Learn why undergoing digital transformation in manufacturing is more vital than ever and how Autodesk Fusion can support.

As the manufacturing sector undergoes significant transformation, the imperative for digital integration has never been more apparent. Autodesk Fusion represents a paradigm shift in how manufacturers approach the digital age, offering comprehensive tools and strategies that ensure businesses are prepared and leading in their fields. This shift is not just about adopting new technologies; it’s about weaving digital processes into the very fabric of the business, enhancing connectivity across the production chain from design to delivery.

Fusion enables manufacturers to leverage real-time data and automation, transforming challenges into opportunities and driving efficiency at every turn. This proactive adaptation to digital tools is essential for manufacturers who want to survive and excel in an increasingly competitive and technologically advanced marketplace.

Strategic adoption of digital tools

Autodesk Fusion provides an all-encompassing interface that bridges various stages of product development. This facilitates a fluid transition between design, engineering, and production, enhancing efficiency and reducing time to market.

Implementing the full Fusion platform involves a strategic blend of its core components, each tailored to enhance digital workflows: Fusion for seamless CAD/CAM/CAE operations, Fusion Manage for robust lifecycle management, and Fusion Operations for real-time insights into shop floor activities. These tools are complemented by Autodesk Platform Services (APS), extensive APIs, professional-grade extensions, and strategic partnerships, creating a rich digital ecosystem that supports every manufacturing phase.

Fusion Manage elevates project oversight, enabling manufacturers to maintain stringent control over every project phase, from inception through to market delivery. This ensures projects meet set timelines, budgets, and quality standards.

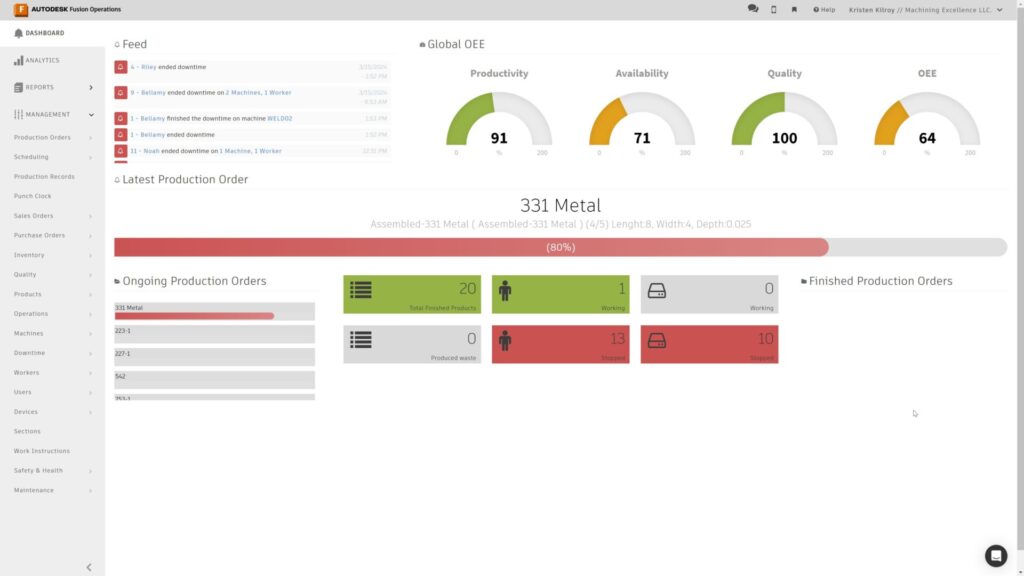

Fusion Operations delivers critical data from the manufacturing floor directly to decision-makers, allowing for agile responses to operational challenges and enabling proactive management of production processes.

Extending capabilities through Autodesk Platform Services (APS) allows manufacturers to customize their digital landscape, ensuring tools and workflows are precisely aligned with specific needs. Whether through developing bespoke applications or integrating existing systems, these capabilities ensure manufacturers can adapt to unique challenges.

Enhancing operations with extensions and strategic partnerships introduces cutting-edge technology and external expertise into the Fusion platform. These relationships foster innovation and ensure that Fusion remains at the forefront of technological advancements.

Anticipating future industry trends

Rapid technological advancements are shaping the digital future of manufacturing. Key trends on the horizon include the integration of AI and automation, which promise to revolutionize production planning and responsiveness. In sectors like semiconductor manufacturing, where rapid scaling is becoming increasingly common due to legislative initiatives like the Chips Act in the United States, the ability to dynamically adjust production in response to market demands is crucial.

Manufacturers that leverage data will gain a competitive advantage. They will be capable of optimizing production in real time and achieving unprecedented operational efficiency. Autodesk Fusion is instrumental in this regard, providing the tools necessary to harness the power of data for strategic decision-making.

The imperative for continuous innovation

The landscape of manufacturing is rapidly evolving, driven by digital transformation. To maintain competitiveness, manufacturers must adapt to current technologies and, continuously innovate and anticipate future changes.

This approach mirrors the Kaizen philosophy pioneered by Toyota, which emphasizes continual improvement in operations. A concept we, as manufacturers, are always looking to use. By integrating Kaizen principles into their digital strategies, manufacturers can systematically enhance processes and embrace incremental advancements, ensuring they keep pace with technological evolution and lead it. Fusion facilitates this ongoing evolution, offering a scalable, integrated platform that supports the expansion and adaptation of manufacturing capabilities.

Manufacturers who embrace this digital shift position themselves as industry leaders, ready to tackle upcoming challenges and seize new opportunities. The journey towards digital transformation is multifaceted and ongoing. Still, with the right strategy and tools, it offers substantial rewards, propelling businesses toward a future where they survive and thrive.