(v.2.0. 20508) – October 31, 2024

- We fixed an issue where exporting to STL and other cloud-related formats did not complete and caused Fusion to freeze.

- We fixed an issue where the data panel was not syncing and updating correctly for certain users.

- We fixed issues where editable documents for personal users were getting stuck in the data panel.

(v.2.0.20494) – October 21, 2024

Data Panel:

- We fixed a variety problems where the data panel was wrongly assuming that Fusion was in the offline mode and was not showing all the relevant panel options.

Installer:

- We fixed an issue where live updates were leaving behind the entire folder of the older versions.

Save As Mesh:

- We fixed a problem, that occured in the September update where “save as mesh” was not correctly remembering the selections made on the previous use of the command.

Manufacturing:

- We fixed a problem where Retract moves were not being defined and respected in the Heights dialog irrespective of their WCS origin placement.

- We fixed an issue impacting users computing toolpaths on meshes with face groups.

(v.2.0.20476) – October 9, 2024

Manufacturing

- We fixed a variety of crash issues occurring within the CAM environment.

- We fixed an issue within the Manufacturing environment where the Drill toolpath depth was exceeding when in point selection mode.

(v.2.0.20460) – October 1, 2024

Design

- We fixed various crash issue occurring within the Sketch and modeling environments.

Manufacturing

- We fixed a crash issue occurring within the Manufacturing environment.

- We swapped the order of the model and fixture groups in the in machine avoid table so that fixture surfaces will not be removed from the model group.

- We fixed an issue where Toolpaths would permanently gain an error upon the Manufacturing extension disabling.

- We fixed an issue causing Shaft and Holder options to not work as expected in multi-axis Flat toolpaths

Electronics

- We fixed an issue where Net-class rules cache was no longer updating properly when using the In Net Classes scope.

- We fixed an issue causing Custom rules to not work as expected when using differential pairs.

- We fixed an issue where exporting multiple images in PDF from the CAM Processor would only show you one view.

Simulation

- We fixed an issue causing meshing discrepancies between cloud and local meshing.

General

- We fixed an issue where certain add-ins would cause Fusion to crash on startup.

- We fixed an issue where Fusion was not sending parts to slicer via print utility if the slicer was already open in Mac OS.

(v.2.0.20256) – September 17, 2024

Table of Contents

- Highlights

- Upcoming Changes

- Data Management

- Usability

- Performance

- Design

- Drawings

- Electronics

- Generative Design and Simulation

- Manufacturing

- APIs

- Customer Reported Fixes

- Join the Insider Program

Highlights

The September software update for Fusion is here, bringing powerful new features and improvements designed to enhance your design and engineering workflows. From the addition of Offset of Offset, to more intuitive user interfaces, highly requested fixes, and powerful enhancements that will streamline your processes and boost productivity we can’t wait to share everything with you. Let’s dive into the specifics and see how these new capabilities can elevate your workflows.

Usability and Data Management

- New Onboarding Experience

- Fusion No Longer Appears Over Other Apps on macOS

- Improved File Actions in Home Tab

- “Show in Location” option added to the Design and Drawing tree

- Various Performance Enhancements

Design

- New Offset of Offset

- New Two Sides Offset

- New Ability to Change a Parameter Name on the Fly

- New Configure Joint Snap and Flip aspects to control component location across configurations

- New Configure non-parametric aspects in Thread features

- New Ground to Parent and Joint Assembly Workflow Update

Drawings

- New Drawing Automation: Default Recipe by Sheet Type

- New Delimiter Support

Electronics

- New DRC Engine and UI

- New Ability to Import Electronic Designs from KiCad version 7 and 8 to native Fusion format

Simulation and Generative Design

- New Copy Study in Configured Designs for Simulation

- Shape Optimization Criteria now has an “Auto” option for Target Mass in Simulation

- New Linear Global Load and Angular Global Load in Generative Design

- Copy Study now available in Configured Designs for Generative Design

Manufacturing

- New Machine Avoid Tools for Toolpaths

- New Additive Machines and Print Settings

- Improved Spun Profile Calculation

- Improved Silhouette Detection for Arrange and Nesting to Prevent Part Overlaps

- New Automated Arrange

- New Import CAM data from Linked Designs

- New Vendor Tools Libraries

Live with the Experts: What’s New in the September 2024 Release

Want to learn more about all the updates coming to Fusion this May? Join us on Thursday, September 26, 2024 for a LIVE webinar where we’ll dive into improvements around flexibility, control, and programming efficiency, show off some tips & tricks, and open up the floor for LIVE Q&A. Looking forward to seeing you there! `

Register for 8am PST | 11am EST | 4pm BST

Autodesk University is Just Around the Corner

Autodesk University is quickly approaching and we can’t wait to see you all in person in San Diego on October 15-17.

For those of you attending we highly encourage you check out all the amazing classes, events, and community meetups. Come find us in the Expo hall and build a product in our hands-on, Fusion factory experience.

The Senior Director of Fusion Product Management, Daniel Graham is putting on a can’t miss Roadmap class for all the upcoming features transforming how we design, engineer, and manufacture:

Fusion Roadmap: Design, Engineering, & Manufacturing

If you’re still playing catchup on the massive amount of updates and upgrades we’ve added to Fusion over the past year, check out DE1130 – Autodesk Fusion, a year in review.

Upcoming Changes

Important OS support information after March 2025

After March 2025 Fusion will no longer fully support macOS 12 Monterey. To continue developing Fusion with the latest advancements, we must stay current and phase out support for older OS versions. We understand that this change may require some time for you to adjust. That’s why we are letting you know now, so you have plenty of time to update your OS to the latest version.

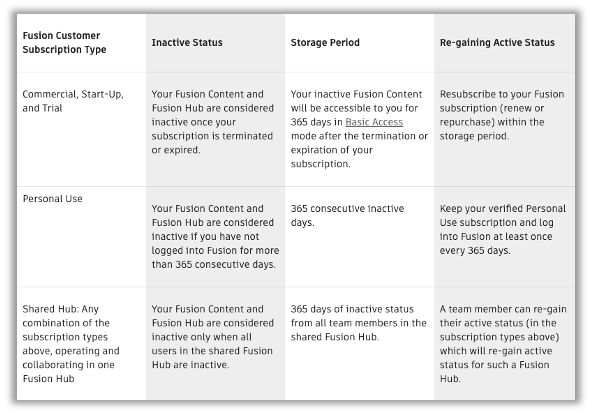

New Standard regarding your Fusion Content

In August 2024, a new Fusion Content Storage Standard was introduced to protect and minimize how long we store your Fusion Content even after you are no longer subscribing to or using Fusion. To help ease the transition into this new Standard, the accessibility to any inactive Fusion Hub that has reached the end of the relevant storage period won’t be impacted until, at the earliest, August 2025. Learn more in the FAQ here.

Data Management

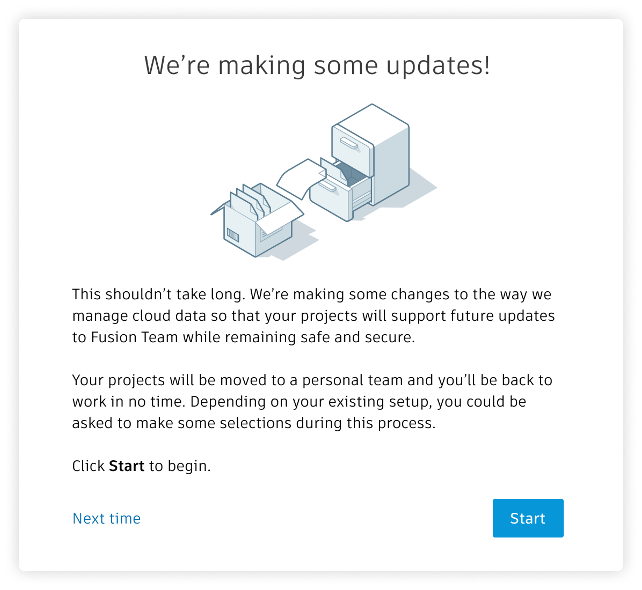

Moving to Fully Featured Hubs in Autodesk Fusion

What’s changing?

Autodesk is making some changes to the way we manage cloud data so that your projects will support future updates to your Fusion Hub. Starting soon, you can upgrade your Fusion Single User Storage to take advantage of a fully featured Fusion Hub.

What actions do I need to take?

If you do not have a single user storage hub, then there is no action to take, and you are already using a Fusion Hub.

If you’re using single user storage you’ll see the notification appear in Fusion when it’s time to upgrade.

Want to learn more about this change? Check out this support article for more information regarding the change.

