& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

11 min read

Originally posted by keqingsong on 09-06-2016 12:34 PM

Time flies when you’re working on a project that you’re truly passionate and excited about. We’ve made a lot of progress since our last check-in, but it wasn’t all easy sailing, as we also experienced challenges and inevitable turbulence along the way. We learned from those experiences and saw opportunities to make Fusion 360 the best product design platform that has ever existed.

Based on your feedback through face to face conversations, phone calls, emails, forum threads, meet-ups, and social media, we’re hunkering down and and making sure that the foundation of the software is solid. For the second half of the year (H2), we’re putting our efforts into these three guiding areas of focus:

You will enter this mural in View Only mode.

With the guiding areas of focus in mind, we’ve updated our priorities. The roadmap in Mural will give you a recap of what we delivered first half of the year, as well as a view into what we’re working on for the rest of the year. Note that we’re only highlighting the big nuggets, and did not include absolutely everything the Fusion team is working on (that would be too long of a post for me to even thinking about writing). In the coming months, we’ll be sharing more details around the projects mentioned here on our Design Differently blog, so look out for those Fusion Forecast posts!

Okay, let’s get this party started.

Every piece of software has its quirks, and Fusion is no exception. For H2, we’re making sure that our data management workflows handle unexpected service outages in a way that you’ll never end up in situation where you can’t do your work.

We’re also improving our process of pushing updates, so that you can get fixes and improvements to high priority tools as soon as they become ready.

Speaking of fixes, the devil is always in the details. This means working on creating better testing automations, so we can catch and fix more issues before they hit you.

Downloading and installing Fusion is pretty straightforward, but when there’s an issue, it’s not easy to figure out what exactly went wrong. This is another area of the experience that we’re working on, making it more reliable, more forgiving, with better solutions to issues if they do come up, with the highest amount of data security.

With Deep Update and Mesh preview now available, we’ve been working hard on making improvements to our core modeling tools, sketching experience as well as the highly anticipated sheet metal functionality.

Enhancements to Core Modeling

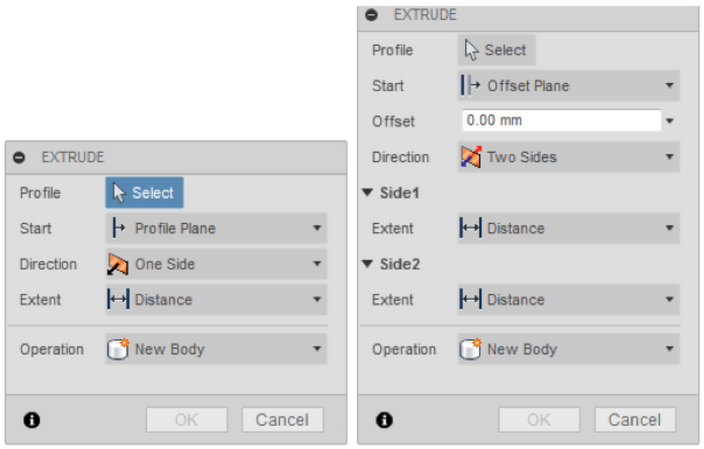

This is at the core of Fusion 360, and we’re working on improving high-usage tools such as the Extrude and Fillet commands so that they are more intuitive and more robust.

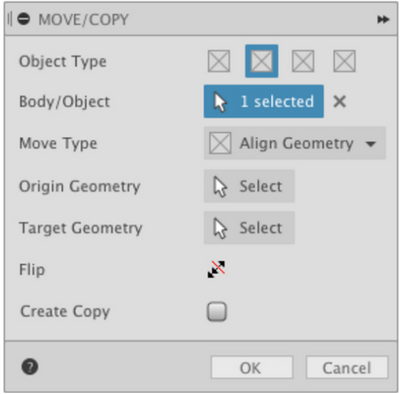

Improvements to Move and Align are also coming. We took your feedback and are making the Move tool parametric, so you can specific values to and drive your moves parametrically. Along this thinking, we’re also improving the Align tool, making it easier to snap 3D geometry point to point.

Having Fillet and Rule Fillet as two separate commands always felt odd to us, so we’re working on combining them and simplifying the workflow, while making face fillet will be more discoverable too. We’re not stopping there either, as we plan to add full round, face to face along with a few other enhancements to improve your overall fillet experience.

We’re also focusing on making sure the timeline is more responsive, especially when you’re trying to make changes to your design history and trying to reorganize features.

