& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

2 min read

Circle segment cutters in Fusion reduce cycle times and maintain high-quality finishes, enhancing efficiency and profitability in machining complex geometries.

The way a component’s geometry is machined significantly impacts both cycle duration and surface finish quality. These factors can either increase or decrease the total cycle time. This directly affects the cost of the component and your profit margins.

Planar or single-curvature geometries can be efficiently machined to a quality finish using the flat bottom or side edge of a cutting tool. However, doubly curved or organic shapes require a different approach, typically utilizing a spherical-tipped cutting tool like a ball endmill. This tool steps across the geometry to match its contours. After each stepover, a small ridge of material is left on the surface, influenced by the tool’s radius and the stepover distance. A smaller cusp results in a better finish but increases machining times.

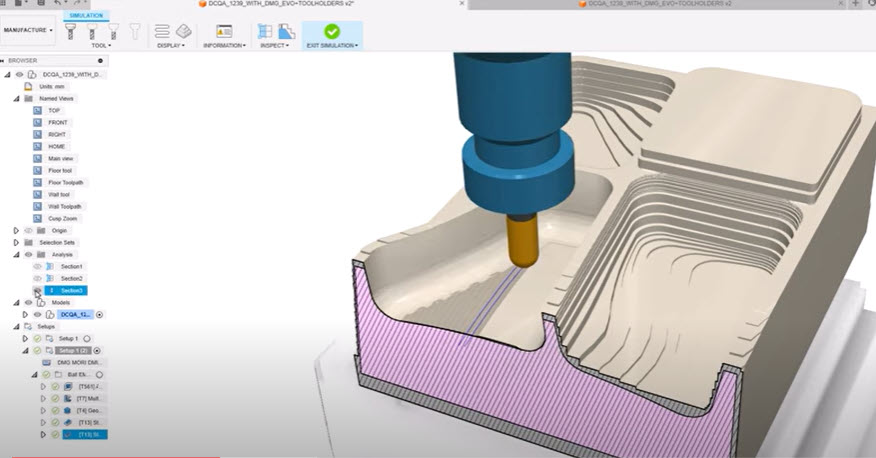

Autodesk Fusion’s multi-axis finishing strategy addresses this by reducing cycle times while maintaining surface quality through the use of circle segment cutters.

Circle segment cutters, such as lens, barrel, taper, and oval tools, feature large radiuses integrated into their complex cutting geometries. This allows for larger stepovers during machining compared to a ball endmill. Thus decreasing overall cycle time while maintaining the small cusp needed for a high-quality surface finish.

The multi-axis finishing strategy employs these tools for machining both shallow angled geometry (defined as a floor) and steep geometry (defined as a wall). Lens-type tools are particularly useful for machining floor geometry as the radius is located on the tip of the tool. The faces to be machined are defined, and a toolpath offset type is selected. These be automatically created, manually selected, or chosen based on the longest edge.

Barrel, taper, and oval tools are beneficial for wall geometry as their large radius on the side of the cutter allows for increased stepdown along the surface. The floor and wall surfaces are defined to specify the correct area to be machined and its limits. There are two toolpath pattern options to meet your needs: a scallop or a blend from top to bottom.

Circle-segment tools can increase the stepover distance, but they must be positioned at the correct angle so the large-radius profile contacts the surface during machining. Tool axis control is crucial to maintain this correct angle. Multi-axis options can be set to automatically tilt the tool during multi-axis movements or be user-defined, allowing the user to specify a unique lead angle and manually control the minimum and maximum contact points of the tool.

The combination of Fusion’s multi-axis finishing toolpath strategy and circle segment tools enables you to decrease cycle times and increase profits while maintaining the high-quality surface finish desired when machining complex part geometries.

Discover how the machining process of a component’s geometry can directly impact your cycle time and surface quality. With Autodesk Fusion’s multi-axis finishing strategy, you have the power to optimize both time and quality! Not only can this streamline your process, but it also directly boosts cost-efficiency and profit margins. Experience the benefits of using circle segment cutters and see how it revolutionizes your workflow.

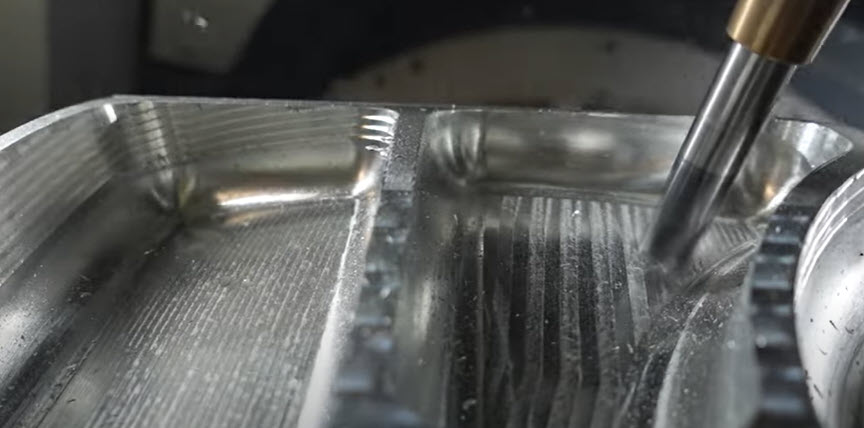

This machining footage was taken during testing at the Autodesk Birmingham Technology Center. That’s right – Autodesk Fusion tests and develops the next generation of technology on its own machines.

By clicking subscribe, I agree to receive the Fusion newsletter and acknowledge the Autodesk Privacy Statement.

Success!

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.