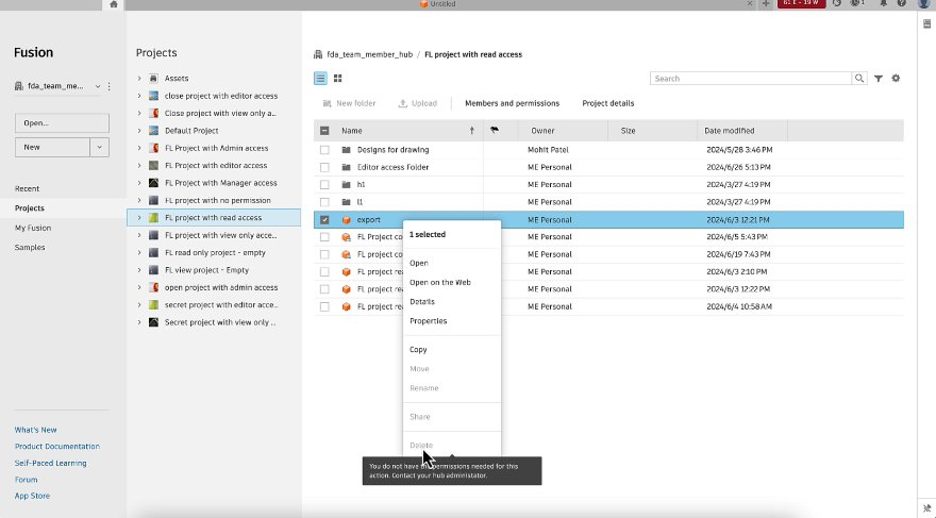

Improved File Actions in Home tab

In the Fusion Home tab, the user experience for handling file, folder, and project related actions has been improved. Now we consider your permissions within a certain project and folder and show only the available commands while keeping others greyed out. When hovering over an unavailable action you will be notified about the lack of permissions and encouraged to reach out to the administrator to adjust your role.

Previously, all actions seemed available and but upon clicking on an action, there was a message telling you to check the internet connection and to try again later.

“Show in Location” option added to the Design and Drawing tree

In the Design or Drawing workspace, you can now navigate to the project and folder location of the design or drawing in the Data panel. When right-clicking on a design or drawing in the design or drawing tree, the “Show in Location” option will now open the Data panel and navigate you to the file location within the project and folder structure.

Usability

A New Look for Fusion Loading Screen

Have you ever been blinded by Fusion’s bright white loading screen when working in the dark? If so you’re in luck because as of this update we turned the lights off for Fusion’s loading screen.

Fusion No Longer Appears Over Other Applications on macOS

We are excited to announce that we have addressed the major root causes of the Browser and Comments frames popping on top of other applications while Fusion is in the background (especially at application startup). In addition, these improvements should improve macOS’s handling of Fusion windows when entering Fullscreen with macOS Spaces virtual desktops – individual windows and UI elements should no longer erroneously create their own blank virtual desktops separate from the main Fusion window frame.

Thank you to the users who provided steps to help reproduce and diagnose this longstanding Mac client issue.

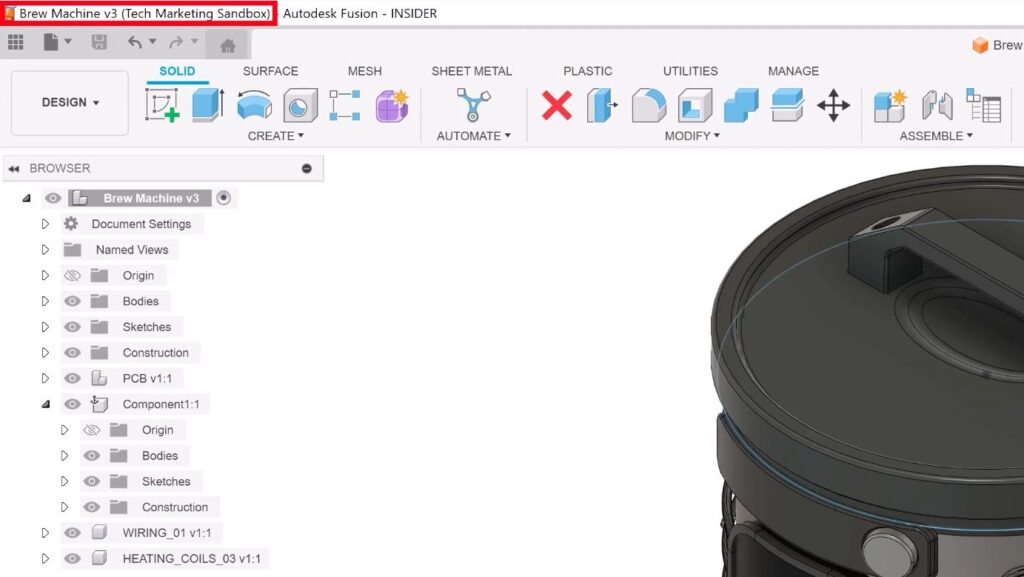

Improved Active Document Tab Visibility in the Application Title Bar

Fusion now displays the current document tab name and active Fusion hub in the application title bar, making it easier to tell which document is open at a glance. This should be especially helpful for our Electronics users, who frequently work with multiple Fusion windows in the taskbar/dock.

New Splash Screen in Windows taskbar

Previously we added status text to the Fusion splash screen to help you visualize the state of Fusion’s startup. However, if you dismissed this screen behind another application, it was difficult to keep track of.

The Splash Screen itself now appears in the Windows taskbar so that you can quickly bring it back into focus to check status, if needed.

In addition to displaying the Splash Screen in the Windows taskbar, the taskbar node itself will now echo the status text and current progress bar state of the Splash Screen, making it easier to track Fusion’s initialization progress while the application is in the background.

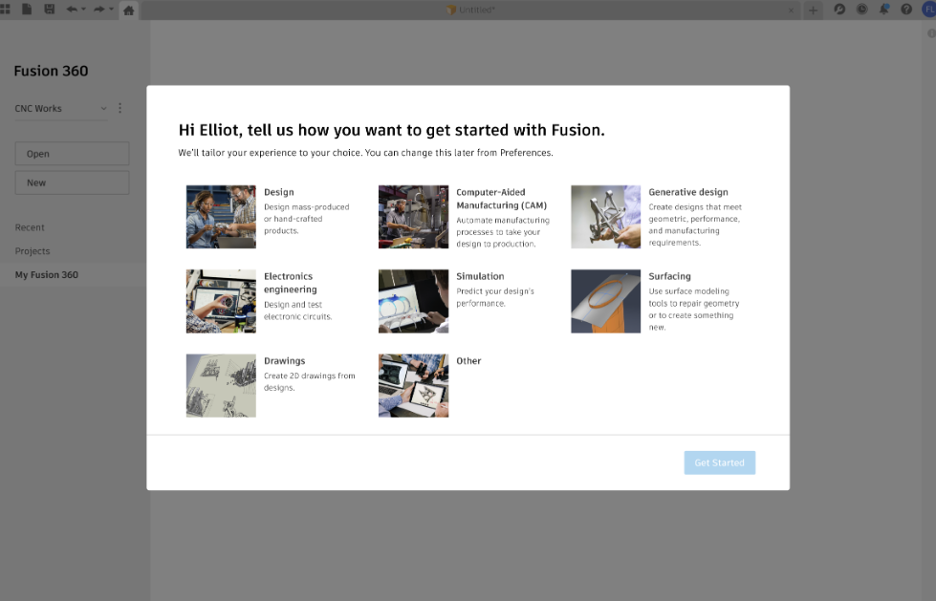

Exciting Updates to Your Fusion Onboarding Experience

We are excited to announce the improvements to Fusion’s onboarding experience. The improvements are designed to be more personalized based on your intent for using the product.

The improved experience features a more targeted intent screen that aligns with our three core design personas: Design, Electronics, and Manufacturing. This enhancement acknowledges the diverse needs of our user base, helping you select intents that closely match your goals for using the product, leading to a more efficient workflow.

What’s in it for you?

When you choose your intent, you now receive tailored recommendations for first tasks that are specific to your selection. This guidance offers a clearer understanding of the tasks associated with your intent, enhancing your clarity about the next steps in your design process, letting you focus on the most relevant actions.

Additionally, we have introduced the ability to change your intent directly from the ‘My Fusion’ page in the App Home. This prominent location allows you to easily adapt your tasks to meet your evolving needs without the hassle of navigating through multiple menus.

With these enhancements, our aim is to help you navigate Fusion more efficiently and effectively, empowering you to work smarter and achieve your goals faster. We can’t wait for you to experience these improvements!

