Radio-Frequency Identification (RFID) has been around for over 50 years, and in the last decade is finally cheap enough to mass-produce and place in everyday objects. This presents some new opportunities for electronics designers wanting to learn about RF and antenna design. While RFID accomplishes the same functionality of a barcode or magnetic strip on a credit card, it has some unique use cases that make it worth learning about and designing. In this blog, we’ll be covering how RFID works and how you can create your very own RFID tag antenna circuit.

How RFID Works

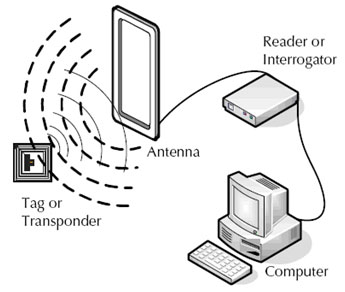

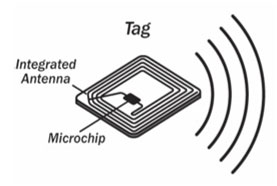

An RFID system consists of three parts: a scanning antenna, an RFID tag which includes all of the information about a product, and a reader which decodes and interprets data on a tag. These three pieces fit into a process where:

- Data is first stored in an RFID tag in either a read-only or read-write format. The tag is either battery powered or passive.

- When the tag comes within range of a scanning antenna, electromagnetic (EM) energy triggers the tag to start sending data in the form of radio waves.

- These radio waves are picked up by the antenna and send to the reader which decodes the waves as digital information.

RFID tags are broken down into one of two types, Active and Passive:

Active RFID Tags

Active RFID tags use an internal battery source to power their circuitry and send radio signals. Because of their battery power, active tags can broadcast at higher frequencies from 805 to 950 MHz. This allows them to be scanned from up to 100 feet away.

| Advantages | Disadvantages |

|

|

Passive RFID Tags

Passive RFID tags have no battery source and rely on the electromagnetic coupling of an antenna for their power. This leaves them with a shorter reading distance of up to 20 feet. However, because they have fewer components in their circuitry they’re also cheaper to produce and disposable. This is the kind of tag you’ll find in consumer-level products.

| Advantages | Disadvantages |

|

|

All RFID tags are classified by their Generation and Class. Current Gen-2 RFID tags were adopted in December 2004 and offer several advantages over Gen-1, including:

- Interoperability with all RFID systems, the first global standard

- Faster read speeds than Gen-1

- Precise performance with advanced anti-collision protocols

- Improved security and privacy

- Easier physical deployment of multiple readers

RFID tag classes range from Class 0 through Class 5 and define available functionality. Class details include:

| Class | Functionality |

| Class 0 | UHFI read-only, preprogrammed passive tag |

| Class 1 | UHF or HF, can be written once, read many times (WORM) |

| Class 2 | Passive read-write tags that can be written at any time |

| Class 3 | Passive or active read-write tags with added sensors for recording temperature, pressure, and motion. |

| Class 4 | Active read-write tags with integrated transmitters that can communicate with other tags and readers. |

| Class 5 | Active read-write tags that can power other tags and communicate with external devices other than readers. |

