This post is also available in: Italiano (Italian) Deutsch (German)

Learn how the ITERATE team uses Fusion 360 to help startups, SMEs, and others bring new products to market rapidly and successfully.

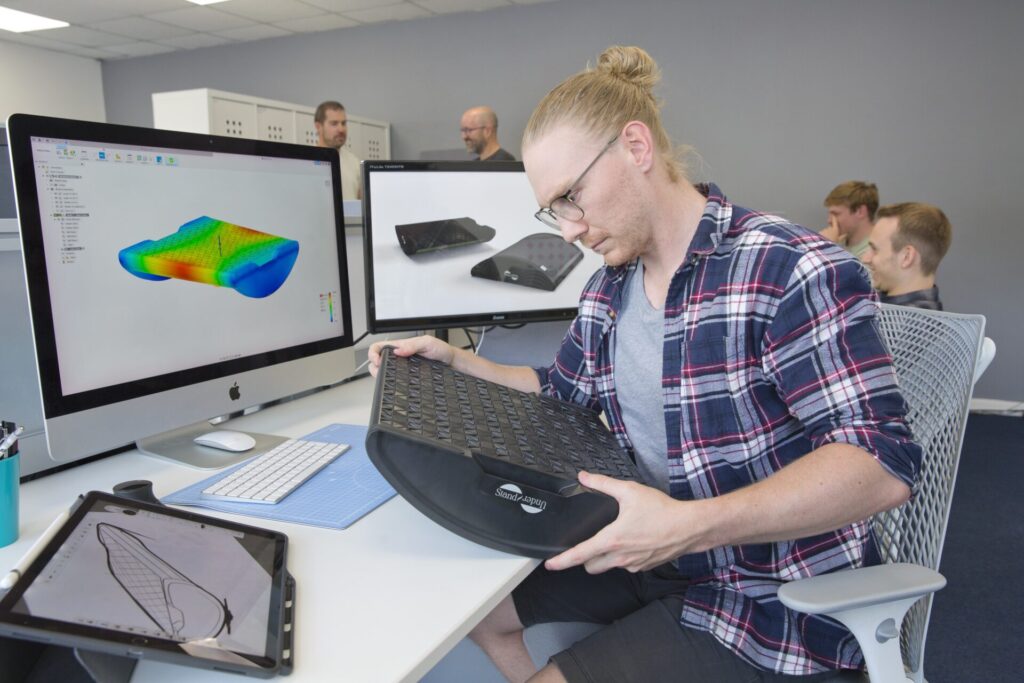

ITERATE Design and Innovation Ltd is a small, dedicated team of design engineers located in Chepstow, Wales. The company specializes in helping startups and other businesses turn ideas into actual finished, marketable products. To succeed in this mission, ITERATE practices what they call “purpose-driven” design and uses Autodesk Fusion 360 as their primary design and development tool.

Embracing purpose-driven design

ITERATE founder Gethin Roberts started the company eight years ago with the mission to help companies with big ideas and a lack of experience with the go-to-market process bring their ideas to life.

“We call it purpose-driven product design,” Roberts says. “We aspire to work on projects that will have a positive impact on the world. We know we can design widgets all day long. But we want to be intentional about delivering value through useful, sustainable products.”

When Roberts first started out in the product design field over a decade ago, the industry was primarily focused on emerging technologies like 3D printing. Today, he acknowledges that what really accelerates product development is spending a great deal of time focusing on process, specifically analyzing product concepts for manufacturability, market viability, and financial backing ahead of time.

“If these aspects haven’t been considered, you can waste a lot of time,” he says. “In my prior jobs, products would be developed before teams realized the design needed to be twice as large to be manufactured correctly or its key feature had already been patented. We really encourage our clients to think about all these factors before they even officially engage with us.”

Approachable, transparent design work

Companies that gravitate toward ITERATE’s purpose-driven approach include startups that may lack in-house design capabilities or are developing a product for the first time. They range from those who have an idea but no financial backing to those who are fully venture-backed and are ready to move from concept to finished design. Many of these companies tend to work in the tech, healthcare, and medical device sectors.

