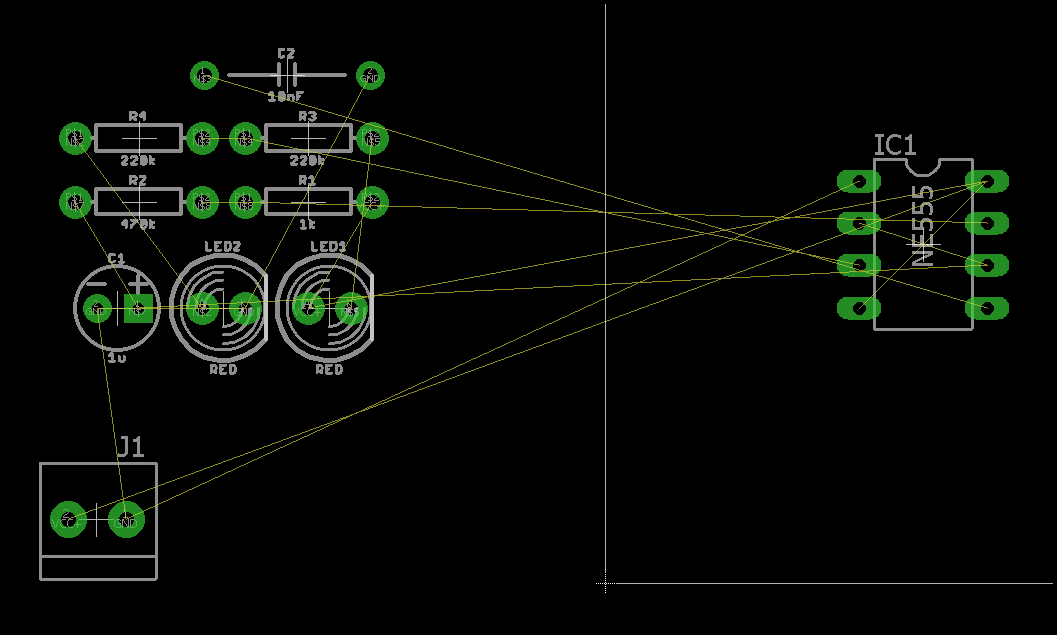

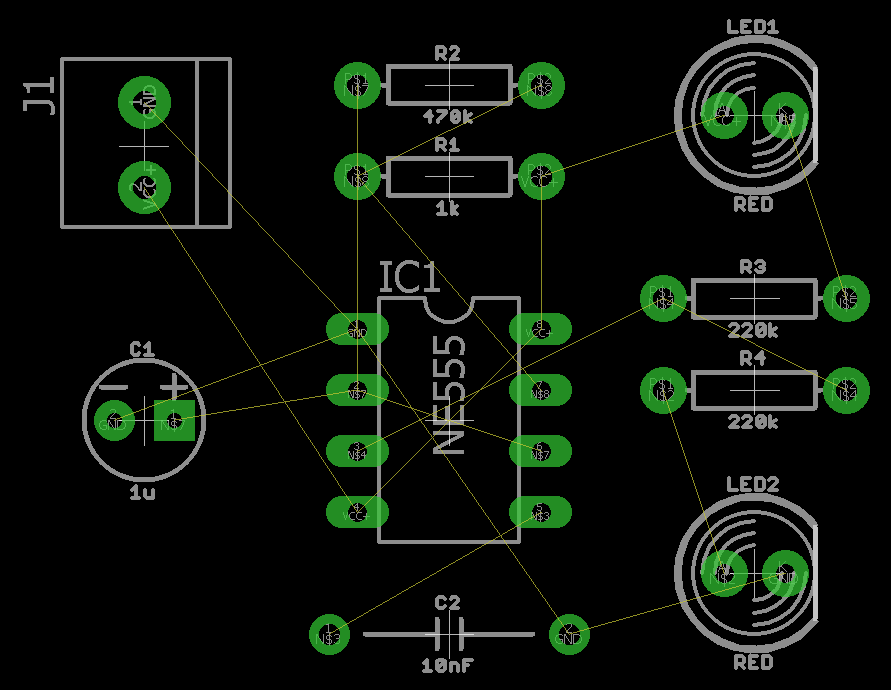

That’s it! You should now have a second Autodesk EAGLE window open that looks similar to ours below.

When you turn your schematic into a PCB layout file, you’ll get a new window that looks like this.

This is your blank PCB layout canvas where you will start your PCB design journey. Let’s take a moment to talk about what you see in case this is entirely new to you. Here are a few things to make a note of:

Now, let’s start moving and rotating your parts within the board space.

Ok, this is where we need to start staying nimble with the directions we provide. You’ve got your blank board layout, and how you choose to place your components is ultimately up to you. In a typical PCB component placement process, most engineers will go about placing all of their edge components first, things like USB ports, power jacks, headers, etc… These parts are stuck where they are and are determined by the mechanical enclosure that the board is going to be placed inside.

After the edge components, an engineer will then typically go about placing the largest components. Things like an integrated circuit with a large number of pins will have a huge effect on what components need to be placed around it. Our example design just so happens to include an IC, and you can use this big part as the first one you place. Here’s how:

We’ve got our IC placed in the bottom left corner of our board, ready for more.

Now that you’ve got the biggest part on your layout placed, which will help a ton when placing all of your other components. The rest of the placement process is all up to you! Still not sure where to start? Here are some tips to keep in mind:

Your goal is to place all of your parts in a way that minimizes the length and cross-crossing of airwire connections between your components. Keep compatible parts together, and always remember that you can route on multiple layers, so some crisscrossing of airwires won’t kill your design.

As you continue to adjust the placement of your parts, your airwires will likely need to be recalculated. Whenever you place a new part or rotate an existing one, be sure to select the Ratsnest ![]() tool on the left-hand side of your interface to redraw all of your airwires. This tool will give you a real-time update on how your placement decisions are affecting your airwire connections.

tool on the left-hand side of your interface to redraw all of your airwires. This tool will give you a real-time update on how your placement decisions are affecting your airwire connections.

All of those green circles and white outlines are part of the physical package for each of your parts, and they’ll need some room for assembly. If you end up overlapping those green circles, which are going to be exposed copper on your physical board, then you’ll get an unpleasant short circuit. Be sure to always leave room between components at all times.

The component placement process is a puzzle just waiting to be solved with your creative efforts. Remember, there is no right or wrong way to place your parts, just varying shades of optimization that you can discover. Take your time, and enjoy this process as much as possible. Below you’ll see how we decided to place our parts, but if it looks nothing like yours, then don’t sweat it. That’s what makes your design unique.

Does your part placement look like ours? Hopefully not, design it your way!

Note: Sometimes you might want to move a bunch of components at once. Rather than doing this individually, you can group parts and then use the move tool, here’s how:

Alright, by this point you’ve got all of your components placed. Did you find it creative, or maybe kind of awkward the first time around? Keep doing it again and again until you get into a component placement flow; then you’ll understand the magic. At this point, all of the hard work is done, great job! Let’s now finish up by defining the dimensions of your board layout with these steps:

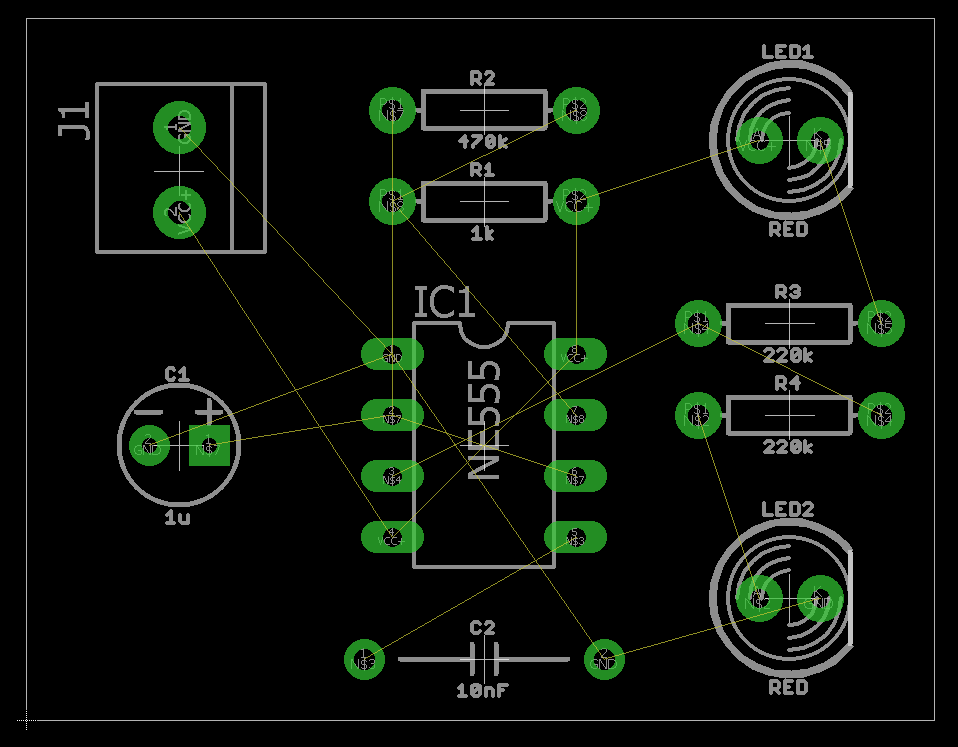

Once complete, you should have a much smaller PCB layout outline that nestles all of your components together in an efficient and compact package like the one we have below:

We’ve shrunk our PCB layout outline to nestle all of our parts together.

Way to go, you did it! You have now successfully placed all of the components on your very first PCB layout. There’s an old saying that goes like this – PCB layout is 90% placement and 10% routing. This is still just as true today. How you decided to place your components will ultimately determine how easy your routing job will be in the future. So did you make sure all of your airwires were as short as possible? If so, then you can expect the last 10% of your PCB layout process to be a breeze.

Chances are you might want to take a stab at your component placement process a few times just to see what kind of different results you get. The more you practice, the more you’ll start to notice the small details that can make your layout better each time. Don’t be afraid to experiment! This part of the puzzle is all about the art of engineering. Enjoy the creative endeavor, and we’re looking forward to seeing you again in our PCB Layout Basics Series. Here’s what’s up next:

Making your first PCB layout in the free version of Autodesk EAGLE is just the tip of the iceberg! Get the full experience today by subscribing to Autodesk EAGLE.

By clicking subscribe, I agree to receive the Fusion newsletter and acknowledge the Autodesk Privacy Statement.

Success!

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.