Learn what to look for in 5-axis CNC mill machines for mold making…work-envelope size, axis limits, controller features, and more. Choose the right CNC mill and boost productivity.

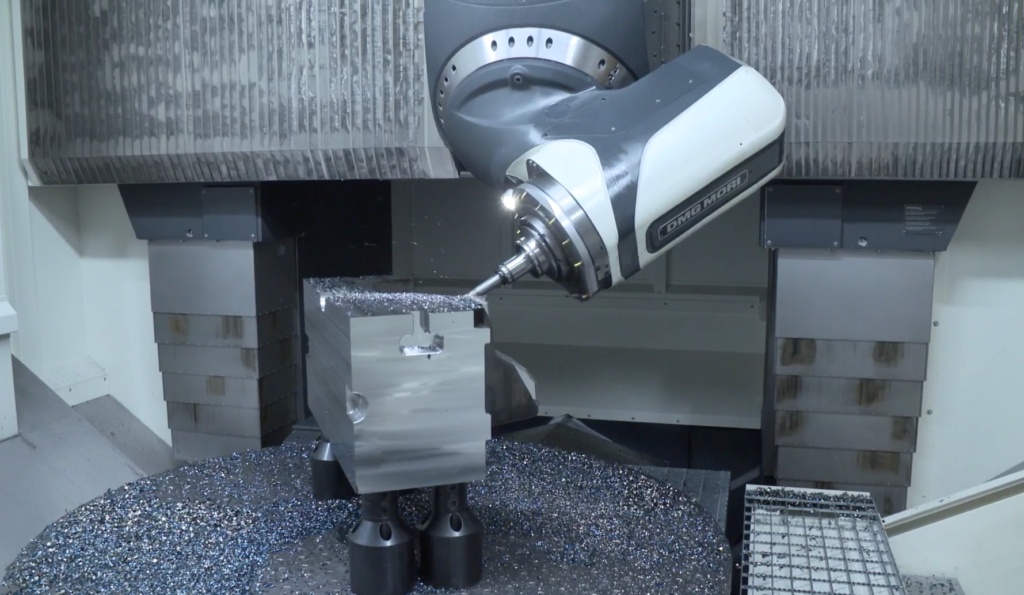

In the past, 5-axis CNC mills were built and marketed for the domain of aerospace and power-generation manufacturers, but today’s CNC mill machines are increasingly essential for mold makers.

So, what should you look for when you shop for a 5-axis CNC mill for mold making, and how do competing CNC mill machines stack up on accuracy, speed, and rigidity?

When discussing 5-axis machining, it is important to differentiate the 3+2 axis and simultaneous 5-axis machining differences, because each mode places unique demands on the CNC mill machine and its controller.

Most 5-axis mills used in mold making are either A&C or B&C in configuration. Selecting the right CNC mill machine style depends on part geometry and throughput goals.

5-Axis CNC Advantages

There are many advantages to implementing 5-axis machining for mold making, a few of the more common ones are:

Use Fewer Setups

5-axis machining allows for milling complex shapes with one setup versus multiple setups to accommodate the machine, spindle, and tooling. This tightens tolerances between features, especially for holes or features that are at compound angles.

This can also reduce overall setup time. A quick reorientation of the machine takes mere seconds while switching setups can take significantly longer – on the order of hours depending on complexity and part requirements. 5-axis machines can save valuable time, decreasing job time and winning you more business.