“No matter what they need, we work with them in a lean, efficient way to provide them with some form of design collateral,” Roberts says. “That may be concept designs or a prototype they can use to generate funding. We help them get the process started.”

Whatever process they end up facing, ITERATE prides itself on its accessibility, approachability, transparency, and open communication style.

Selecting the right product development tool

When Roberts founded ITERATE, choosing a design platform that aligned with these values was the company’s first challenge. Roberts was a Solidworks user throughout his university education and professional career. But the cost caused him to rethink this decision.

“Choosing Autodesk Fusion 360 is kind of a big part of our success,” he says. “At first, I wanted to get a Solidworks license. But I quickly realized, if we need a second design engineer, we’ll need another license. And that would be a real struggle.”

At this point, ITERATE tried out a range of cloud-based solutions. They eventually decided on Fusion 360 because of its overall affordability, flexibility, and the number of capabilities included in the single platform. In addition, Roberts notes that Fusion 360 is very intuitive for everyone — even those with minimal CAD experience.

“Fusion 360 has allowed us to be braver in our work,” Roberts says. “What I mean by that is, we could grow our design team and pitch new projects without any concern about where we would find more money for additional licenses. Without Fusion 360, growth would have been much riskier.”

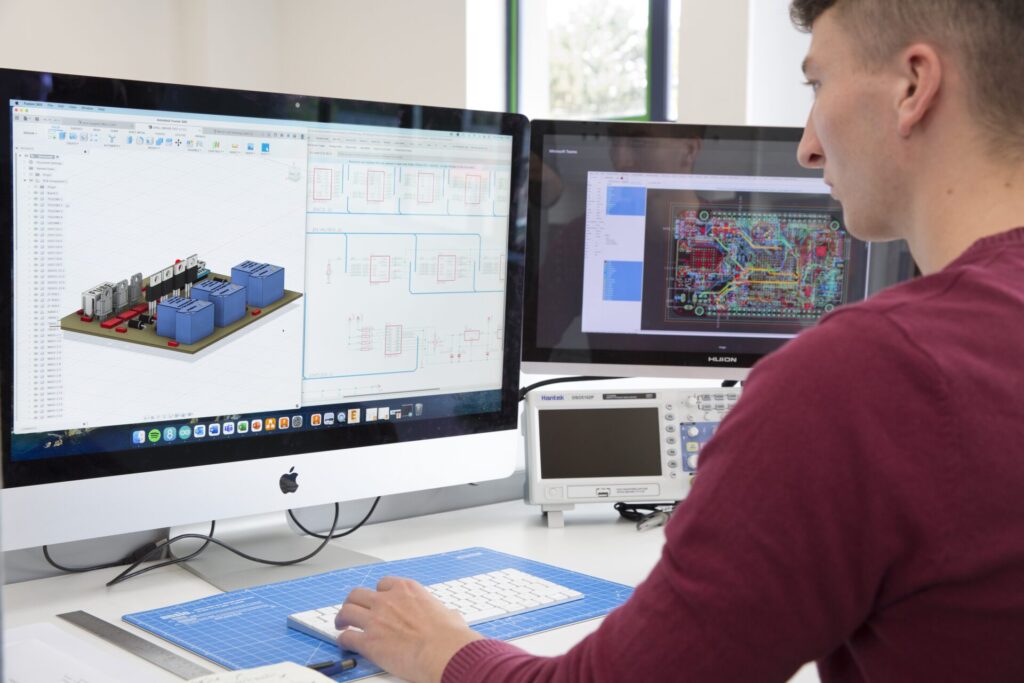

Much to his surprise and delight, Fusion 360 continues to expand its capabilities, from generative design to Moldflow to electronics.

“Fusion 360 is becoming a single CAD design hub for everything we would ever possibly need,” Roberts says. “When we decided to use it, we never anticipated that there would be so much continued investment in its development and that it would happen so quickly. Fusion 360 is basically a competitive differentiator for us at this point.”