Performance

With every update, our team is dedicated to making Fusion faster and better than ever. We invest a lot in performance improvements because we know how important it is for you. We’re committed to enhancing Fusion’s speed and ease of use with each release. So, let’s dive into some standout features from our August release that we think you’ll love:

- Create Large Component Instances Faster: Experience up to 17.8x improvement when creating a large number of components using the 3D Printing Essentials add-in.

- Speed Up Opening 3MF Files: Open your 3D Manufacturing files (3MF) in Fusion up to 6.3x faster.

- Enhance Rectangular Pattern Performance: Enjoy approximately 39% faster performance when creating Rectangular Patterns with some assembly components.

- Quickly Select Large Numbers of Faces: Use a selection set to select a large number of faces up to 15.3x faster.

- Better Edge Selection for Patching: Notice improved performance in edge selection when using the Surface → Patch command.

- Property Panel Loading Time Improvement: We’ve improved the loading time for the Fusion property panel, and we’re actively working on specific areas to fully optimize and enhance loading times for an even better user experience.

Design

Form Bevel Improvements: Width and Crown Settings

Design > Form > Modify > Bevel Edge

Bevel now has two modes that let you define the bevel’s size in different ways. In addition to Relative Offset, there is a new Bevel Width option.

You can also specify a Crown value to adjust the flatness or curvature of the bevel’s surface. Specify a value between 0 and 2 for a rounded bevel, 0 for a flat bevel, or 2 for a sharp bevel.

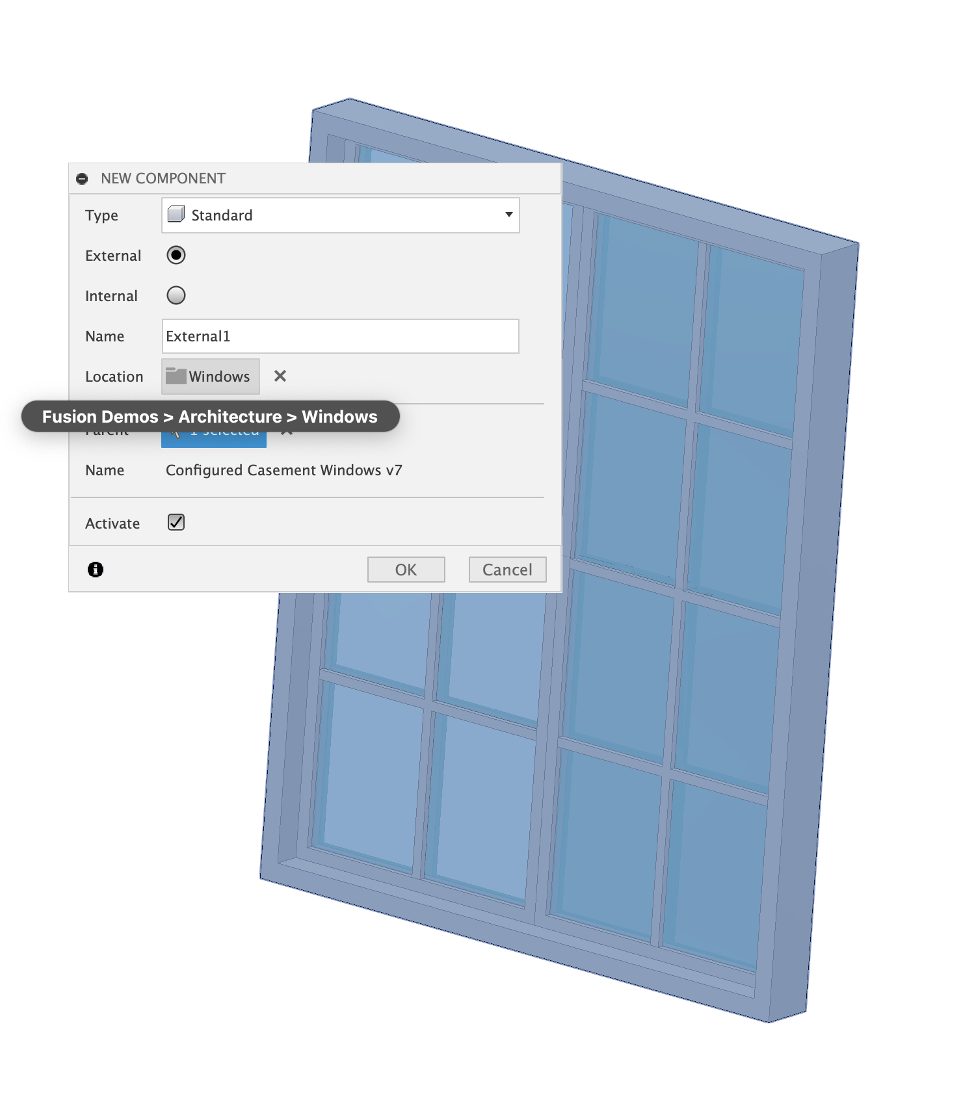

Create New Component Dialog Improvements

Newly created external components now automatically save in the same location as their parent, streamlining workflows and keeping projects neatly organized.

If the parent component has not been saved yet, then the default location will match the active project and folder in the Data Panel. Additionally, the selected parent component name will now be prominently displayed in the dialog under the parent selection button.

Learn more about Components.

Ground To Parent and Joint Assembly Workflow Update

When testing out assembly workflows with Ground To Parent and Joint creation, we received feedback that could be tedious when trying to create a joint and that some found that they needed to unground a component to avoid assembly conflicts.

Now when you create a joint, if the first component you select is grounded to parent, then it will be automatically ungrounded. This will help streamline joint creation and assembly workflows.

Want to be a part of the conversation surrounding the development of Fusion? Join the Insider Program for an early look at what’s coming to Fusion next.

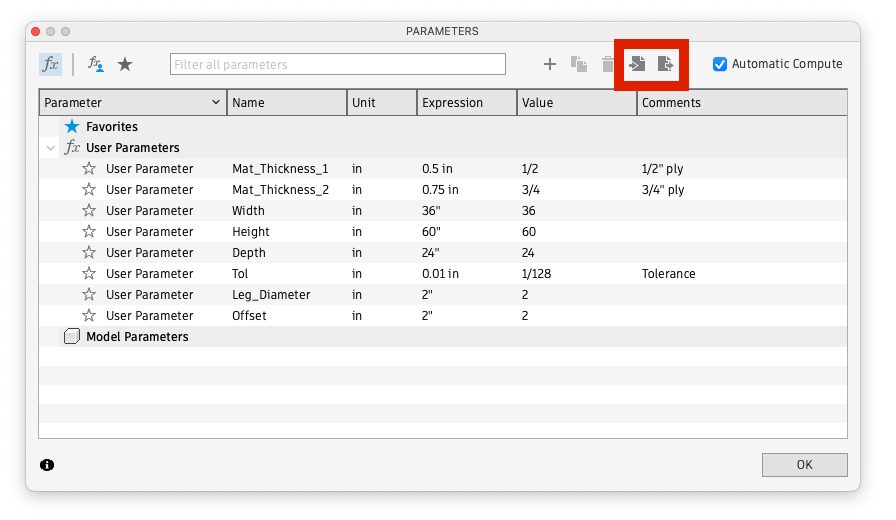

Parameter Improvements

Import and Export User Parameters

Design > Modify > Change Parameters > Import Parameters

Design > Modify > Change Parameters > Export Parameters

You can now export and import User Parameters in the design workspace. This improvement makes it easier for you to reuse parameters across different designs and to share them with collaborators.

Learn how to Import and Export Parameters.

Change a Parameter Name on the Fly

Previously, you could not change the parameter name on the fly without also changing the parameter’s value at the same time. We’ve fixed this so you can now modify the parameter on the fly independently from its value.

Offset Enhancements

New Offset of Offset

We are so excited to announce the release of Offset of Offset. This highly requested new feature is available within the same Offset command in the Sketch module. The goal is to allow you to create offset of an offset child. You now don’t have to create multiple offsets from the single parent. Offset dimension and constraint will be applied with respect to selected offset child.

Note: All offset related enhancements are meant for the newly created offset constraints from September release onward. Legacy offset constraint and geometry will work as they were.

New Two Sides Offset

This new feature in the existing Offset command will allow you to create offset geometries on either side of the selected geometry at the same distance. Additionally, we are providing an option to link or not to link two offset dimensions. In this case the tool will automatically make one of the offsets the primary/driving offset and the second offset will have a value that is the negative of the primary offset. I.e. Second Offset Value = – Primary Offset Value. This linking won’t work in Direct Modeling mode because the second value/parameter is driven by the primary’s value/parameter and Direct Modeling doesn’t support parameters.

