Mechanical engineering drives innovation in product design, requiring precision, efficiency, and optimization. Autodesk Fusion offers tools to streamline design processes, enhance collaboration, and maximize mechanical design potential. This guide explores mechanical design optimization with Fusion, focusing on practical applications and functionalities that empower engineers.

Mechanical design revolves around balancing performance, cost, manufacturability, and other factors. Fusion aids this process with iterative design refinement and advanced simulation tools, ensuring designs meet and surpass performance expectations.

Parametric modeling

Parametric modeling in Fusion, enables engineers to establish relationships and constraints within designs. This approach allows for iterative adjustments and ensures coherence throughout the design lifecycle. Engineers can define precise geometric relationships and constraints, allowing for real-time updates and adjustments as the design evolves.

Imagine designing a robotic arm. Engineers use Fusion’s parametric modeling capabilities to define key parameters such as joint angles, link lengths, and actuator sizes. By establishing these relationships, they can iteratively optimize the arm’s performance characteristics, such as range of motion and payload capacity, while maintaining structural integrity and minimizing weight.

Simulation and analysis

The simulation features in Fusion are integral to validating designs before physical prototyping. FEA and CFD simulations enable engineers to conduct comprehensive virtual tests under various conditions, optimizing designs for performance and efficiency.

Finite element analysis (FEA)

FEA in Fusion allows engineers to simulate static and nonstatic behaviors of designs. By applying loads, constraints, and material properties, engineers analyze stress distribution and deformation within components. This analysis identifies potential weak points and allows for iterative improvements to optimize structural integrity and performance.

Consider a car suspension component. Engineers use Fusion’s FEA to simulate stress distribution. By analyzing load conditions like braking and cornering, they optimize the part to withstand forces while minimizing weight, enhancing both performance and efficiency.

Computational fluid dynamics (CFD)

CFD simulations in Fusion analyze fluid flow and heat transfer within systems like aerodynamics, and industrial processes. Engineers can optimize component designs to ensure efficient performance and energy utilization.

Consider electronics cooling. Engineers use Fusion’s CFD capabilities to analyze airflow patterns and thermal management within devices. By optimizing cooling designs and using generative flow, engineers enhance performance and reliability, reducing overheating risks and improving energy efficiency.

Practical applications and benefits

Integrating FEA and CFD simulations within Fusion provides several benefits across industries:

- Aerospace: Optimizing aircraft component designs for weight reduction and structural integrity.

- Consumer Electronics: Enhancing thermal management and reliability of electronic devices.

- Energy Sector: Improving the efficiency of turbine blades and renewable energy systems.

Additive manufacturing

Additive manufacturing (AM) transforms production processes by enabling intricate geometries and lightweight structures that traditional methods cannot achieve. Fusion seamlessly integrates with AM processes, empowering engineers to optimize designs for 3D printing directly within the software environment.

This capability is particularly advantageous in industries like aerospace, where engineers leverage Fusion’s automated manufacturing tools to prototype and produce complex components with reduced lead times and material waste. For instance, in spacecraft design, engineers use AM to create lightweight structural components that enhance payload capacity and mission efficiency.

Collaborative tools

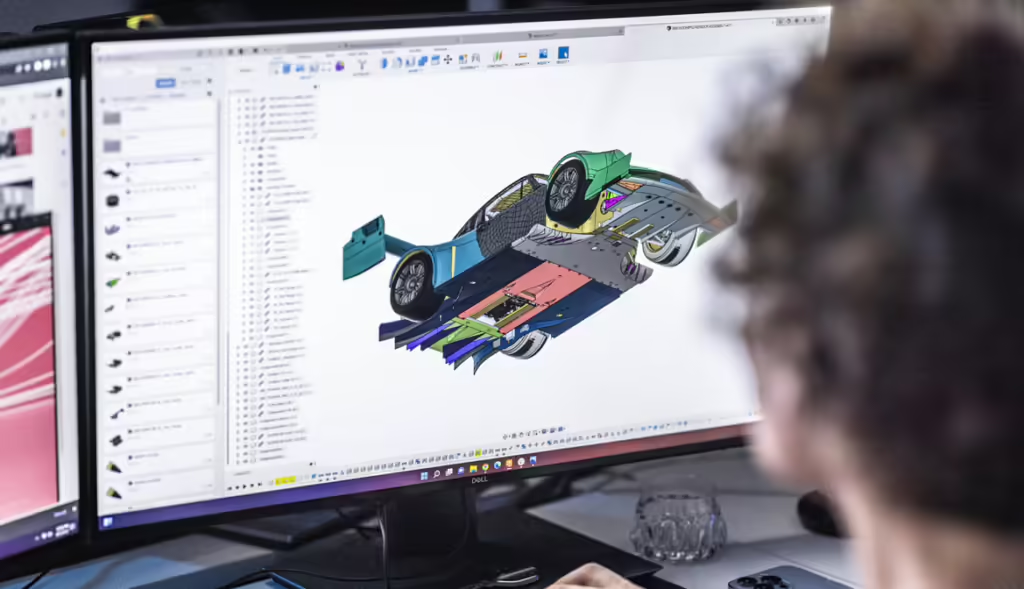

Efficient collaboration is essential for successful design projects, and Autodesk Fusion’s cloud-based tools facilitate real-time collaboration and data management. Multi-user capabilities allow team members to work simultaneously on projects, enabling seamless sharing of ideas, feedback, and design iterations.

