Seamlessly access the Sandvik Coromant online tool library from within Fusion 360 with the Sandvik Coromant CoroPlus Tool Library Add-in for Fusion 360.

The most successful machine shops and manufacturing departments remove manual tasks that waste time and money or cause errors. One common challenge is deciding what cutting tools to use and how to use them. Historically, this important information only lived in a physical catalogue or online web page. Thus, transferring all the cutting tool information into CAM software, like Fusion 360, could be time-consuming and cause errors.

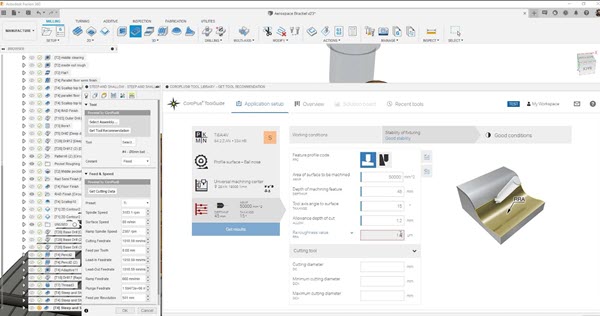

With the Sandvik Coromant CoroPlus® add-in for Fusion 360, you can drastically reduce the time and effort needed to select the right cutting tool, choose the correct cutting parameters, and transfer the data back into Fusion 360 for CAM programming to continue. Hence, faster CAM programming times, better machining outcomes, and reduced risk of error.

Autodesk Fusion 360 and Sandvik Coromant partnership

Sandvik Coromant is part of Sandvik’s Machining Solutions division. It’s one of the most recognized and respected suppliers of cutting tools for use within the manufacturing sector. Its integrated add-in for Fusion 360 allows users to access the entire online library of Sandvik Coromant CoroPlus tooling. In addition, it provides tried-and-trusted recommendations to help simplify the programming of the most challenging machining tasks.

The add-in is for Fusion 360 subscribers generating tool paths and NC code to drive CNC machinery, serving the needs of industries including automotive, aerospace, energy, and general engineering applications.

It allows you to access and choose a Sandvik Coromant tool and have the geometry appear in Fusion 360 without the need for manual entry. Further, you can build entire tool assemblies with the online library. You also gain access to tools from multiple suppliers that are always maintained and up to date.

In addition, the CoroPlus® Tool Library can recommend tried-and-tested cutting parameters (feed, speed, width of cut, depth of cut, etc.). These parameters are based on the unique CNC machine you are using and the stock material you are processing. They are even based on the type of feature you are machining (e.g., slot, hole, pocket, profile surface).

This helps greatly reduce the likelihood of mistakes happening. Thus resulting in better machining outcomes, including improved surface finish, faster cycle times, and better tool life.

“Sandvik Coromant adds tremendous value to the Fusion 360 community. Our manufacturing customers will now be able to quickly and easily integrate Sandvik Coromant’s tool data, helping to drastically decrease time spent identifying the correct tool and tool path,” said Stephen Hooper, VP of Design and Manufacturing at Autodesk. “This collaboration continues the expansion of Autodesk’s open ecosystem and enables customers to focus more energy on the engineering work that drives their business forward.”

3 primary business benefits

- Streamline CAM programming

- Automatically identify the right cutting tool assembly and machining parameters. Then, transfer to Fusion 360 with the click of a button for faster, more accurate CAM programming.

- Reduce the risk of defects and mistakes

- Increase CAM programming confidence and reduce the likelihood of broken tools, poor surface finish, or damaged workpieces on the shop floor. CoroPlus® Tool Library includes tried-and-trusted feeds and speeds for thousands of material types for safer, more predictable machining outcomes.

- Improve machine and cutting tool utilization

- Gain insights into the cost of your CNC machining operation based on tooling and machine utilization to extract maximum value from both. Further, explore different alternatives to find the right balance of cost and time based on your project needs and the capabilities of your CNC machine.

“One of the biggest bottlenecks with CAM programming today, is to create an accurate representation of the full cutting tool including adaptors, extensions, and collets,” explains Jonas Ström, Sales & Marketing Manager at Sandvik Coromant. “With the add-in this is no longer an issue. Users of Fusion 360 can now create 3D tool assemblies, find cutting data and seamlessly transfer all of that into the operations for a faster and more secure CAM programming process. This is exactly what this partnership between Autodesk and Sandvik Coromant is all about. Helping our customers stay competitive and profitable with new and innovative technologies.”

The Sandvik Coromant add-in in action

Autodesk Process Specialist Richard Stubley recently put the new add-in to the test. Take a look at the following 5-part “how-to” video series. Here, Richard explains how the add-in works and how it helped him manufacture a large titanium, aerospace bracket.

“I didn’t have a lot of experience machining Titanium, but the add-in worked like a dream,” said Stubley. “It lowered my stress levels and meant I could focus on programming the part the way I wanted to and not worry about what feeds and speeds to use. Our customers need to make sure they’re able to machine their parts right the first time, every time – I just know this add-in is going to help achieve this whilst also saving me (and them) a load of time and heartache.”

Check out the YouTube playlist below to learn more:

How to access the Sandvik Coromant add-in

To learn more about the add-in, visit the Sandvik Coromant site. To download the add-in for free, visit the Autodesk app store.