New Blocking Topology Change in Offset

This is a new feature introduced in existing offset command, where you will now have control over the topology change of the offset child while creating the offset. This option is stored as part of the offset constraint so, a later change in the geometry or parameters that will cause topology change in the offset child will not be allowed. In cases where topology is changed you will see a notification informing you of the change.

Please note that once an offset is created its “Topology change” attribute or property cannot be changed during edit offset workflow.

Retain Offset Constraint on Deleting a Geometry

You are now able to retain offset constraints when deleting a geometry. This means that Offset Constraints will no longer get deleted if a geometry/curve from parent of child geometry is deleted. We will try to retain offset constraint and offset dimension as far as possible.

Correct Updating of Offset from a Projected Geometry

With current Offset enhancements, we fixed an issue which was reported by multiple customers. The issue was that suppose user has projected a body or a geometry and created an offset geometry using it. Now if the original body/geometry is changed parametrically the offset would not get updated. This is now fixed, if the original geometry changes the subsequent changes will be seen in the offset.

Configurations Enhancements

Configure Joint Snap and Flip Aspects to Control Component Location Across Configurations

Up until now, to configure the placement of components in an assembly, you had to create multiple joint instances and suppress all but the relevant one in each configuration. This creates a lot of redundant Joint features and can quickly complicate your configuration table.

With the September release, you can now simplify this scenario by configuring the Snap and Flip aspects for any Joint feature in an assembly.

- Check the aspects to add them as columns in the configuration table

- Add and name new Snaps to the list

- Select a different Snap for each configuration

- Flip the Joint for any configuration that needs it

Right-click any Joint feature in the timeline and choose Configure to access these new configurable aspects.

Learn more about Joint Snap and Flip

Configure Non-Parametric Aspects in Thread Features

As we continue to expand the aspects you can configure, the next addition includes several non-parametric aspects of Thread features:

- Modeled

- Full Length

- Thread Type

- Size

- Designation

- Class

- Direction

Are there more aspects you need to configure that aren’t available yet? Let us know!

Learn more about Configurable Aspects

Performance Improvement for Inserting or Switching Configurations

When the configuration table is large, it can take a long time to insert or switch configurations when inside another design or drawing. With this release, you should see a significant reduction in time it takes to insert a configuration or switch from one to another.

Drawings

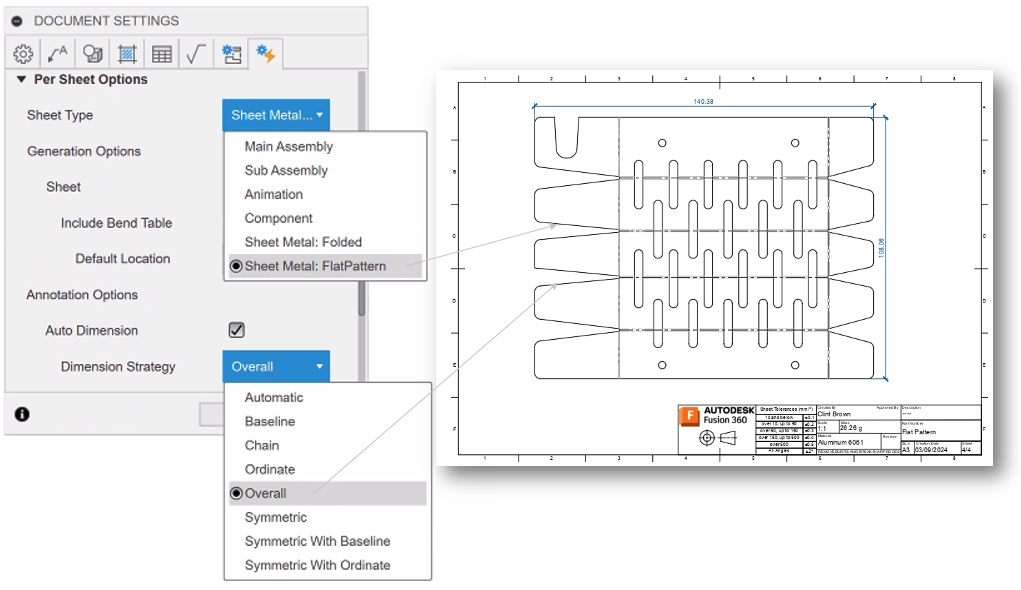

New Default Recipe by Sheet Type for Drawings Automation

Default dimensioning strategies can now be set up in your drawing template. When you create, or edit a drawing template, you can now choose a default dimensioning strategy for each sheet type.

In the Document Settings of your drawing template, on the Automation Settings tab, you can now set your preferred dimensioning strategy of these sheet types:

- Assembly

- Component

- Folded Component

- Flat Pattern

- Storyboard

As an example, you can set this up, so that Sheet Metal components automatically get Ordinate Dimensioning when you use Automatic Drawings. This makes your workflow smoother and more efficient by adding another layer of control to your automations.

Learn more about Drawings Automation.

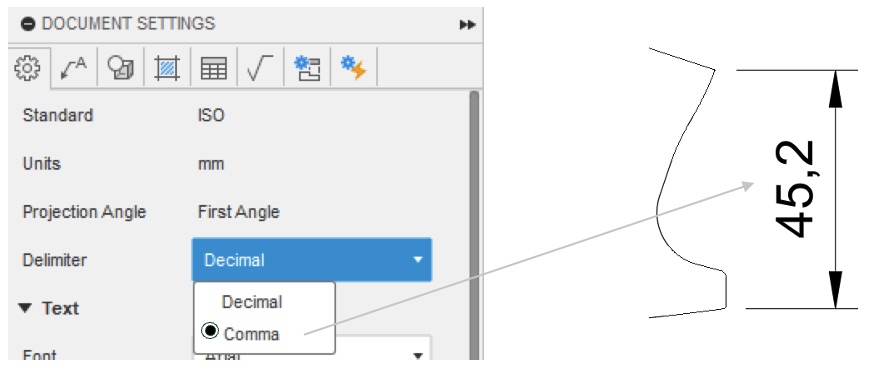

New Delimiter Support

You can now specify whether a comma or full stop is used to specify the decimal delimiter of a number. Making your drawing standard, better suited to your region. For example, you can choose between: 2.1mm or 2,1mm.

Learn more about Document Settings reference in the Drawing workspace.