Focusing on sustainability

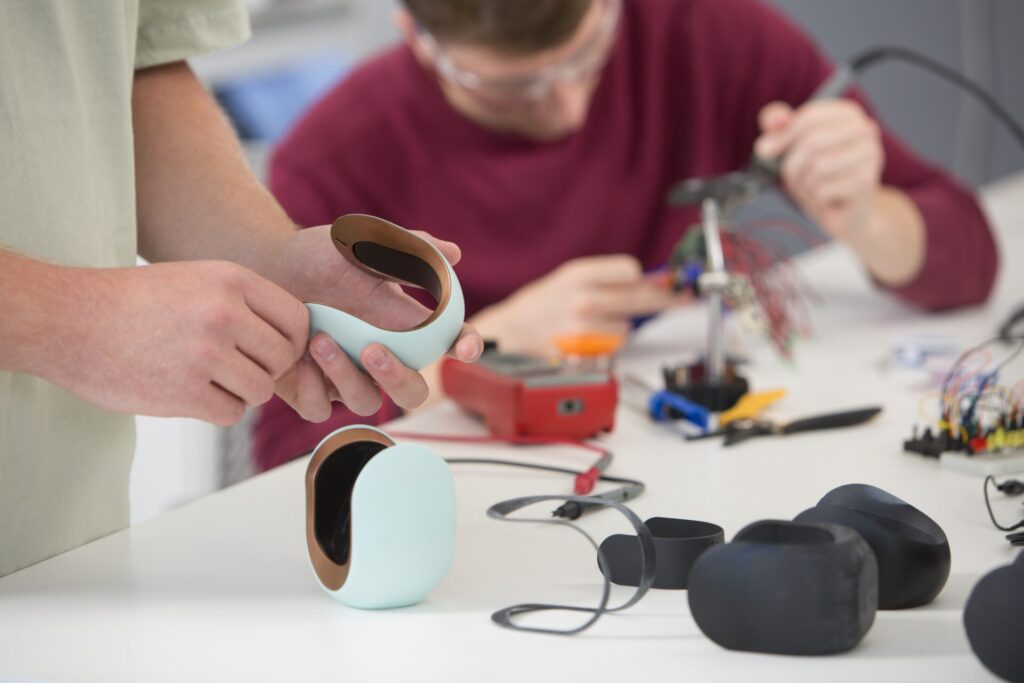

In addition to working with private clients, ITERATE develops its own product ideas. The first of these is the MOHONTO sustainable shower head, which recently won a European Product Design award.

“Our research showed that even if you have a multi-pattern shower head, you don’t use most of those patterns,” Roberts says. “You set it to the one you like and leave it there.”

The ITERATE team then aligned this idea with the two major drawbacks of most multi-pattern shower heads. One is the number of components involved, from chamber seals to springs and switches, which can run as high as 20 or 30. The other is the need for ultrasonic welding, which makes objects harder to recycle.

The MOHONTO shower head has three parts instead of 20 or 30. The head’s metal construction extends the product’s lifetime significantly, and the entire head is much more sustainable and easier to recycle.

“Using Fusion 360, we designed a very simple shower head with a machined aluminum head that is smaller and weighs less than most other shower heads. It can be outfitted with any number of 3D-printed faceplates that change the shower pattern.”

“You can print as many pattern face plates as you like, using a little tool to replace them as needed,” Roberts says. “We’re envisioning a smartphone app that lets users take a little survey to identify their ideal shower pattern and see it in a virtual environment. Then we could 3D-print it on demand.”

The key insight behind MOHONTO’s clever design speaks directly to how ITERATE starts with a complete picture of the market landscape before proceeding with the design process.

Building for the future

Fusion 360 also comes in handy during ITERATE’s government-backed consulting work with small businesses in Wales. This program incentivizes businesses across many industries to improve their products or generate new IP assets with help from the government.

“We can help [these businesses] identify the right material for a new product, find a market for a concept they have in mind, sketch ideas, or create 3D CAD models with Fusion 360,” Roberts says. “True to our values, we are often helping them think through the entire product design process to make it more efficient or use technologies they weren’t aware existed.”

Empowered by Fusion 360, ITERATE continues to grow steadily and expand, all with the goal of realizing Roberts’s vision of truly purpose-driven design.

“We have a responsibility as product designers to consider the environmental impact of our work,” he says. “As ITERATE continues to grow, we will have more opportunities to work on projects with a bigger reach and a potentially bigger impact on the world. That’s what I’m most excited about.”