Improving modeling experience and Usability

Trying out a new piece of software is all it takes to make or break the deal. We are constantly refining this experience and want to make sure that when you get into Fusion for the first, you are equipped with the right tools and are ready to get productive. We are also working on usability improvements such as fixing the grid gradient, enabling browser folders, and introducing a tabbed toolbar experience, as well as the “Fusion wants my attention” issue.

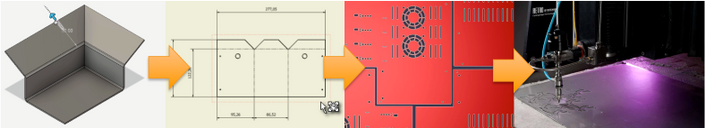

Sheetmetal

We’re making good progress here. The main workflows we’re focusing on are Press Brake workflows and how we can make it simple and logical. We have rules and flanges pretty much nailed down (Face, Contour, Edge, Miter Flange), and are now working on fold/unfold and flatten tools. We’re not sure exactly when we’ll have a first release to for you to play with, but we’re on the right track.

After our initial release, we plan on adding features that allows you to bring in other sheet metal CAD models to incorporate into a design and/or to flatten the design. We also see the need to have the ability to convert designs into a sheet metal model. Looking further out, our goal is to provide a complete design-to-manufacture workflow that includes designing your sheet metal part, to flattening it, to nesting it, all the way to manufacturing with laser / waterjet / router.

In addition to some of the things we mentioned in the previous check-in, we also were able to deliver some nice improvements to the Move command, Part list behaviors, a slight UI refresh and a cursor change to a pointer that we all recognize.

For the month of September, we’re on track on delivering features such as Inserting your own DWG title-blocks, as well as rotating views. We started to work on the other items for H2, but still do not have a timeframe for when they are going to be available quite yet.

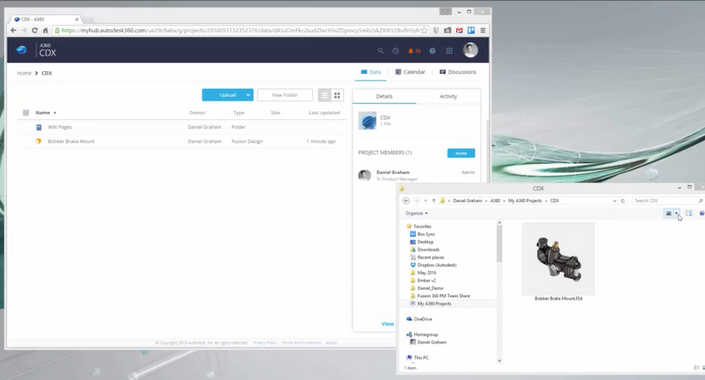

Our idea for how people should manage their data in Fusion has always been an “Eyes Wide Open” concept with transparency throughout the collaboration process. Branching & Merging preview functionality is right on the cusp of becoming available. The cake is pretty much done, we just need to let it sit and put the icing on and it’ll be ready. Expect it to show up in the next couple of months.

We also got word that Connected Desktop is almost ready. It is currently in the testing phases and we are working on getting it all wrapped up. We will share more details around this when we get closer to a delivery timeframe.

If you haven’t seen it in action yet, it’s worth a look.

For the second half of the year, we’re focusing on the core aspects of what makes data management so great in Fusion. The experience has come a long way since our first iteration with the dashboard (dear lord was that hideous), and with all the feedback we are getting, we’re working making this existing experience rock solid. Our teams are working on things like:

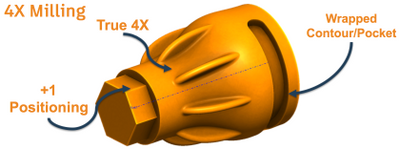

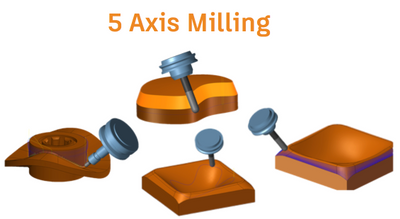

The CAM experience in Fusion has seen a lot goodies, and since it’s built on the HSM kernel shared by both Inventor HSM and HSM Works, improvements made on the HSM code is shared throughout all products. So yeah, Fusion’s CAM capabilities are legit, but we still have tons of work to do. In order for our team to keep track of what to work on, we’ve split the work into three major categories:

Completing the last mile – These are projects that center around better connectivity with the machine as well as capturing better defaults for things like speeds and feeds. Today, the bulk of these efforts are focused on the post processors and tool library. In recent updates you have seen things like the consolidated manage and select tool dialogs as well as a slew of new post processors for machines like Okuma, Fagor and stepcraft.