Electronics

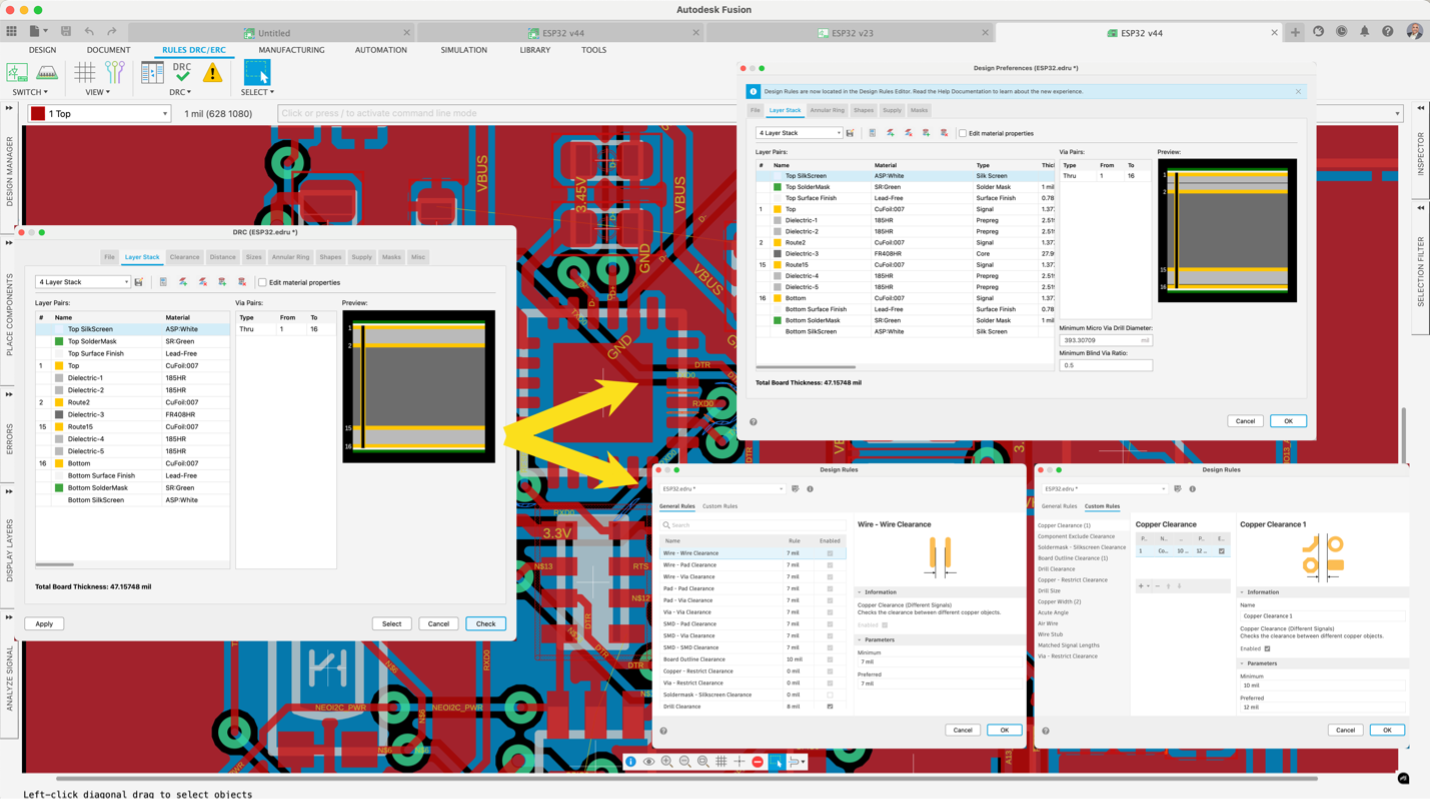

New Design Rules Engine and New UI

Fusion Electronics now has a more advanced DRC interface, and the new engine allows you to specify custom rules and preference scopes. The wide range of rules and scope options preferences empowers you to meet even the most stringent manufacturing and design requirements, making designing complex PCBs even easier. Set width, clearances, width preference per layer, signal, or component, and much more early in the design stage to meet your critical signal integrity design needs, making it easier to complete your designs for prototype and manufacturing sooner. Default legacy rules (DRU) can be added, removed, and edited using the new Design Preference Interface. We assure you that your current DRC preferences setup are fully compatible with the new engine, so you will pick up where you left off.

Learn more about Design Rules for Electronics.

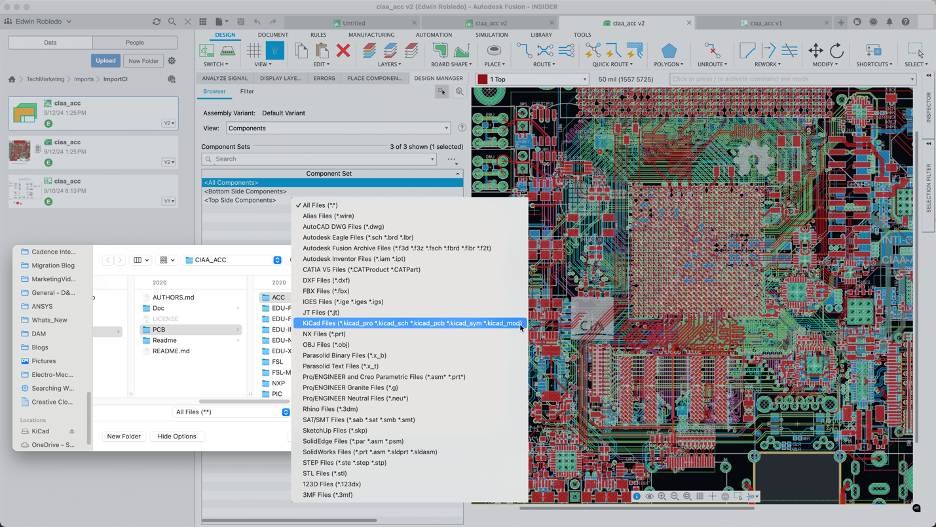

New KiCad Importer

Autodesk Fusion Electronics’ developing team has extended our design compatibility features. We recognize that seamless teamwork is essential for progress. We are thrilled to introduce our latest update with enhanced importing features. You can now import your Electronic Schematic, PCB, and Libraries from KiCAD into the Fusion workspace. This empowers you to continue your work from where you left off, but now, with the added advantage of utilizing Fusions’ comprehensive electromechanical platform and electronic design capabilities.

Learn more about the KiCad Importer.

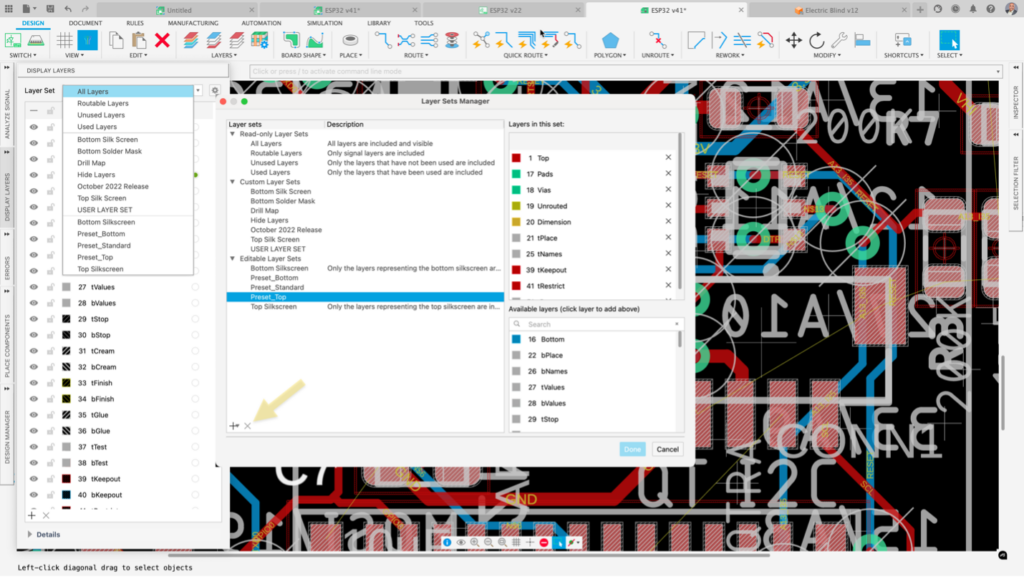

Make Layer Set Presets Editable and Disallow Delete

In circuit design, the functionality of every layer is critical. Seamlessly switching between layer views is essential, as it allows you to focus on the specific information relevant to your current design stage. For example, when routing on the top layer, temporarily hiding all other layers makes it easier to identify the best path for your signal. In this update we improved your experience by allowing for Layer Set Presets to be edited and disallow the deletion of Default

Editable layer sets.

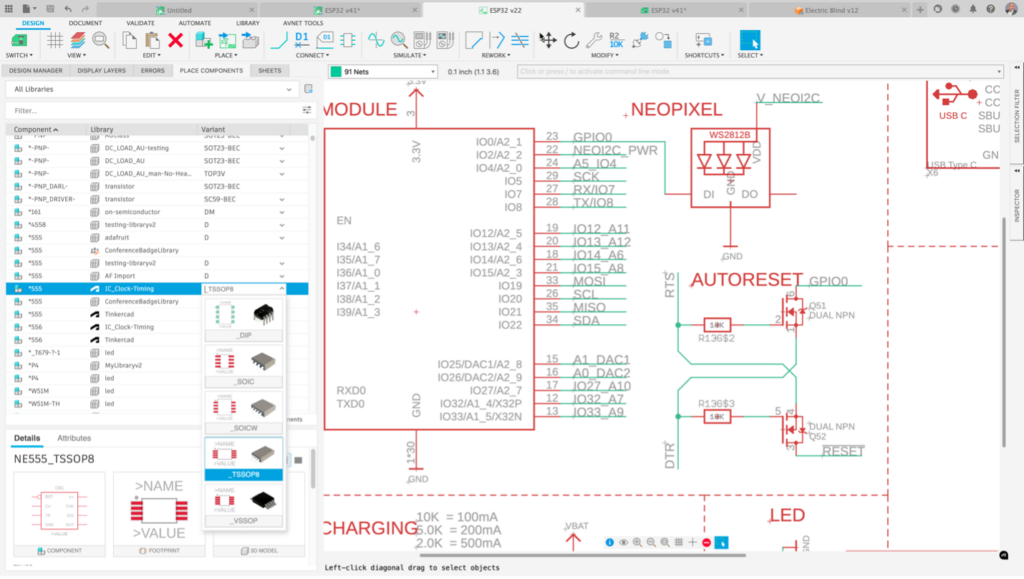

Enhanced Place Panel Column Layout Persistence

Adding components to your schematic is often the first step in designing an electronic product. This is a crucial part of the overall process; simplifying it can significantly accelerate your design workflow. The Place Panel makes it easy to find components by offering a range of filter options, allowing you to narrow your search quickly. We recognized that previously, resizing the Place Part Panel wouldn’t persist after restarting your project. With this update, you can now be confident that any adjustments made to the column sizes in the Place Panel will remain saved across sessions. Additionally, you can modify or reset column settings by right-clicking the column headers, offering you more control and flexibility in organizing your workspace.