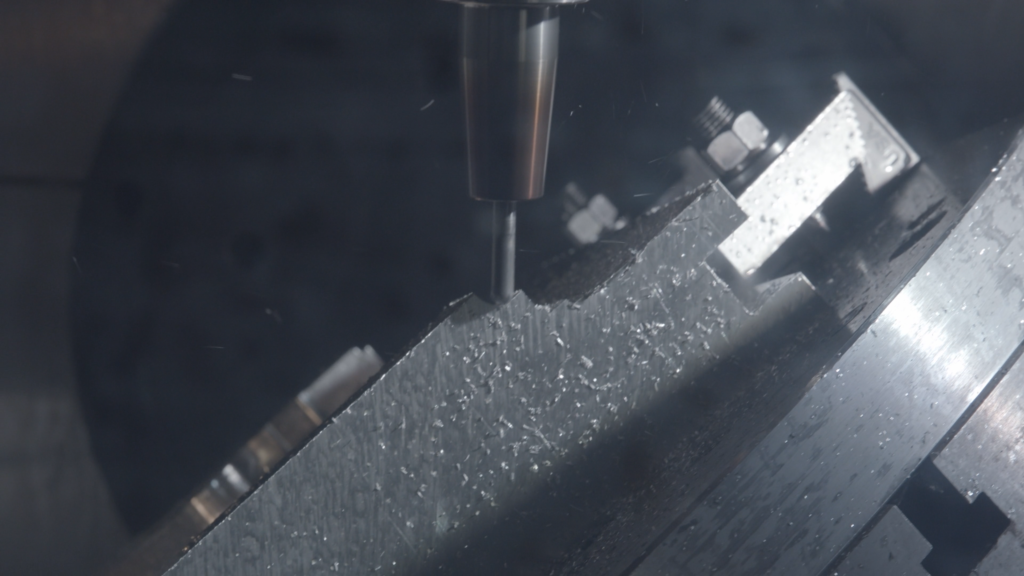

Finish with Shorter Cutters

Full 5-axis capabilities can tilt the tool axis around the part, allowing shorter cutters and smaller L/D (length to diameter) ratios. This helps reduce tool vibration and deflection to provide a superior surface finish.

Mill Deeper Areas

Often deep areas of a part that are difficult to reach from straight in the Z-axis can be milled by rotating the tool axis and performing a 3+2 or simultaneous 5-axis operation.

Save Time and Money

Using shorter cutters often allows for faster feed rates due to reduced deflection and vibration. 5-axis CNC milling of deep areas and ribs can reduce the need for slower EDM operations, reducing time to ship. Together they save time and money in mold making.

Overall, 5-axis machining can help you deliver superior parts with tighter tolerances across key features in less time, so your business can stay competitive.

3+2 Versus Simultaneous 5-Axis

When discussing 5-axis machining, it is important to differentiate the 3+2 axis and simultaneous 5-axis machining differences. Generally, a 5-axis CNC mill will have three linear axes: X, Y, and Z. They also will have two rotating axes, either A&B, A&C, or B&C. The rotating axis corresponds to the linear axis. For example, the rotational A-axis rotates around the linear X-axis. The B-axis rotates around Y, and the C-axis rotates around Z. Most 5-axis mills used in mold making are either A&C or B&C in configuration.

3+2 Axis Machining

The machine rotates into position, using the two rotational axes, then performs a traditional 3-axis cut. It rotates first, then cuts, but not at the same time. Think of this as setting any tool vector for a temporary work plane and performing a 3-axis cut from there. Since you are setting a workplace, traditional canned cycles, like drilling, can usually be used during 3+2 axis machining.

3+2 axis machining has the advantage of simpler programming. Fusion 360 makes 3+2 operations especially easy—there is simply a checkbox in every milling operation that allows you to reorient the tool using a quick geometry selection, graphical handles, or aligning to the current view. This streamlined programming approach makes it easy to get the most out of your machine.

5-Axis Simultaneous Machining

In this mode, the rotation axes can be used at the same time as the linear axes. That is, all five of the axes can be used simultaneously. Rotating and milling at the same time. Continual motion means the tool stays in contact with the part and possibly has fewer retracts or areas to blend.

Fusion also offers simultaneous 5-axis operations to increase your capacity for complex parts and use your machines to their fullest potential.

It is important to note that most 5-axis machines are actually performing 3+2 axis milling around 80 percent (or more!) of the time in mold making. Simultaneous machining is reserved for certain unique applications—typically when 3+2 won’t cut it.

Basic Mill Differences

There are many different styles of 5-axis CNC mill designs. For this article, we will simplify it into two main groups; rotating table or rotating head.

Rotating table designs are where the part is mounted onto a table that rotates, typically with a C-axis movement. Either the table performs the other rotation, as in the case of a trunnion, or the spindle has one axis of rotation to complete a 5-axis machine.

Rotating head designs typically use some knuckle the spindle is mounted into. The knuckle normally allows for two axes of rotation, typically A&C or sometimes, but less commonly, B&C.

Some advantages to rotating table designs are:

- Higher rigidity than rotating head designs

- Greater speed and performance than rotating head designs

Some advantages to rotating head designs are:

- Larger work envelopes and heavier parts than rotating table designs

- More versatility with fixturing and multiple parts than rotating table designs

No matter what configuration you decide to use, Fusion programs each in the same way to keep programming straightforward. We even offer a library of fast, free, and fully customizable post processors so you can tailor your G-code to your needs and get parts done right.

