Learn how to assign plastic rules to components in your design and how you can automatically assign them to various solid features using the Fusion 360 Product Design Extension.

The Fusion 360 Product Design Extension is a set of advanced 3D design and modeling tools that enable an automated approach to creating complex product designs.

Let’s walk through how to assign and use plastic rules in your designs with the extension.

Plastic Rules in Fusion 360 Overview

The Assign Plastic Rule command lets you assign a specific plastic rule to components in your design.

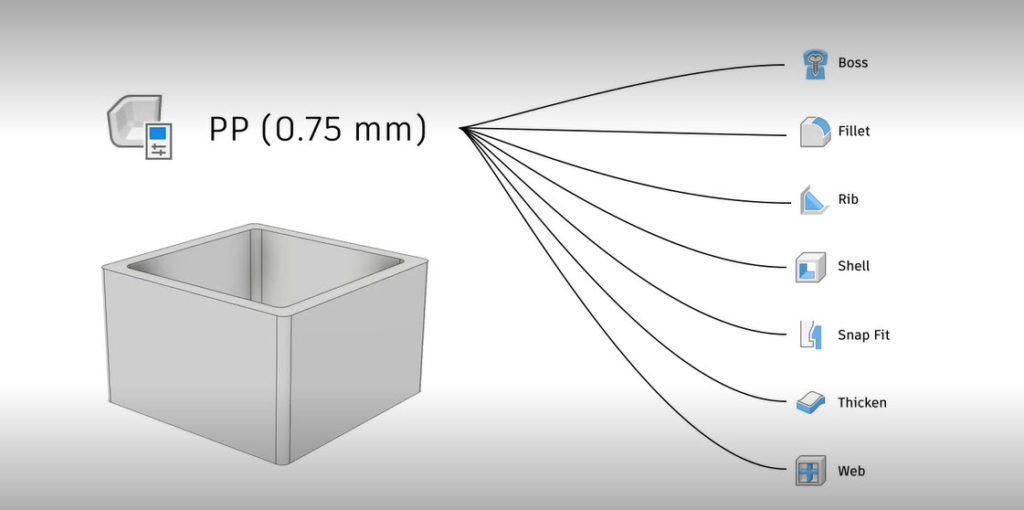

The plastic rule automatically controls certain properties of features within that component. These include physical material, thickness, and radii, using automatically generated parameters and physical properties.

With this tool, you can quickly apply plastic material properties to any components in your design. Also, due to the parametric nature, you can edit these values at any time. And then have those changes propagate to any components with the respective material rule assigned to them.

As a best practice, you must assign the plastic rule prior to using subsequent parametric features such as Shell or Thicken to ensure those features inherit settings and parameters from the plastic rule.