Generative Design and Simulation

Generative Design (Simulation Extension)

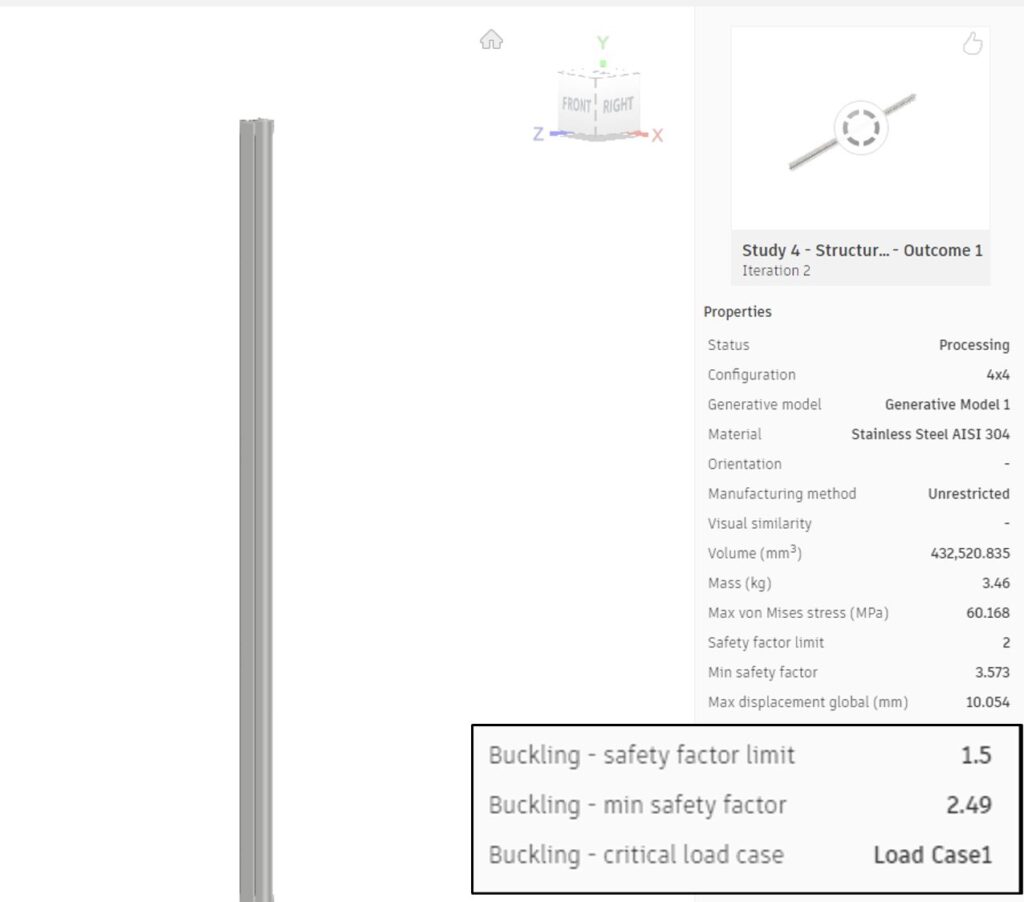

New Buckling Limit Enhancements

Until now, each Objective & Limit option within a study could support multiple load cases, with the lone exception of the Buckling Limit. As of the September update the Buckling Limit has become significantly more versatile, gaining the capability to accommodate multiple load cases. This enhancement offers you greater freedom to incorporate Buckling criteria into your designs, regardless of the number of load cases involved. As part of this enhancement, Generative Design will identify the most critical Load Case for the set Buckling Limit, depending on the given outcome. This useful information will be readily available in the Explore section.

Learn more about Objectives and Limit.

Copy Study Now Available in Configured Designs for Generative Design

You can now copy a Generative Design Study from one configuration to another. Copying a study will contain everything you have setup in the study you wish to copy, including boundary conditions, materials, contacts, study settings etc. This feature will prevent you from having to perform repetitive tasks of setting up the same study across multiple configurations. Some key aspects of Copy Study include:

- Ability to Copy one or more Generative Design Studies from one Configuration on to one or more Configurations.

- User can choose to apply the copied study/studies to a new Generative Model or an existing Generative Model of another Configuration.

- When a study is copied from one configuration to another, it will also include all of the actions user has taken in the Edit Model workspace for the respective Generative Model from which the study is being copied. Therefore, items like Obstacles, Starting shapes etc. created in Edit Model workspace will also get copied over to the destination Configuration.

- If any attribute from the study setup cannot be applied to the destination configuration, then that attribute will be shown as sick and will need user’s action to repair it before they could run the job on the copied study.

Learn more about Copy Study.

Introducing Angular Global Load: A New Feature in Generative Design

We are excited to introduce a new enhancement to Generative Design, called the Angular Global Load. This subtle yet powerful feature allows the application of global angular acceleration or velocity across the entire study setup, effectively representing forces that act on a mass undergoing angular acceleration or velocity.

Learn more about Angular Global Load.

Introducing Linear Global Load: A New Feature in Generative Design

Linear Global Load is here! This impactful new feature allows for the application of global linear acceleration across the entire study setup, effectively representing forces that act on a mass undergoing linear acceleration.

Learn more about Linear Global Load.

Simulation (Simulation Extension)

New Shape Optimization Criteria “Auto” option for Target Mass

Shape Optimization > Shape Optimization Criteria > Target Mass

We added a new option in the Shape Optimization Criteria for Target Mass called ‘Auto’. You can use this option when you’re not sure about the amount of weight reduction you would like to achieve and let the solver automatically determine that value. This option will be selected by default and you can change it to 60% from the drop down and can edit that value as per your requirement.

Learn more about Target Mass.

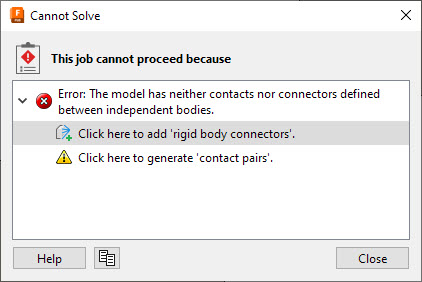

Pre-check will Block an Event Simulation Study with Multiple Bodies without a Contact/Interface Definition

Event Simulation > Pre-check

When setting up a Dynamic or Quasi-static Event Simulation Study which has multiple bodies/components, you now must define a contact or a connector between those bodies/components. Otherwise, the Pre-check will show an error and will prevent you from proceeding with the job submission. This change has been made to reduce the job failures in Event Simulation studies where contacts or connectors are not defined.

New Copy Study in Configured Designs for Simulation

You can now copy a Simulation Study from one configuration to another. The new study will contain everything you set up in the original study, including boundary conditions, materials, contacts, study settings etc. This feature will prevent you from having to perform repetitive tasks of setting up the same study across multiple configurations.

Some key aspects of Copy Study include:

- Ability to copy one or more Simulation studies from one configuration to one or more other configurations.

- You can choose to apply the copied study/studies to a new Simulation Model or an existing Simulation Model of another configuration.

- When a study is copied from one configuration to another, it will also include all actions you have taken in the Simplify workspace for the respective Simulation Model from which the study is being copied.

- If any attribute from the study setup cannot be applied to the destination configuration, then that attribute will be shown as sick and will need action to repair it before you can run the job on the copied study.

Learn more about Copy Study.

Manufacturing

Subtractive Manufacturing

New Machine Avoid Tools for Toolpaths

You now have more granular control over the Avoid/Touch controls with the new Avoid Machines feature. Previously, you could have touch or avoid, but never Touch and Avoid. Now you can add radial and axial clearances or stock-to-leave for surface groups that have one of the following labels:

- Machine: Surfaces to be machined

- Avoid: The tool avoids these surfaces while it machines nearby surfaces. The tool stays clear from the avoid surfaces by specified clearances.

- Gouge: The tool does not actively avoid or machine these surfaces. However, if these surfaces are on the path of the tool then it may gouge and cut through them.

- Fixture: The tool avoids these surfaces by the specified clearances.

