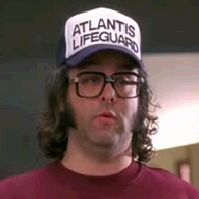

For many designers, there’s a disconnect between going from design to production and the in-between. Many of you might not yet have a purchasing department, you just switch from one trucker hat to another, the first one reads engineer, the other one reads purchasing. Yes, that’s a nod to Frank’s hat’s on the show 30 Rock.

This one might be my favorite. Too soon?

Ok, back to the tip. Having a limited supply chain can cause delays as you end up struggling to find suppliers, and it’s possible to have to make changes to your design based on their manufacturing capabilities or limitations.

Knowing this, significant effort was put into getting users of Fusion 360 connected to this side of the process as early as possible. This takes the form of not only integrated CAM, but also the direct connections to 3D Printing, RFQ’s and suppliers via BriteHub, and manufacturability analysis and quotes via Proto Labs.

Check out this video to learn more and take the next step toward production: