& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

5 min read

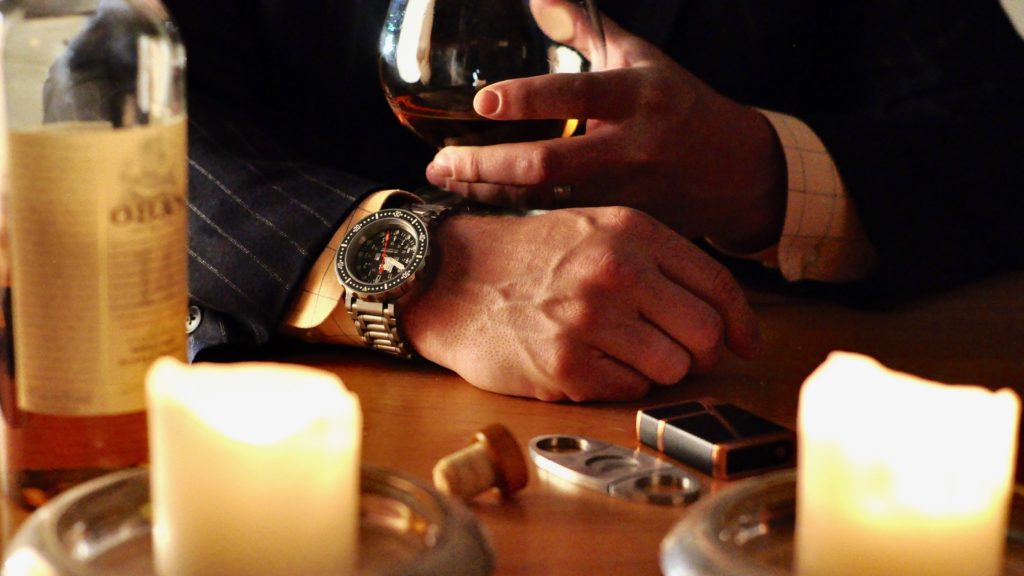

Andrew McLean is a rare breed of person, the kind of individual that you meet and you definitely don’t forget the experience. Andrew is an ex-independent contractor, running special projects all over the world, and as you can imagine, he’s been in some really varied landscapes, and so he’s kind of used to having gear that breaks. These days, Andrew does search and rescue operations in Arizona for an internationally certified mountain rescue group that works directly with a major law enforcement agency. While operating, one of the first and most common objects to break was always his watch.

Now, in the grand scheme of serving in the military, and as a special operative no less, your watch may not seem like the most important piece of gear, but it is in fact one of the most critical elements. The military still uses analogue watches for a number of applications, and Andrew tells me The military does still use high accuracy analog watches and stop watches. For example, B-52 flight crews time their take off go/no-go decision using a high precision watch (see Sēl’s article about B-52 and Apache Pilot Major Meredith Morris). GPS has cesium regulated timekeeping but batteries die and signals get interrupted so an instrument watch is still a very important piece of kit.

When I spoke to Andrew, the first thing he told me was that he started Sēl specifically to address the issues he was faced with while operating in the field as a contractor, and to marry that with something that is just totally epic that everyone would want one. One particular incident that stuck in his memory was looking down on the floor of a helicopter to see his watch lying there because the strap had broken, not exactly what you want to see in a high intensity work environment, particularly when it’s a critical piece of kit!

Now, there are hundreds of watch companies out there, all offering a slew of options, products, and application uses (just ask our resident watch nerd Keqing, he can tell you all about the nuances!) but only a few of those brands create something that would qualify as true military spec, and yet, as Andrew tells me “there’s nothing worse than being inserted in a remote and austere environment, only to find your watch cracked and is no longer operational”. So, enter Sēl, a new watch designed with extreme duty, spec-ops, and emergency service operators in mind, while still being something you would want to wear to all those black tie events you’re attending (we know you fancy, Fusion 360 community!)

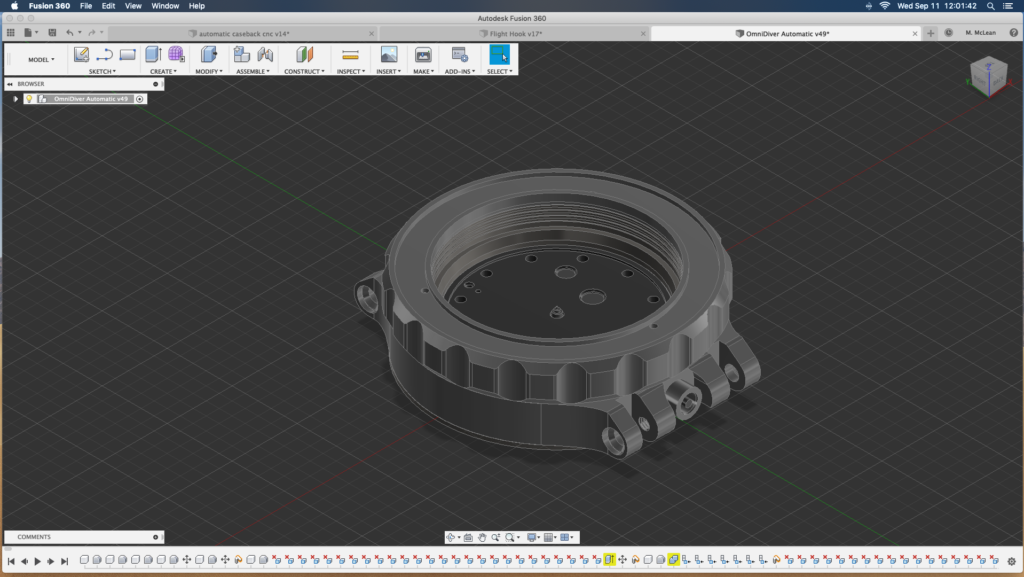

The watch designed by Andrew, has quite the spec list! Designed to withstand water pressure as deep as 6000m (that’s 19685 feet!!) it also features a specially engineered bezel top, and bracelet to minimize breakages, the crown is specifically designed not to dig into the back of your hand, and the bracelet and clasp can be easily adjusted without requiring specialist tools. That last one doesn’t sound all that innovative, but you need to remember that the target audience for Sēl are individuals dealing with the extreme, in those situations, your body naturally takes on and sheds weight rapidly, so you will want to adjust the bracelet fit for extended use comfort! Sounds pretty cool right? It doesn’t even end there! The watch is made up of 76 components, with a range of 360-420 parts depending on the configuration a customer orders.

Andrew even filed 4 patents for the product, all developed during the design phase, to ensure this was the best possible watch for extreme situations! On top of all that, the sapphire crystal – the “window” of the watch – is suspended in the watch case instead of being rigidly mounted which can reduce damage and shattering when knocked. I don’t know about you, but that’s the kind of small detail in a product that just makes me all warm and fuzzy inside. Andrew has even gone to the effort of offering the watch with two drive systems, High accuracy Quartz, or Automatic, depending on your applications and needs, say for example, if doing a HALO jump is on the “required skills” section of your job skills. In the quartz movement version, the quartz crystal which is the part that generates the pulse to keep time is thermo-compensated meaning the crystal oscillation frequency actually changes in different temperatures to keep the movement as accurate as possible (as in 10 seconds per year accurate!).

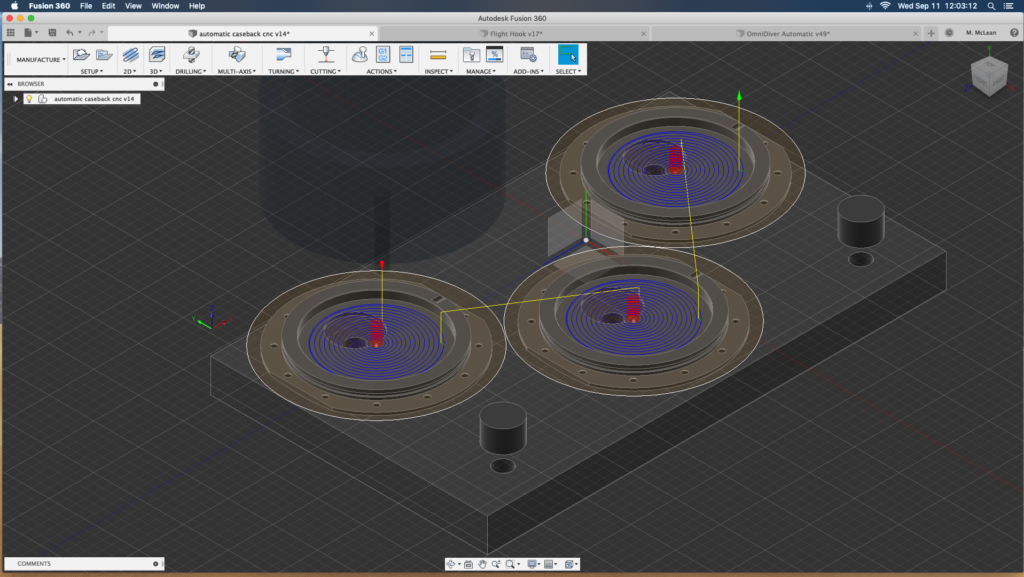

What really blew me away talking to Andrew about Sēl, was how a 3 person operation is able to comfortably ship and cater to an international audience! That’s a hell of a lot of work for 3 people, but only if you don’t know how to handle things! Because the Swiss make the best movements in the world, there’s no need to manufacture those yourself, and so Sēl has movements pre-manufactured and delivered to them on site where they modify them for final assembly. They machine and fabricate all of the other parts themselves, enabling the three of them to manufacture the watches fast and efficiently, without requiring a large workforce to support them!

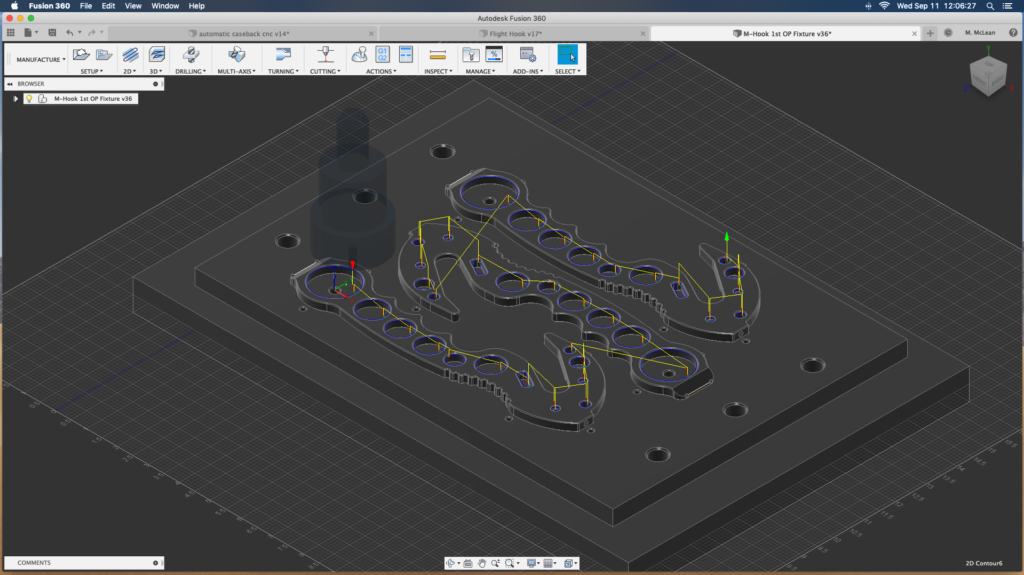

The watches, made of over 76 components, are machined in house using 6AL-4V titanium (I’ll leave a moment for that to sink in for the machinists, because that is 50 shades of cray right there) Andrew is a self taught Fusion 360 user, with a background in mechanical engineering, and his passion for building a better product is what brought Sēl to life, and they take their work so seriously, they even built their own hydrostatic testing chamber just for QA on their watches. If that doesn’t count as dedication to the craft, I’m not sure anything does. At this stage, Sēl is operating anything between 30 and 80 hours of machine time per week to meet demand, and is consistently growing their business.

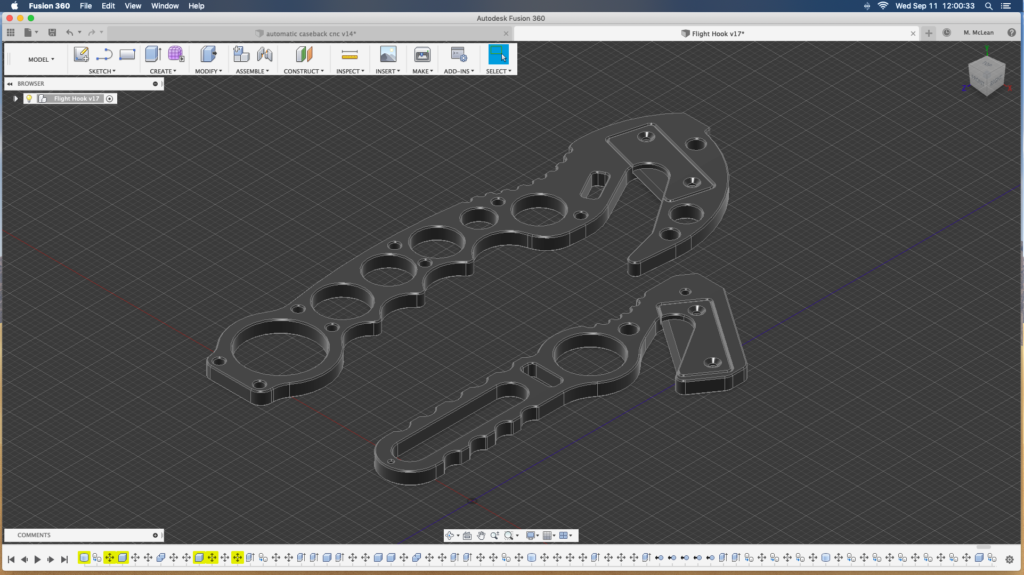

But it doesn’t stop there for Sēl, understanding and addressing the needs of people with extreme jobs is not easy, especially if you’ve never experienced those jobs before. Andrew’s unique perspective and ability to get to the root of the issues with the tools that first responders and military operatives deal with, enables him to make better things for them. Their latest products, two rescue tools, are designed to cut through ropes quickly, for fire fighters, the police, pilots, and anyone else who’s day job involves statements like “we need to rappel down this wall”

It really is quite incredible how much output three people can have, but I think Andrew puts it best, when I asked him if he could explain how they’ve been able to work so fast! “[with Fusion 360] I could model something, go to CAM, and be machining in 10 minutes”

If you’re interested in Sēl, check out their website here, more with Sēl coming soon!

By clicking subscribe, I agree to receive the Fusion newsletter and acknowledge the Autodesk Privacy Statement.

Success!

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.