Radial and axial “stock-to-leave” values on machine surfaces will be added to the existing “stock-to-leave” value set on the Passes tab.

Radial and axial clearance values on fixture surfaces will be added to those defined in the Setup.

These surface groups live in a new table at the bottom of the Geometry tab in the Avoid/Machine Surfaces section. Surfaces can be selected via existing workflows on the geometry tab and groups will appear in the table. Surfaces can also be selected via the table.

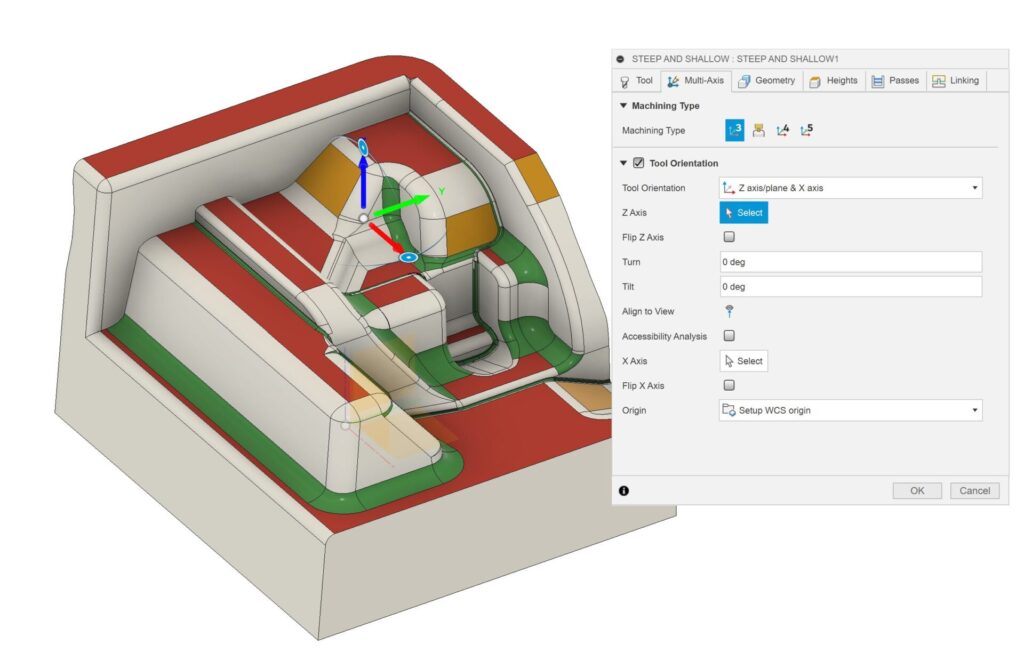

Improved Left to Right Workflow in Toolpath Dialogue (Manufacturing Extension)

We are enhancing the user experience by re-establishing a left-to-right workflow in the toolpath operation dialog, which will be especially beneficial for multi-axis toolpaths. The specific changes are:

- The “Multi-axis” tab will be moved to the second position in the workflow

- The “Machining Type” will allow users to specify upfront whether they are machining in 3-axis, Wrap, 4-axis or 5-axis

- The “Tool Orientation” will be relocated to the “Multi-axis” tab

These changes will prevent cases where you have to go to a later tab, set parameters and then return to an earlier tab to make further adjustments

Learn more about Machining Type.

Undercuts in 3D Contour with 5-Axis Collision Avoidance (Manufacturing Extension)

3D Contour now produces undercutting toolpaths when used with spherical tools and 5-axis collision avoidance is enabled. To enable this feature simply check the “Collision Avoidance” setting in the multi-axis tab.

Note: Undercuts can only be machined with spherical tools whenever 5th axis collision avoidance is enabled.

Improved Selection in Swarf (Manufacturing Extension)

In the Swarf strategy, it is now possible to select both the swarf surfaces as well as the swarf contours when using the “Surfaces” drive mode and the “Contour Pairs” selection mode.

Reduced Unnecessary Cuts in 3D Adaptive Clearing Rest Machining

When using 3D Adaptive Clearing with Rest Machining, it would often include cutting passes that remove little to no actual stock. The parameter “Ignore Stock Less Than” is intended to control how much the cutting passes needs to engage to be included in the final result.

The support for this parameter in 3D Adaptive Clearing has been improved with a new algorithm, that both removes the unnecessary cutting passes, and reduces the amount of fractured cutting passes when the thickness of the stock left is close to the “Ignore Stock Less Than” value.

New Import CAM Data from Linked Designs

Fusion has well-established functionality that allows you to insert an external design into the current design, this workflow lets you create an assembly from existing designs.

Previously any CAM data (Manufacturing setups or operations) in the linked design was not imported. This meant that any toolpaths in the linked design were lost on import. It was not possible to create an assembly of CAM programs, for example to position a pre-programmed CAM part in a vise, or to combine pre-programmed parts together on a multi-part fixture.

The functionality has been improved to allow you to reuse CAM setups and operations from linked designs. The imported CAM data is read-only but you can edit the Workpiece Coordinate System and Tool Orientation to refine how the toolpaths are applied to the new assembly. You can suppress setups or operations which are not required for the new assembly.

The ‘Insert into Current Design’ command imports the external design into the Design workspace exactly as before. When you switch to the Manufacture Workspace you will see a new option to ‘Import CAM Data’

Learn more about how to Insert Cam Data into Current Design.

Spun Profile Improved Calculation

We have made a significant improvement to our Spun Profile calculation engine, innovating on how it processes triangles to calculate the profile. This change will boost performance and accuracy of the profiles calculated, as well as increasing stability of the tool.

New Multiple Passes in the Trace Strategy

As of the September update you now have the option of multiple passes in the Trace strategy. It’s available on the Passes when the Sideways Compensation is set to Left or Right.

Thread Mill Inner Diameter Improvement

Previously, when creating a Thread Mill, Fusion was setting an arbitrary inner diameter that caused inaccurate and impossible to correct rendering issues.

With these changes, the inner diameter now automatically calculates based on the thread profile angle, thread pitch, and diameter parameters. It’s possible to create a very small inner diameter that would not exist, but, most importantly, it should also be possible to accurately create your thread mills.

We also changed the behavior of the Thread Profile Angle parameter. Previously, this was describing something other than the inclusive angle of the thread profile, which would result in more obtuse thread shapes when a smaller angle was entered. It is now describing the inclusive angle of the thread, which should be more intuitive.

If you run into issues creating standard thread mills that you expect to work with the available parameters, please let us know. We know this change does not deliver a perfect or comprehensive thread mill solution, but we hope the bug fix is useful.

Tool Library

Tool Library Improved Empty State Indicators

We’ve received feedback in recent months that sometimes the tool library table view can appear to be empty unexpectedly, and we can do a better job indicating why tools aren’t showing up where you think they should be.

In particular, we didn’t indicate when filters may be filtering out all the tools in a given library. The new empty state page will let you know when this is the case and includes a handy button to clear all the filters so you can see your tool list in full.

We also cleaned up the other empty state experiences, using a common graphic (a tool box instead of a file cabinet, because, you know, tools) and some descriptive text.

Learn more about the Tool Library.