Advantages and Disadvantages of RFID

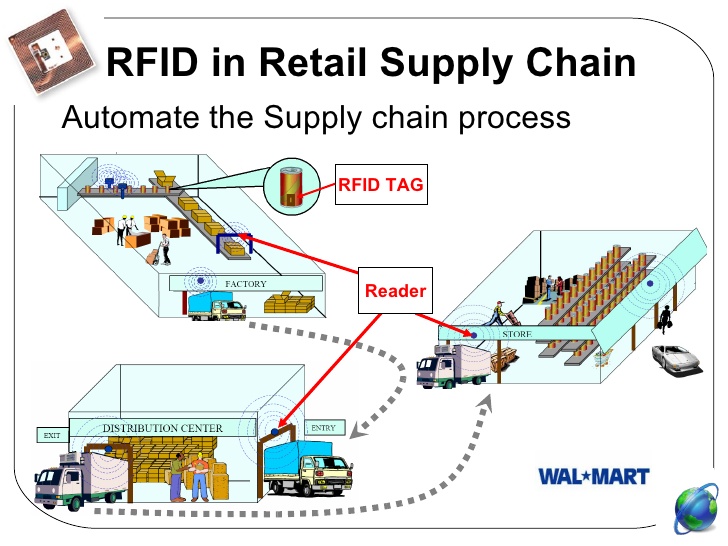

RFID wireless technology has provided enormous benefits to logistics, inventory control, and retail industries, but that doesn’t make it a perfect technology. However, when compared with barcodes and other manual scanning systems, RFID has some noticeable advantages, including:

- Scanning multiple items simultaneously. RFID systems can scan all incoming items at once, compared with an optical scanner which can only handle one item at a time.

- Reduced costs. Costs have fallen dramatically to manufacture active and passive RFID tags, which makes them available for use in disposable consumer products.

- Read and write capabilities. Barcodes can only be written with data once, but RFID tags can be updated as many times as needed for Class 2 tags and above.

- No line of sight issues. Unlike optical scanners, there are no line of sight requirements when scanning items. This makes RFID ideal for high efficiency industrial environments.

The disadvantages for RFID fall into two categories, technical issues related to RFID implementation and security/privacy uses.

- RFID can be disrupted. Someone using the right frequency on the electromagnetic spectrum can potentially jam an RFID system. You can also continually read a battery-powered RFID tag until it powers down.

- Reader collision issues. Systems need to be carefully set up to avoid any collision issues where multiple signals overlap. This has been improved with Gen-2’s improved anti-collision protocols.

- Can be read at longer distances. Most RFID systems are designed to work at small distances. However, with a high-gain antenna, you can read tags from over a hundred feet away without anyone knowing.

- Can be read without permission. As we begin to embed RFID in everyday items like clothing and consumer products, we’re also at the mercy of stores scanning every item we’re carrying to prevent theft. Is this an issue of privacy, or just the cost of convenience?

Use Cases for RFID

With its lower manufacturing costs, the uses for RFID are spreading across a variety of industries and settings. Some of the most common applications we see today include:

Retail and Inventory Control

RFID tags are attached to clothing and other consumer goods in retail stores. This allows employees to scan items and track inventory levels without dealing with barcodes.

Subway passes and toll booths.

RFID tags are commonly added to toll booths, and subway passes. This allows commuters to swipe a card and automatically deduct the cost of the fare.

Theft Prevention

High priced, luxury items like custom-built guitars are now having RFID tags embedded inside them. This inventory is then shared with local law enforcement, dealers, and repair shops to help prevent theft.

These are just a few of the many uses for RFID. In the future, this technology is proving to be a major disruptor for the retail shopping experience with concepts like Amazon Go. Some other use cases for RFID include:

- Person and animal tracking

- Contactless payments with NFC

- Travel documents

- Healthcare data management

- Tracking shipping containers and railroad cars

Designing Your First RFID Antenna Tag Circuit

When designing an RFID system, engineers will typically utilize exiting tag microchips like the STMicroelectronics ST25 in combination with a custom antenna. In this section, we’ll be covering some practical tips on how to approach this antenna design process, along with further details in an application note.

Know the Frequency of Your Application

Before designing a custom antenna, you need to know the frequency of your application. Nearly all RFID systems operate in two lower-frequency bands, either 13.56 MHz or 125 KHz, both of which are applicable in almost every country. Within the 13.56 MHz band, your application can be categorized as:

- Long Range (LR). These products are tuned between 13.6 MHz and 13.7 MHz.

- Standard Short Range (SR). These products are tuned between 13.6 MHz and 13.9 MHz.

- SR products being used as transport tickets are turned between 14.5 MHz and 15 MHz.

To determine the frequency of your application you also need to consider the material and environment of your device. For example, an RFID tag with a paper label held together with adhesive will reduce the antenna frequency by about 300 KHz. This reduction makes it necessary to tune the antenna at 13.9 MHz instead of its specified 13.6 MHz.