In automotive design, for example, cross-functional teams use Fusion’s collaborative tools to develop and refine vehicle prototypes. Designers, engineers, and manufacturing experts collaborate in real time, optimizing vehicle component performance, safety, and aesthetics before moving into production.

Advanced materials and composites

Fusion enables engineers to simulate the behavior of advanced materials and composites within design environments. By defining material properties such as elasticity, strength, and fatigue resistance, engineers can analyze how these materials perform under various stress scenarios and environmental conditions.

In renewable energy technologies, such as wind turbine blade design, engineers leverage Fusion to optimize the performance of composite materials. By analyzing stress distribution and material fatigue under varying wind conditions, engineers enhance blade efficiency and longevity.

For example, engineers use Fusion’s simulation tools to model the behavior of composite materials used in wind turbine blades. By simulating the interaction of materials with wind forces, engineers optimize blade designs to withstand high loads and turbulent conditions, thereby improving energy capture efficiency and extending operational lifespan. This iterative process of material optimization ensures that wind turbines operate reliably and contribute effectively to sustainable energy production.

Environmental impact and sustainability

Engineers harness Fusion to design products with reduced environmental footprints, emphasizing sustainability through lightweighting, energy efficiency, and recyclability. Fusion’s lifecycle analysis tools enable comprehensive assessments of environmental impacts, guiding decisions that minimize effects throughout a product’s lifecycle.

In consumer electronics, for instance, engineers utilize Fusion to optimize energy efficiency by simulating power consumption and heat dissipation. This approach ensures compliance with stringent standards while reducing environmental impact during use and disposal. Fusion supports engineers in promoting recyclability through innovative designs that facilitate material recovery, contributing to a circular economy model.

Human factors and ergonomics

Autodesk Fusion supports engineers in designing products that prioritize user comfort and safety through ergonomic analysis and simulation. For instance, in ergonomic chair design, engineers use Fusion to simulate posture support and comfort, optimizing designs for prolonged use and minimizing user fatigue or injury.

By analyzing anthropometric data and ergonomic factors, engineers ensure that products meet ergonomic standards and enhance user productivity and well-being in various environments, from office spaces to industrial settings.

Design for manufacturing (DFM)

Fusion plays a pivotal role in advancing Design for Manufacturing (DFM) principles, enabling engineers to optimize product designs for seamless production, assembly, and maintenance. By integrating DFM practices early in the design process, engineers can identify and address potential manufacturing challenges, leading to reduced costs and shorter lead times. For example, engineers can use Fusion to ensure that a product’s parts are designed for easy assembly using standard fasteners and minimal tooling.

Optimizing production efficiency

In industrial machinery design, engineers rely on Fusion’s DFM tools to simulate manufacturing processes and assess the feasibility of assembly sequences. By visualizing assembly steps and optimizing part orientation and tolerances, engineers streamline production workflows and enhance manufacturing efficiency. This proactive approach minimizes production errors and reduces the need for costly rework, ultimately improving overall product quality and customer satisfaction. For example, a company manufacturing conveyor systems can use Fusion to optimize the placement of components to simplify assembly and reduce production time.

Streamlining manufacturing workflows

Fusion’s intuitive interface and robust simulation capabilities empower engineers to iterate designs rapidly, ensuring optimal manufacturability. Engineers can analyze material selection, tooling requirements, and production techniques within Fusion’s integrated environment, facilitating informed decisions that align with production capabilities and cost-efficiency goals. As an example, a medical device manufacturer can use Fusion to select biocompatible materials and appropriate manufacturing methods, ensuring the final product meets regulatory standards while being cost-effective to produce.

Application across industries

Beyond industrial machinery, Fusion’s DFM capabilities are applicable across diverse industries, from automotive and aerospace to consumer electronics and medical devices. Engineers leverage Fusion’s comprehensive tools to design components and assemblies that not only meet performance criteria but also streamline manufacturing processes, reducing time to market and enhancing competitiveness. For instance, in the automotive industry, Fusion can be used to design parts that are easier to manufacture and assemble, such as optimizing the design of engine components to reduce the number of manufacturing steps and improve fuel efficiency.

Real-world example: tousek’s success story

Vienna-based automatic gate company tousek leverages Fusion and its extensions throughout its product development process. During the pandemic, tousek experienced remarkable growth as people invested more in their homes. Facing challenges with consumer demands for speed and safety combined with changing regulations, they switched to Fusion. This enabled them to react quickly to regulatory changes and optimize the design of mechanical parts. With features like the Fusion Simulation Extension, and Product Design Extension, tousek improved their design and manufacturing process efficiency, allowing for rapid iteration and better collaboration across departments. This resulted in fewer errors, reduced costs, and accelerated production timelines, contributing to their successful expansion.

Fusion empowers mechanical engineers to innovate with precision and efficiency. With tools for parametric modeling, simulation, additive manufacturing, and collaboration, Fusion tackles complex design challenges and delivers superior solutions. Explore Fusion’s educational resources and practical applications to elevate your projects in performance, reliability, and sustainability. Harness Fusion today to optimize your mechanical designs!