This article is based on a Raconteur report about the democratization of product design. You can download your copy of the full report here.

What are the design process steps?

A successful design process encompasses collaboration, innovation, and matching strength with strength. In-house design teams that adopt “intelligent naivety” as their guiding principle are seeing immediate dividends for their approach.

What is the design process?

The term “design process” conjures images of artists and engineers checking off their tasks and comparing notes as they churn through the secret recipe for innovation. Many new designers assume that this recipe exists, buried deep within the executive offices of only the finest design firms. The reality, however, is that the best designers in the world do the exact opposite of this. If anything, the secret sauce for top-notch design is more of an anti-recipe. In short, it’s a set of practices and philosophies that disrupt routine and inject outside thinking.

The ingredients in this anti-recipe don’t need to be overly complex. As Darren John, owner of Absolutely Studio, explains, “It can be as simple as a change of setting or pairing employees from different disciplines or sectors.” He adds, “Being able to curate the right individuals to generate ideas together can be rocket fuel for the curiosity needed to boot down the doors to possibility.”

These types of small disruptive adjustments work to guide designers along a path of “intelligent naivety.” This is a way to approach design problems from the perspective of an outsider without any preconceptions. From here, innovation, creativity, and spontaneity flourishes.

The seven steps to the design process

Utilizing the design proess steps in order adds structure and breaks down the design process into more manageable pieces. Below are the seven steps of the design process:

- Identifying the problem

- Researching it in-depth

- Ideating possible solutions

- Evaluating and selecting a promising solution

- Creating a prototype

- Testing and troubleshooting

- Making improvements to and releasing the final product

General Product Design Processes: Corporate In-House Design

Larger corporations that maintain a dedicated team of staff designers may have the toughest time navigating the landscape of fresh ideas. By definition, outside thinking is difficult to come by. The natural instinct for control and ownership often burns down any bridges that lead off the corporate island. In addition, an all-too-common culture of complacency, fueled by a lack of risk and reward, generally fails at incubating exceptional design direction. To overcome these difficulties, companies need to explicitly embrace a dynamic work environment. They also need to invite the outside world into the process of innovation.

A successful product design process at LEGO

A shining example of a successful product design environment within a large corporation is the LEGO company. Its products include LEGO sets designed for forty different “themes” over the span of nearly a century. It also continues to innovate and explore the boundaries of play as the world around it changes. The LEGO work environment is directly responsible for this.

Collaboration at LEGO is encouraged. Desks are physically close to each other. Additionally, design teams each share a common build table fully outfitted with all available bricks. While the projects themselves are highly confidential, leadership encourages team members to talk among themselves. This typically involves chatting about all the latest updates and new ventures. They are also free to move between projects and focus on a theme that inspires them.

In order to connect to the outside world, children get invitations to the design studio. Here they’ll test out the latest products and even offer suggestions. Designers also receive invitations to annual innovation week where they’re given a platform to pitch their own product ideas. All of these seemingly simple characteristics come together to create a large impact on corporate culture. This, in turn, has kept the LEGO brand fresh and innovative.

Design to Hire

A large segment of the product design process falls into the category of “on-demand.” This is where a company hires a specialized firm to tackle its latest project. One such firm – Here Design – is a multidisciplinary team of writers, artists, and thinkers that breathes life into some of the most notable brands. They subscribe to the ethos of intelligent naivety, ensuring that they explore the entire space of design potential. Tess Wicksteed, the strategy partner at Here Design, explains, “Intelligent naivety is a good description of the de Bono type problem-solving at the heart of most projects. [Designers must] think like a child [and ask] why things are done a certain way. We typically start by asking very, very practical questions and then ladder up to very high concept questions.”

The “anti-recipe” to a successful design process at Here Design

As part of this journey, Here follows the anti-recipe to the structured routine. Implementing a work environment that is anything but ordinary. With the recent shift toward virtual and remote work, it was necessary to rethink the purpose of the physical design studio. This shift arose by recognizing that working from home can strand the designer on a digital island. Often fraught with video calls, emails, and texts — Here realized that the studio should act as a counterbalance, transformed into a space for digital decompression. Case in point, emails replace paper and pen. In-person conversations replace video calls, and a group of creative colleagues replaces the personal computer. Every physical aspect of the studio is a design element supporting the creation of a spontaneous and creative workplace.