Workflow completeness – You can do a lot in the CAM workspace today, but it is still lacking functionality to really enable you to use your manufacturing processes to their full extent. To deliver on this goal, we’re focusing on:

Quality of life – As we work projects in those first two categories, we take bug fixes and usability improvements very seriously. These come from our IdeaStation and forum (and since Fusion shares the same kernel as Inventor HSM and HSM Works, we have multiple forums that we keep track of). This is where we’ve been spending a lot of our time on in the past couple of updates, and you will see more of these fixes trickle in throughout each update.

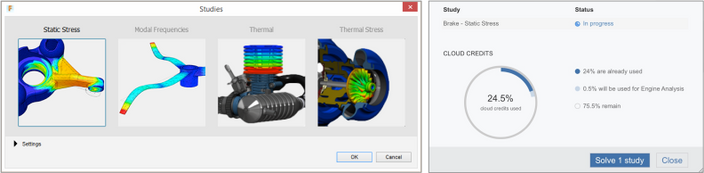

Since the addition of the Simulation workspace, we are building the easiest simulation setup and evaluation experience in the market. We were not able to fit cloud simulation in for summer, but we are planning to bring it into the mix during the Fall, followed by more advanced Sim functionality towards end of the year. We didn’t go into much detail in the May check-in, so here are some on the new solvers and upcoming tech.

Topology Optimization – Nastran also brings us some great shape optimization capabilities. We will start with a simple workflow to “light weight” designs based on Sim feedback to the expected loading conditions. The result will initially be a mesh body that you can bring into the new Mesh environment, but we plan to round trip the workflow so that the mesh can turn back into a body in future updates.

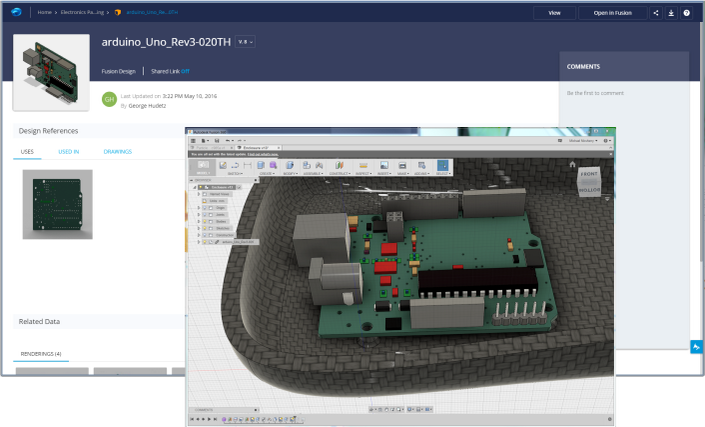

For past 3 months, our teams have been investigating workflows and putting together a plan around how we can integrate ECAD into the Fusion 360 ecosystem. Electronics is a crucial element to the product design process and we’re determined to bring these 2 worlds together, like some kind of a fusion (that was a terrible pun, you’ll never hear me say that again).

With the great folks at Eagle PCB Design joining forces, we are currently working through the first phase of this project, which is the ability for A360 to recognize a PCB file format and translate it so that it can be opened in Fusion as a read-only/cross-referenceable design. We baked this into A360 so that all of our design management versioning and tracking can help keep everything up to date. Aiding this process is a robust library tool that can map your board components from 2d blandness into full 3d glory.

The long term vision is to make this a 2-way street. We can dive deeper into the thinking behind ECAD and workflow details in a separate Fusion Forecast post, but the good news is that we are striving to have demonstrable phase 1 experience ready to share at Autodesk University 2016.

We’re always listening. Always interested in how you use Fusion 360. Always striving to help you get what you need to be successful with your designs. Feel free to chat with us in the comment section below about your thoughts. If you just can’t get enough of Fusion, then you should come meet us at Autodesk University, where we’ll be demoing a number of project milestones mentioned in this roadmap check-in, among a plethora of great classes, keynotes, and parties. Thanks for being awesome, and we are looking forward to seeing you there!

Cheers,

Keqing and the Fusion 360 Team

A. Roadmaps are plans, not promises. We’re as excited as you to see new functionality make it into the products, but the development, release, and timing of any features or functionality remains at our sole discretion.

B. These roadmaps should not be used to make purchasing decisions.

By clicking subscribe, I agree to receive the Fusion newsletter and acknowledge the Autodesk Privacy Statement.

Success!

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.