For Photocentric, 3D printing isn’t just for prototyping or niche applications. In line with Industry 4.0, the UK-based company’s goal is to bring it to mass manufacturing. To achieve this, they develop their own resin materials and design and manufacture a line of 3D printers that can deliver a vast array of parts and products for industrial applications.

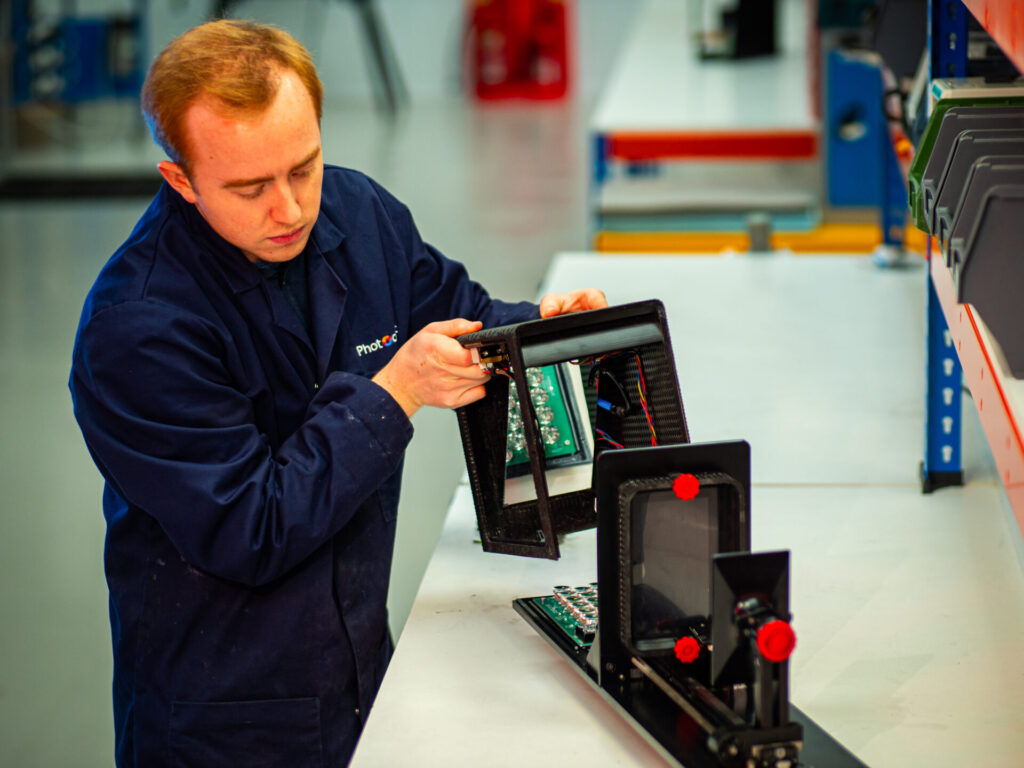

Photocentric’s flagship products include the LC Titan, LC Nano, and JENI. LC Titan is the largest LCD 3D printer in the world. It has a 32-inch, 8K screen inside and a 1.2-meter print height. With LC Titan, customers from a variety of industries—from automotive to aerospace and even entertainment—can print large and accurate products with high definition. JENI is the company’s vision for the future of 3D printing. It’s an automated system that combines multiple Nano machines into one unit capable of automating between printers, washing units, and curing units.

