RAYLASE, the Technical University of Munich and Autodesk combine their Expertise in Metal Additive Manufacturing to publish open software components aimed at enhancing the effectiveness of laser-based additive manufacturing equipment development.

RAYLASE is a market leader in high-precision components for deflecting and controlling laser beams used in laser material processing across various industries. These applications include Automotive, Battery Production, Solar Wafer Production, and Additive Manufacturing.

The Institute for Machine Tools and Industrial Management at the Technical University of Munich is one of Germany’s premier research institutions in the field of production technology. The institute is especially renowned for its work in additive manufacturing.

To streamline the effectiveness of development organizations working on laser-based additive manufacturing equipment, RAYLASE and TUM teamed up with Autodesk. Together, they developed truly open software components for additive manufacturing to drive state-of-the-art laser powder bed fusion equipment.

The challenge

Creating a mature and industrial software stack for additive manufacturing machine tools is crucial for a machine developer’s success in the market. Traditionally, this required a significant effort from development teams. Often, it consumed dozens of years for tasks that are repetitive and not differentiated in the market, for example:

- Build file and user management

- User interface and network control mechanisms

- Data logging and visualization

- Integration in upstream CAD, CAM and CAE pipelines

By using TUM’s openly released software as a basis, combined with Autodesk’s and RAYLASE’s compatible product offerings, any OEM can now utilize off-the-shelf components in an end-to-end tool-chain. This significantly reduces the need for extensive internal R&D efforts.

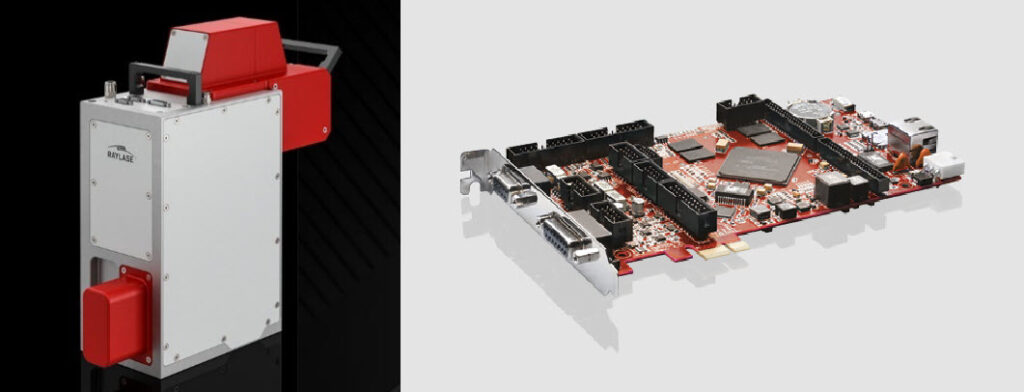

RAYLASE contributes with their SP-ICE 3 scan controller card and AM-MODULE-III, which address critical laser control issues and beam deflection synchronization. These are challenges that any machine tool builder in the additive manufacturing space faces.

- Industry proofed and LPBF dedicated deflection unit with high dynamic Zoom functionality

- Native integration of the nLight AFX laser that supports beam shaping

- Automated, fast and precise calibration solution (SFC-600) meeting highest calibration requests even with multiple scan fields

- Software tool for process monitoring and quality control with the RAYBOARD process data analyzer

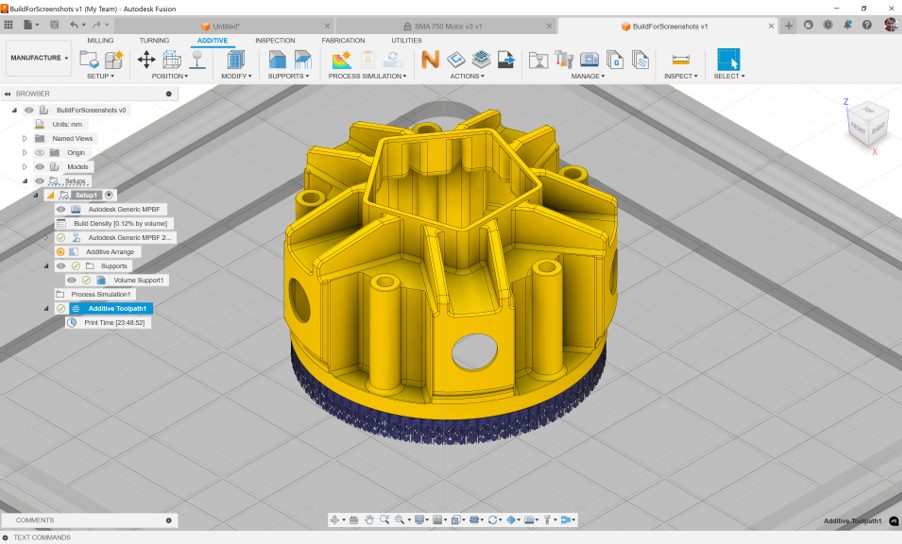

Autodesk Fusion offers an easy to use and affordable solution for data preparation, toolpathing and CAM, including:

- In-CAD design for AM modifications

- Parametric support structure generation.