To go even further, they decided to open the studio up to clients. Enabling them to join in the process of collaboration during key design stages. The result of this shift in how they use their offices is a boon for the quality of work they deliver. This extends to Here’s clients and a boost in the satisfaction earned by their designers.

Design process on the fly

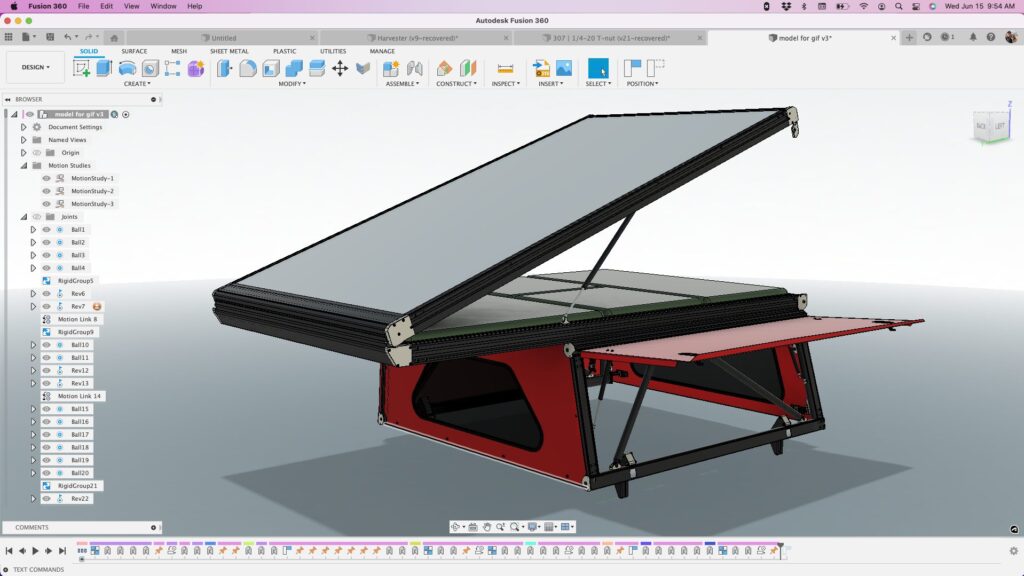

If in-house corporate design and for-hire contract design sit on one end of the spectrum of product development strategies, then the Go Fast Campers (GFC) process stands firmly at the other. In 2017, GFC set out to make the best platform campers and rooftop tents on the market. They also committed as one of their core philosophies to manufacture everything in-house, entirely in the USA. To do this while creating a cost-competitive product, a very unique design and build team was required. In addition, an equally unusual work environment was a necessity.

How “intelligent naivety” manifests itself at Go Fast Campers

At GFC, “intelligent naivety” manifests itself in their willful uphill battle against the mainstream manufacturing truisms. This includes using cheap labor, outsourcing when possible, and cost reduction at the beginning of the design process. Instead, GFC manages labor costs by entrusting a smaller team with large responsibilities. While outsourcing may be simpler at the onset, GFC believes that upskilling in-house talent is the way to go. It allows them to control their destiny when challenges inevitably arise in the long term. They’ve invested years of time and budget into developing their own manufacturing facility and techniques. This includes a concerted focus on using a variety of robots for high-precision automation.

“By using automation, we’re able to create a better, more empowering work environment for our employees; and because we strive to create a flat company structure, profits are distributed more evenly too.”

-Go Fast Campers website

After the team completes an initial design in CAD, it gets quickly vetted by the machining, assembly, and quality teams. The team can then discover any manufacturability issues, tune tolerance stack-ups and make any number of minor tweaks and improvements in a rapid prototype cycle. By having a highly-skilled, tight-knit team working on a product they are fully invested in, GFC has been able to deliver some of the best campers on the market. Ultimately reducing their lead time on a custom product to a mere 10 weeks.

Update your Product Design Process with Fusion 360

These three companies make at least one thing clear: No matter if your office is fully in-person, fully remote, or based on a hybrid, collaborative model, there’s always room for improvement with your design process.

Autodesk Fusion 360 enables collaboration across teams and offices. Once your team begins to embrace intelligent naivety, you’ll need the right software to get the most out of your design iterations. Cut down on your time to market and get the right people in the room right away with Fusion 360.

Learn more about how to remove barriers to breakthrough product innovation with Autodesk Fusion 360 here, and download your copy of the full report here.