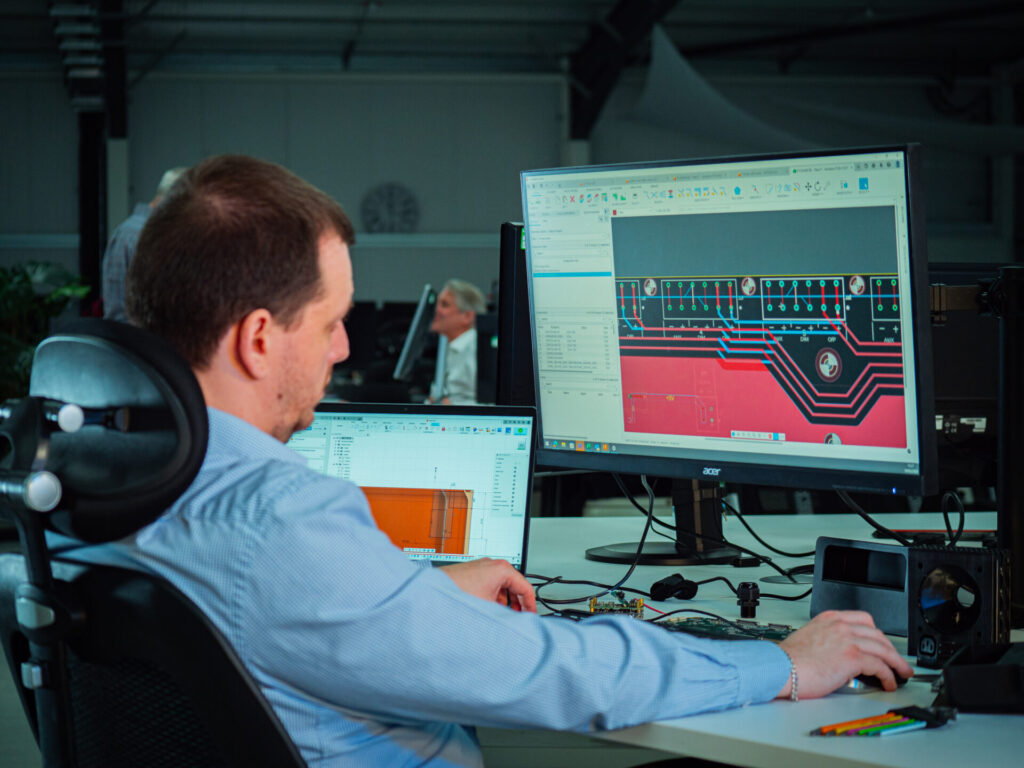

With Autodesk Fusion, Photocentric can collaborate easily and quickly to speed up their workflow. Generative design is used to evaluate potential design options, and automated drawing helps them generate many complex drawings that are often needed in a very short space of time.

“We develop all of our products in Fusion,” says Ed Barlow, Head of Engineering, Photocentric. “It’s an incredibly powerful tool that allows us to do all aspects of the design all in one package. Fusion is the backbone of our design process.”

“We moved from another platform to Fusion. The reason is because we wanted to have everything in one place.”

—Hanifeh Zarezadeh, 3D Product Manager, Photocentric

Designing the revolutionary LC Nano 3D printer

LC Nano is the fastest LCD 3D printer in the world with Photocentric’s patented Blow-Peel technology that enables very fast layers. One of the unique design features of LC Nano is a 3D-printed housing. “The 3D-printed housing is only possible because we used Fusion’s Product Design Extension to build in lattices into it, which help it print really, really straight and rigid,” says Josh Moody, Senior R&D Design Engineer, Photocentric.

For LC Nano, the Photocentric team also faced complex design challenges with the electronics, optics, and hardware all in one design. The LED array is at a 90-degree angle to the screen and a mirror is used to reflect the light up. It was important to determine the correct placement of the LED and ensure the light hit the screen in the right spot. In the mechanical workspace in Fusion, they created sketches and translated it into the electrical workspace so LEDs could be positioned accurately on the PCB.

“Advanced tools like the Signal Integrity Extension give us the ability to design right the first time rather than iterating over and over again with the mistakes that we make,” Barlow says. “In a machine like this where the LEDs are crucial to the machine’s operation, keeping everything in the same design tool has saved us hundreds of hours of design work. It gives us a huge boost to productivity.”

“Digital manufacturing is an industry that is moving so fast, and we can move so fast with Fusion as well,” Zarezadeh adds.