- Slicing and toolpath processing, including any form of customized exposure strategy and free attachment of metadata to any toolpath element.

- Predictive metal process simulation and power optimization.

- 3-5 axis CNC postprocessing

This combination delivers a complete commercial software stack that allows you to build your own equipment with ease.

An industrial grade reference implementation

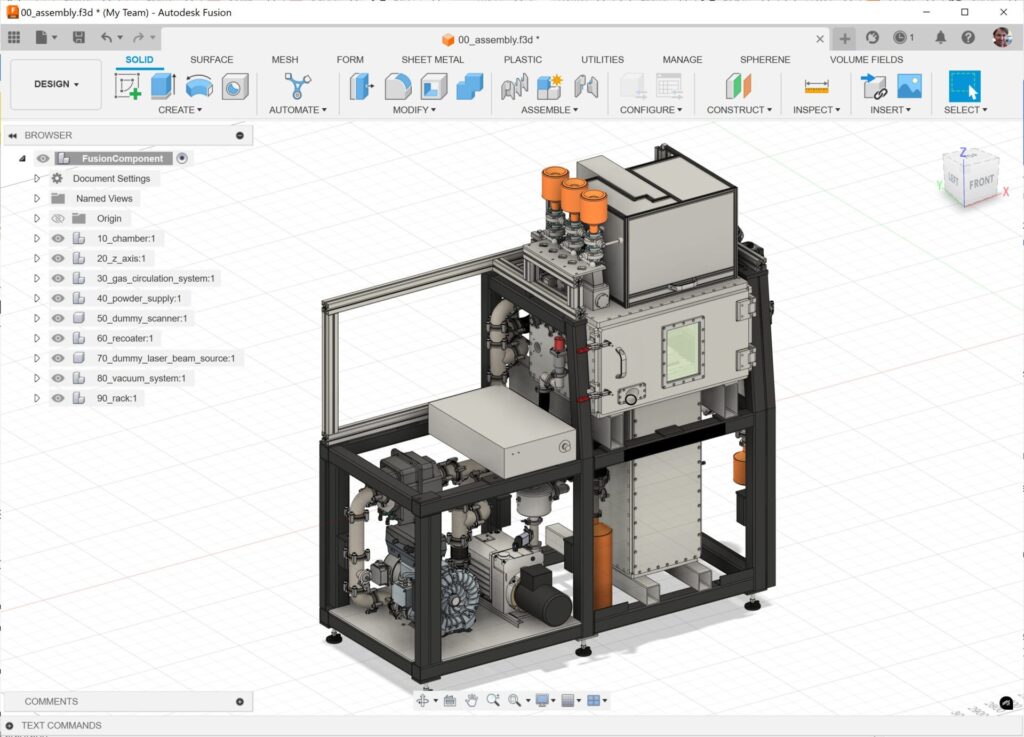

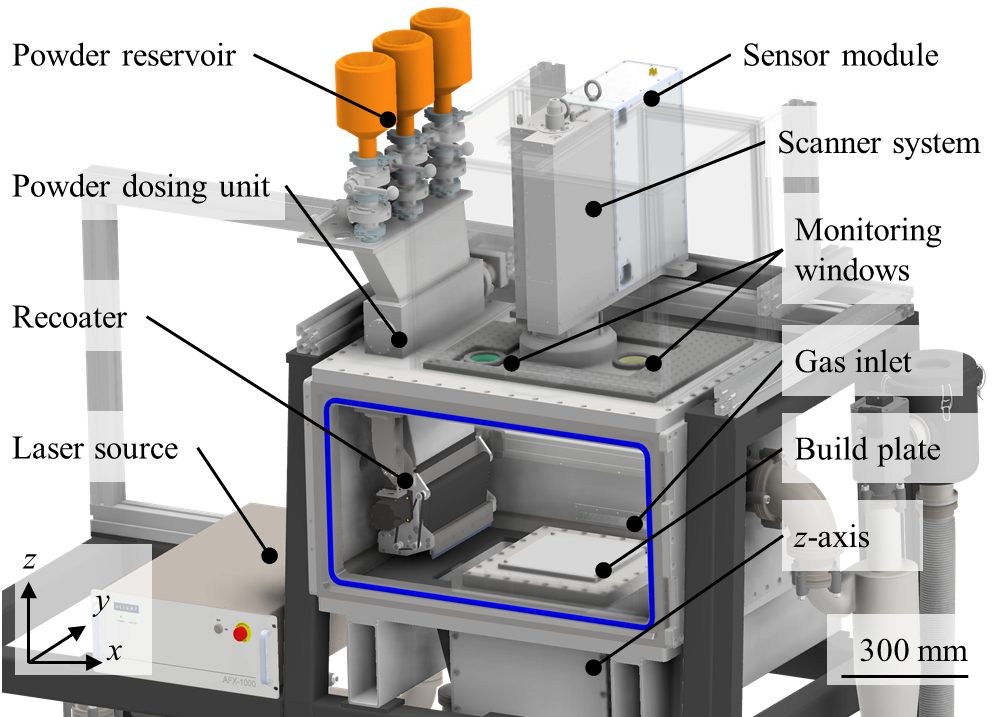

As a baseline reference implementation, TUM’s Institute for Machine Tools and Industrial Management took the extraordinary step of creating the open source research platform “reAM250.”

The reAM250 project not only covers a high-level machine concept but also provides a collection of all the software and digital documentation needed to easily rebuild the system from scratch as a third party. This includes:

- CAD drawings (In Autodesk Inventor and Autodesk Fusion)

- PLC software (Based on B&R Industrial Automation‘s Automation Automation Studio)

- Machine software (Based on the Autodesk Machine Control Framework)

- Bill of materials, circuit and IO diagrams

Everything is licensed under a permissive BSD license, so industrial reuse is encouraged, even for proprietary commercial developments.