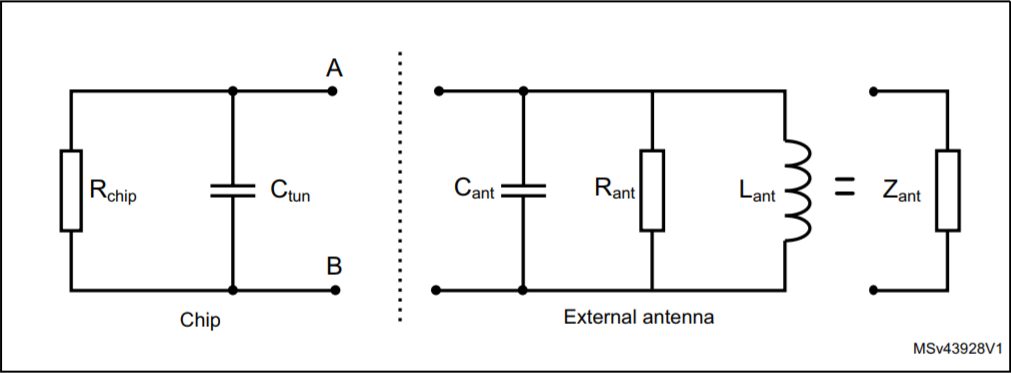

Reference an Equivalent Circuit Model

Many antenna design application notes will include an equivalent circuit model that you can follow when designing your own. The schematic below shows how the chip and antenna fit together in a typical circuit:

The Chip

- The chip circuit is referenced by Rchip and represents current consumption in parallel with capacitor Ctun

- Ctun defines the chip’s internal tuning capacitance and internal parasitics.

The Antenna

- Cant. Determines the stray capacitance

- Rant. Determines the resistance loss

- Lant. Determines the self inductance

Determine the Inductance of Your Antenna Coil

At 13.56 MHz your antenna design will either be circular, spiral, or square shaped. What shape you use will depend on your design requirements. Below are three formulas you can use to determine the inductance for your specific antenna type quickly:

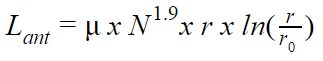

Circular Antenna Inductance

- r is the mean coil radius in millimeters

- R0 is the wire diameter in millimeters

- N is the number of turns

- 0 = 4π x 10-7 H/m

- L is measured in Henry

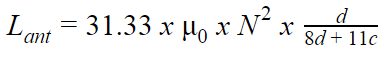

Spiral Antenna Inductance

- d is the mean coil diameter in millimeters

- c is the thickness of the winding in microns

- N is the number of turns

- 0 = 4π x 10-7 H/m

- L is measured in Henry

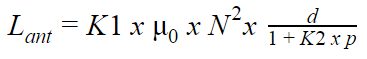

Square Antenna Inductance

- d is the mean coil diameter

- d = (dout + din) / 2 in millimeters, where dout = outer diameter and din = inner diameter

- p = (dout – din) / (dout + din) in millimeters

- K1 and K2 depend on your antenna layout, see the table below for values

| Layout | K1 | K2 |

| Square | 2.34 | 2.75 |

| Hexagonal | 2.33 | 3.82 |

| Octagonal | 2.25 | 3.55 |

Read the Full App Note

The details we covered above just scratch the surface of designing a custom RFID tag antenna. Be sure to read the full application note for STMicroelectronics on How to design a 13.56 MHz antenna for ST25 RFID tags.

Wireless Magic

RFID takes advantage of radio waves to read and capture information stored on tags that can be attached to a variety of objects. From high-dollar guitars to pets and shipping containers, the uses for RFID are almost limitless. This technology is poised to be a replacement for the standard barcode and magnetic strips in the future, but what will that future look like? If it’s anything like what Amazon Go has envisioned, we’ll soon be enjoying a shopping experience without any of the tedium of lines and checkouts. But what does all of that mean for our personal privacy?

Ready to design the future of wireless electronics? Get started today with the ST25 RFID tag microchips from STMicroelectronics. Then design your custom antenna with Autodesk EAGLE!