How to assign plastic rules in Fusion 360

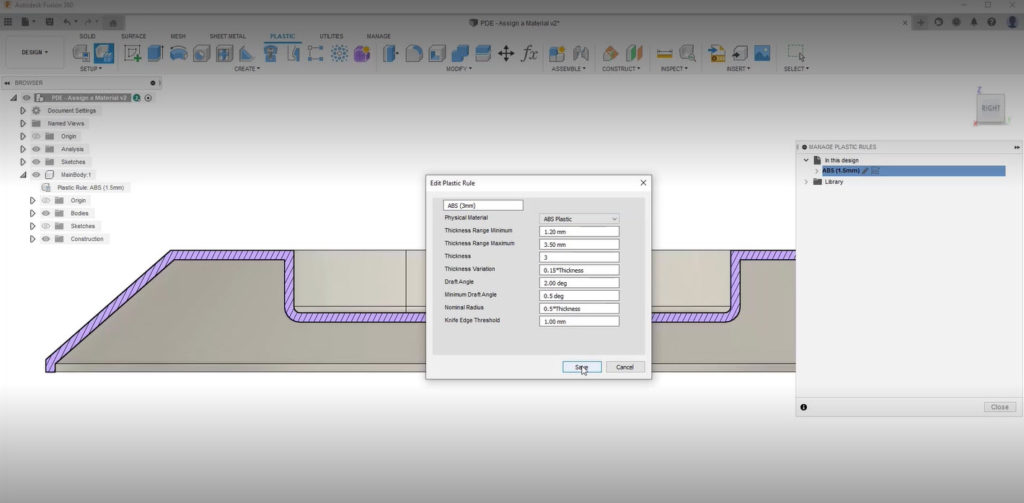

To start, you’ll need to access the command in the Design workspace. Then switch to the Plastic tab and locate it on the toolbar.

When the Assign Plastic Rule dialog displays, you can select a component in the browser or the canvas, and see the displayed list of plastic rules. You can then expand each rule to see its specific settings.

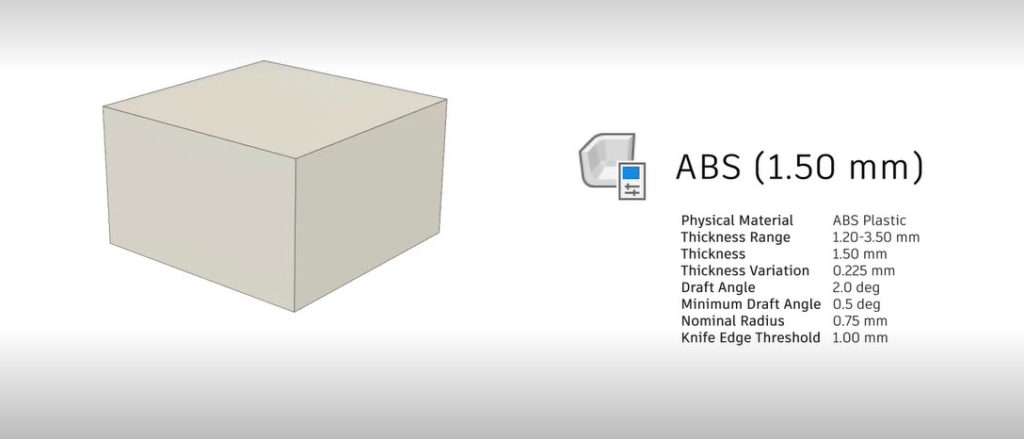

These fall into three categories:

Physical Material

- Applied to the component

- Affects physical/mass properties based on plastic material

Physical Values

- Thickness, Draft Angle, and Nominal Radius, which are referenced as parameters and used by modeling commands such as Extrude, Rib, Web, Boss, Snap Fit, Emboss, Thicken, Shell, Draft

Design Advice Values

- Thickness range, thickness variation, minimum draft angle, knife edge threshold

- Used by design advice to identify manufacturability concerns based on best practices for plastic injection molding, and provide recommendations to address them.

Next, select a Plastic Rule, then click OK. The plastic rule is then assigned to the component and is displayed in the browser. Here you can see the name of the rule as well as its settings.

Physical material and appearance

If you open the Physical Material dialog, you’ll see the material also applies at a physical level with the appropriate appearance and physical properties. If you ever change the plastic rule for a component, these properties update accordingly.

You can only assign plastic rules at the component level — not to individual bodies. Thus, all the bodies that sit within a component will inherit that component’s particular physical material properties and appearance as defined by the plastic rule.

Plastic rule parameters in Fusion 360

When assigning materials, you’ll find automatically populated parameters in the Parameters dialog. In the Model section, you’ll see parameter values that are respective to the materials assigned.

Now every time you perform commands such as Shell, Thicken, Draft, or Fillet, these parametric values will be automatically assigned.

If you decide to change any of the material’s values, you’ll only need to change one value to have these propagate against all instances with that same parameter reference.

Ready to expand your 3D design capabilities in Fusion 360? Get started with the Product Design Extension today.