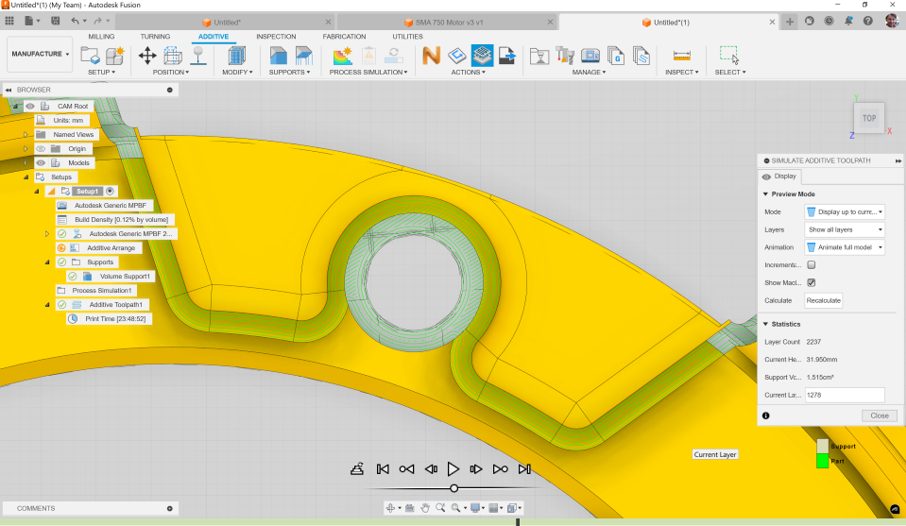

The above software stack connects as middleware the Autodesk Ecosystem (Autodesk Netfabb and Autodesk Fusion) with the RAYLASE Scan Controller API. Through extensive transport mechanisms of Metadata, it enables the set up of all relevant process parameters upfront in the CAD system – and directly passes them through to the scanner control cards and its connected deflection units. This works for many configurations and multiple lasers. Based on the open industry standard 3MF, this allows flexible research with arbitrary information flowing through the process without data loss.

The possibilities are pushing the frontier of research, allowing for:

- Laser power ramps and spot magnification

- Varying beam shapes within regions of a layer

- Sensor fusion and data driven quality assurance

For more information, refer to the peer-reviewed publication:

Wenzler et al., “reAM250 — An open-source research platform for process monitoring and control in Powder Bed Fusion of Metals using a laser beam”, Procedia CIRP, 2024, doi: 10.1016/j.procir.2024.08.121

The public code and documentation can be found on the project website:

- View the Project Documentation.

- View the CAD Drawings online in the Autodesk Viewer.

- View the PLC and Control Code on Github