This post is also available in: Français (French) Italiano (Italian) Deutsch (German) 日本語 (Japanese)

Data is a critical part of any manufacturing process. Learn how Autodesk Fusion industry cloud puts this first to help transform the way you work.

In the dynamic landscape of modern manufacturing, data is not just a resource. It’s the lifeblood that drives efficiency, quality, and competitive edge. Autodesk Fusion industry cloud epitomizes this philosophy, putting data front and center and transforming the way we think about manufacturing processes.

The impact of data in manufacturing cannot be overstated. Data is the cornerstone of modern manufacturing, from optimizing processes to enhancing quality control, from predictive maintenance to efficient supply chain management. Its role in cost reduction and real-time decision-making is pivotal, ensuring compliance and steering businesses toward success.

Autodesk Fusion industry cloud

Autodesk Fusion industry cloud is at the forefront of this revolution. As Raji stated, “Data is the make or break for Generative AI.” This powerful statement underlines data’s crucial role in unlocking our greatest ambition: making lives easier and unlocking true potential.

Imagine the frustration of recreating a stock part from scratch because you can’t find the original or committing to a delivery without knowing your production capacity. These are real challenges faced in the manufacturing world, often stemming from data that is disconnected.

Forrester’s report highlights a startling reality: on average, professionals use 45 different apps or services daily, leading to siloed data. This fragmentation is costly. Both in terms of time and money, with about 30% of working hours spent merely searching for data.

Autodesk Fusion industry cloud is not just another tool; it’s a paradigm shift in how we handle data. It’s about breaking down data into manageable bits, ensuring interoperability, and enabling seamless collaboration across different platforms so you can share your work between tools – ours and our competitors.

Yes, even that one competitor…works.

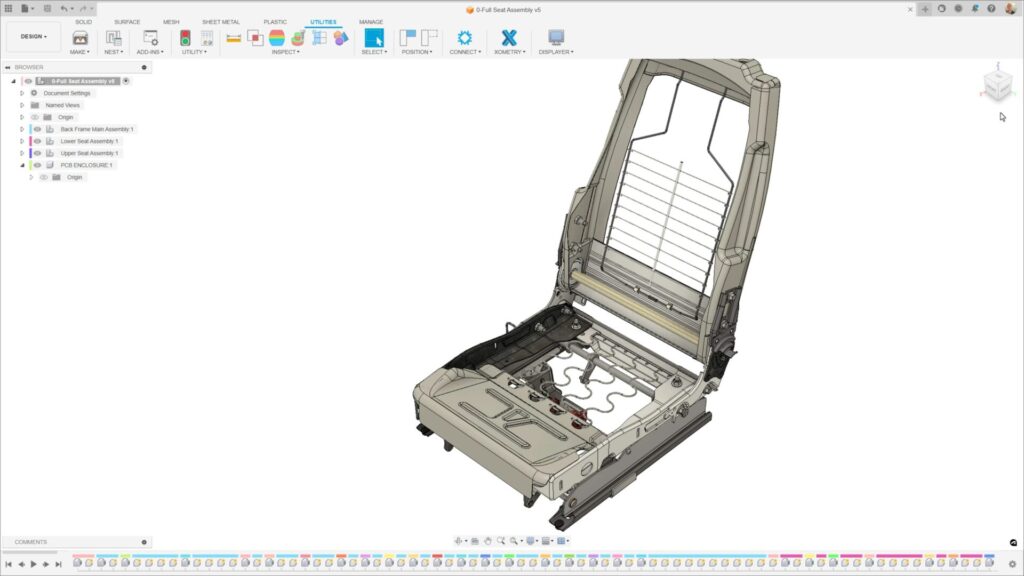

Autodesk Fusion’s cloud data model

The heart of Fusion’s approach lies in its cloud data model, which can represent all parts of CAD, CAM, PLM, and MES data. It’s a model that’s transparent, decoupled from logic, and highly modular, ensuring scalability and performance.

Consider a scenario where an Inventor user, managing data in Vault, collaborates seamlessly across a global team. With Fusion, changes synchronize in real-time. This ensures all team members, from analysts to marketers, access the most current data, enhancing productivity and decision-making.

This level of collaboration is crucial in today’s interconnected world. As 86% of manufacturing leaders indicate, better collaboration is not just a ‘nice-to-have’; it’s a fundamental necessity.

Autodesk Fusion is not stopping at collaboration. It’s pushing boundaries with cloud-enabled generative design, configurations, and the highly anticipated cloud-enabled bill of materials. This approach facilitates an unprecedented level of product development – faster, more efficient, and highly collaborative.

In partnership with Makersite, Fusion is also tackling pressing issues like reducing carbon impact and cost, allowing instant analysis of a design’s carbon footprint right at the early stages of the product lifecycle.

Autodesk Fusion industry cloud is more than a software solution; it’s a catalyst for unleashing full potential. It’s about moving from incremental growth to hypergrowth, optimizing products for better outcomes, and revolutionizing how products like adventure vehicles are designed and made, as seen with Rivian’s use of the Autodesk platform.

In summary, Autodesk Fusion industry cloud is redefining manufacturing with its data-centric approach. Addressing real-world challenges, enhancing collaboration, and driving innovation are not just changing how we work; they are shaping the future of manufacturing.