Not sure what to account for when production planning? Rock solid production scheduling involves considering everything during the preparation and manufacturing of your product.

When planning your production schedule, it helps to think about the bigger picture first. Then, you can consider the parts needed to execute your vision. Considerations include team size, production capacity, workflow, problem-solving, and understanding of the overall manufacturing process. In this article, we’ll cover each consideration in detail and how you can get ahead in your planning phase.

Team building: recognizing individual skills

Your team is the backbone of your entire operation. If you do not have an adequate amount of workers, your production pipeline will be slow-going and riddled with problems. To use your team to their potential, you need to understand how their individual skills play into your larger vision.

Managing your team is more than just assigning them roles and leaving them to their duties without oversight. You need to be proactive in their development and keep a steady watch on their progress; you have to be aware of what each person is best at and what they struggle with. Doing so allows you to train, coach, and assign your team members to areas they are most productive and happy.

Optimizing production capacity

This falls under general optimization for your productivity. It means ensuring that your pipeline is outputting at its maximum capacity. Even small slowdowns in one area of your production can bring your pipeline to a grinding halt. That’s why it’s important to maintain a good amount of oversight on your product output, and keeping an accurate production schedule is part of that. Keeping your milestones as the main priority helps you gauge how effective your management is and if your plant is operating at 100% capacity.

Logistics

The tiny details can make or break your operations. It’s critical to remember that fact when troubleshooting or addressing problems in your production. It may be that your equipment is in need of updating, or perhaps the team member you assigned to a specific task is not the proper choice for that station. These tiny logistical problems can be corrected if caught early. However, it’s not uncommon for organizations to ignore the small and end up paying for it later on.

Logistical problems have a way of accumulating, and part of preventing these problems from adding up is by referencing your production schedule. By doing so, you can pinpoint at which junction your pipeline is suffering problems and target your solutions much more efficiently.

Problem-solving with thorough documentation when production planning

When you maintain a production schedule, you can use it to narrow down your focus in the event of a problem. You need to ask yourself at which point in the pipeline is failure occurring, and this is only possible if you keep good documentation and tracking. Problem-solving should not drain your resources completely; there are many cases where companies exhaust valuable time and resources to root out the problem.

Understanding the manufacturing process

This is the most critical part where everything you know about your product comes into play. Simply creating a production schedule is not sufficient. You need to truly understand every part of the production process and build your schedule off of that. A methodical, systematic approach to tracking your production is the best way to maximize the skills of your staff, minimize the number of resources spent problem-solving, and get your focus back on track.

Pro tip: avoid basic spreadsheets when production planning

Excel and other similar spreadsheet generator platforms are useful for many tasks. However, think twice before using Excel to outline and implement your production schedule. While a powerful app that can execute a lot, it doesn’t measure up as a production tracker for the following reasons:

Slow

While good in a pinch, executing functions and designating tasks in Excel can be time-consuming and feel outdated when there is more efficient modeling software on the market. For example, where Excel lacks the function to work in real-time, Fusion Operations does not. You can adjust the calendar in Fusion Operations with a single click, which will automatically be available for everyone instantly. Additionally, Excel is very labor-intensive. Unless you’re up for coding a bunch of automation scripts in bash or zsh, you’re better off with a different choice.

Errors

Excel can be modified by anyone, and it’s not always easy to keep accurate documentation of who did what and when they did it. Your errors can go unnoticed for quite a long time, and this can spell disaster if it sets you back.

Static

Excel, in particular, does not update in real-time, which makes coordination another issue. If you can’t track changes to the schedule as they happen, you may misinform your team and clients on the timeline. This spells disaster for your overall product-to-consumer pipeline.

How Can Fusion Operations Help With Production Planning?

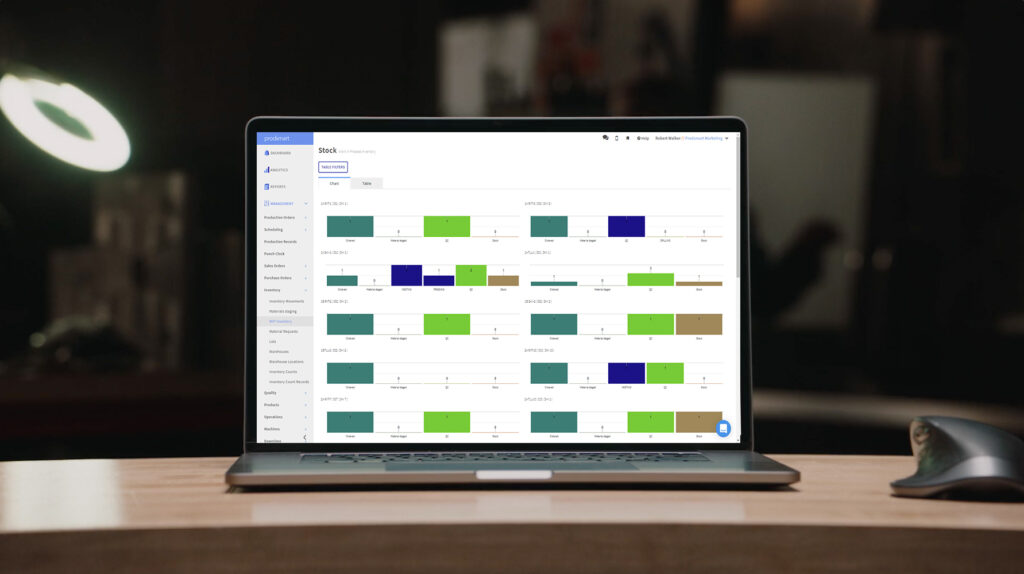

Fusion Operations equips you with the very best in manufacturing tracking and production management. We believe that proper planning and scheduling, and management keep teams happy and keep production moving forward.

Fusion Operations offers solutions to complex scheduling problems, ensuring that your data collection and management tools suit your unique needs. A production schedule should not feel slow or labor-intensive. Rather, it should be efficient and avoid errors when making immediate changes. We believe that no problem is too severe that smart, targeted solutions can’t fix.

Whether you’re a new, small team or an established brand looking to optimize your pipeline, Fusion Operations gives you the power to master your production schedule. With Fusion Operations, your pipeline will be efficient and expedient. Achieving happier workers, clients, and shareholders is possible with just a little planning and communication.

Are you ready to master your production planning? Fusion Operations is here to guide you every step of the way!