Size of Work Area

One of the biggest considerations when purchasing a 5-axis CNC mill is the size of the work envelope. One common mistake is buying too small of a mill the first time around.

Just like in 3-axis machining, the Z travel of the machine is important when machining cavities. You need enough Z-travel to fit the part and long tools to retract out of the part. Additional clearance in a 5-axis machine for tool retracts is necessary all-around your part.

While shopping, when you consider a 5-axis machine, consider the largest part you would use on the machine, and add your longest tool to the dimensions all around the part. This will help to ensure you buy a mill with sufficient clearance.

Axis Limitations

When considering a 5-axis mill, take any limitations on the rotational axes into consideration. Limits in the rotation will limit how much of a part you can mill in 5-axis. If you need to mill parts with backdraft conditions, make sure your 5-axis CNC mill has enough rotation capability to accomplish this.

Also, if using a typical 5-axis mill, find out if the C-Axis has any limits or not. An unlimited C-axis allows you to continually spin the part while milling it. Think of an object like a soda bottle. With a continuous C-axis, you can keep spinning the bottle while milling it from top to bottom, backdraft areas, and all.

Machines with limits to the C-axis rotation will be forced to retract away from the part, unwind the axis, re-approach the part, and continue milling. These unwind movements can waste valuable milling time with movements in the air simply because of limits.

Controller

Without the milling machine controller, all you have is a big hunk of expensive metal. Its job is to take data from the encoder on the linear and rotational axes and control what the motors do next.

In simultaneous 5-axes, not only does the controller have to accurately synchronize the X, Y, and Z linear movements, but it has to manage the rotational axes as well. This is more difficult as speeds increase when components move farther away from the center of rotation.

Not all 5-axis controllers are created equal. Some do the synchronization better than others—some slow down the milling process when performing simultaneous 5-axis. When shopping for a 5-axis CNC mill, it’s important to look at the realistic speeds available in simultaneous 5-axis mode.

One other thing to consider when purchasing a 5-axis CNC mill is how well does the controller set workplaces for 3+2 axis machining? Are all canned cycles available at any inclination? What is required in post-processed output to manage thins?

Another consideration is whether the controller has a way of setting RTCP, Rotation Tool Center Point? This is where the controller knows the origin of the part in relation to the center of rotations and can accurately calculate necessary movements for the programmed part. Some form of RTCP (sometimes called TCPM) is normally using simultaneous 5-axis to finish mold parts.

Tool Holding

When using high-performance spindles and tooling, the tool holder system can positively or negatively affect the overall rigidity. Some tool holder clamping systems clamp from the outside of the holder with inward pressure. Other systems clamp from the inside of the holder with outward force. The latter systems, holding from the inside with outward force, are aided by the centripetal force of the rotations from high-speed spindles.

Linear Ways

Most CNC milling machines use ball screws, which include ball bearings to reduce friction, to control movement. Some recent developments in CNC machines are to replace the motor and ball screw with a linear motor. Costs for machines equipped with linear motors will typically be higher. However, on average, they can provide higher acceleration levels, higher precision, and smoother operation.

It is important to note that those advantages are compared to mid-level 5-axis CNC mills. High-end 5-axis mills with more robust encoders, scales, screws, and motors provide the same speeds and precisions available from linear motors.

CAD Files

When performing 5-axis machining, you will want to simulate and verify your CNC programs before running them on the mill. As you start rotating the part or head, the chances for a machine to part collision increases.

Accurate simulations start with accurate 3D CAD data of the 5-axis CNC mill. Without an accurate representation of the machine, the simulation is, at best, an estimation. This includes the spindle, table, and all the parts that make it rotate, whatever style it is.

Some machine vendors provide CAD files of their mills, some charge for it, and others will not provide them at all. Whether the CAD files are provided, bought, or you design them yourself, you will need to verify the 3D data against the actual machine dimensions to make sure they are accurate.

Adding 5-axis milling to mold making has many advantages and can improve finishes, reduce time to ship, and reduce the need for EDM operations.

When considering 5-axis CNC mill, consider going up one size than you think you need. Verify the RTCP capabilities for simultaneous 5-axis machining. Check the simplicity of using different temporary work planes for 3+2 axis machining. Consider higher quality, more robust components for higher speeds, accuracy, and finish quality.

Set on buying a 5-axis CNC mill? Learn more about how to maximize your machine with Fusion.