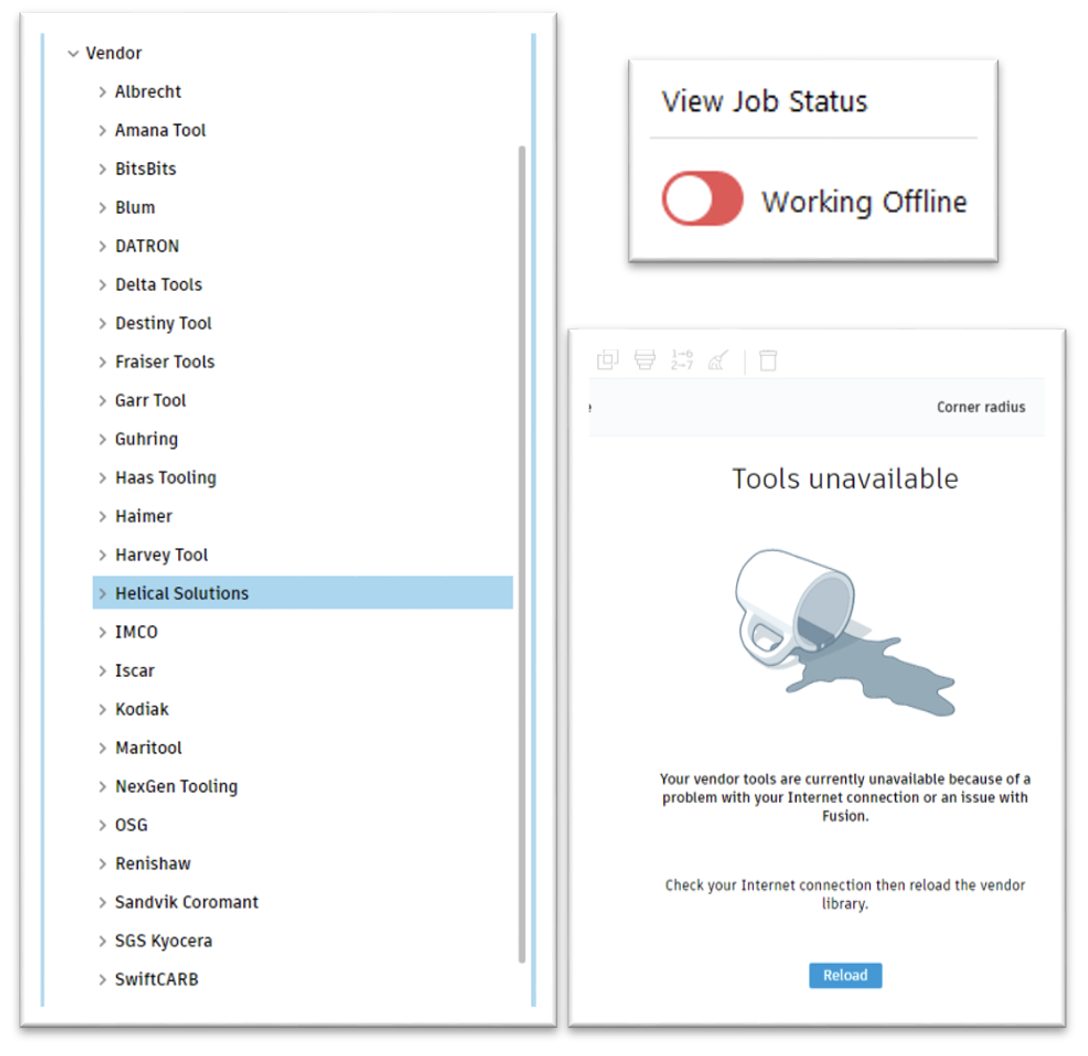

New Vendor Tool Libraries

We are bringing vendor tool libraries right into the tool library interface! Previously, to get access to the vendor libraries we build in partnership with tooling OEMs, you would have to visit the hosting website, download, upload into the tool library, and then deal with constant loading of that data when using the tool library day to day.

Now, the vendor libraries are available right in the library tree, with the vendor library streaming from an online repository. This way, there’s no extra steps to get access to a new vendor library. This also means there shouldn’t be any performance implications, as we only load the vendor tooling data while you are actively interacting with it. To take a tool or holder and use it, you can select for use right from the vendor library or drag and drop (or copy and paste!) into an existing cloud, local, or document library to use and reuse the tool. Tools are read-only while you are viewing them in the vendor library, but once you move the tool or holder to a cloud, local, or document library, it is editable so you can make any needed adjustments.

Note: Since the tooling data is stored and accessed from an online repository, it is not accessible while your computer or Fusion are in an offline state.

Learn more about Tool Libraries.

Nesting

New Automated Arrange

We’re excited to announce the addition of ‘Automated Arrange,’ which brings significant improvements to the Arrange feature, including:

- An option to prevent part-in-part arrangements

- An option to ‘Create Copies’ or ‘Move’ original components

- Creation of Arrangement nodes in the browser tree, with selection cross highlighting across objects in the browser, canvas, and the timeline.

- An option to create multiple manufacturing setups directly from arrangements

- Enhanced associativity between model, arrangements, setups, and toolpaths.

For Manufacturing Extension users, there are a few additional enhancements to the Arrange workflow:

- Part quantity control with a global value, multi-edit, and individual overrides

- Filler Parts setting to maximize material utilization

These improvements are designed to streamline your Arrange to Manufacturing workflow and enhance productivity.

Before this feature went live, it was implemented as an Insider Preview, if you want to see more fantastic features like this before they go live to the general public, head over to the Insider Program for an early look at the latest and greatest.

Learn more about Automated Arrange.

Improved Silhouette Detection for Arrange and Nesting to Prevent Part Overlaps

Previously, Arrange and Nesting would sometimes produce results with either missing parts or overlapping parts. This would typically occur when one or more contours of the offending part wasn’t detected as fully closed. While there was a workaround available to mitigate such scenarios, it was very tedious and not readily discoverable.

The improved silhouette-based algorithm now uses robust approximation to automatically fill any tiny gaps, ensuring closed contours and thus prevents part overlapping in nest results.

Additive Manufacturing

Fill build Volume Improvements

The Fill Build Volume tool lets you fill the unused space in an additive machine’s build volume with multiple copies of a part. Filling the build volume can be useful when printing batches of identical parts or including additional parts around a main part. This can help maximize production capacity.

With the September 2024 release, the fill build volume command now includes a new filling type called “3D (true shape)”. If you use this new filling type, Fusion will consider the true shape of all components instead of their bounding boxes. This will generally result in Fusion adding more parts to the empty volume of an SLS or MJF 3D printer.

This new filling type also allows you to consider different part orientations by rotating the part around its X , Y or Z axis during the nesting process so that Fusion can try arranging parts in various orientations to make use of the full build volume of a given 3D Printer.

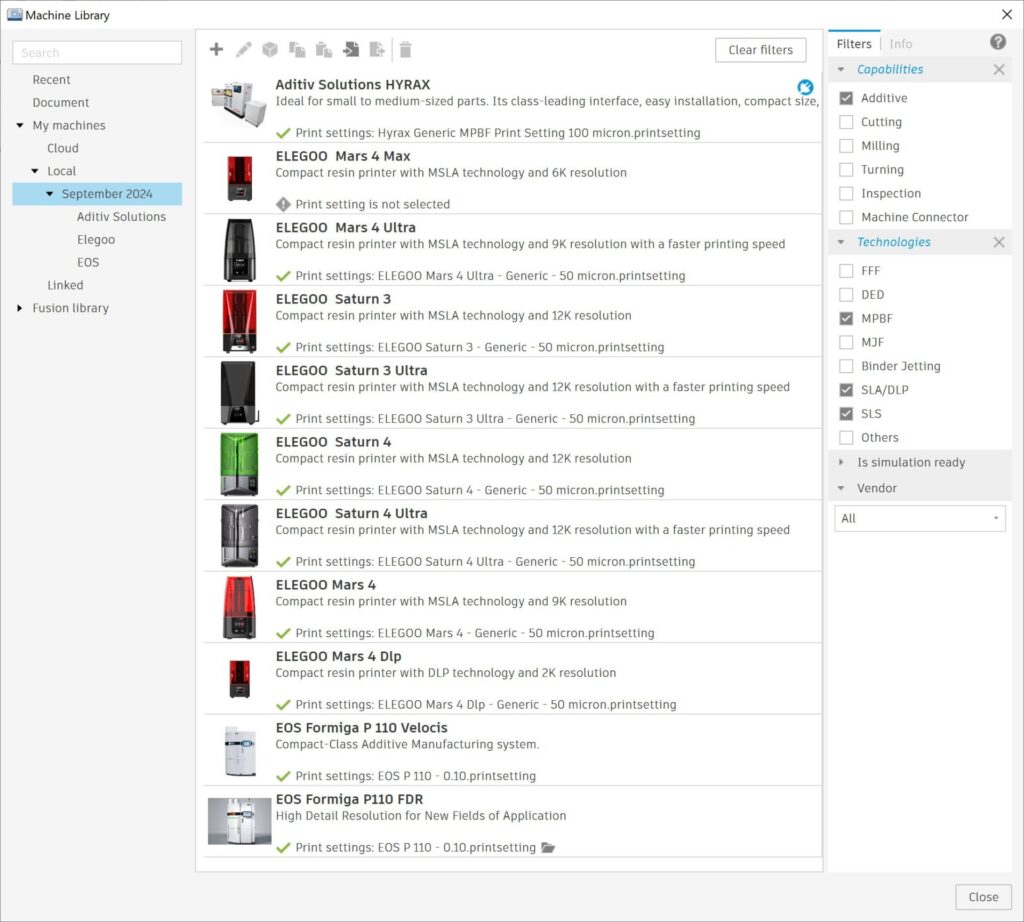

New Additive Machines and Print Settings

With the September release we are excited to include 8 resin 3D printers from ELEGOO in our machine library along with their corresponding print settings. After creating an additive setup, orienting and arranging your parts within the build volume of your ELEGOO printer and generating the necessary support structures you’ll be able to slice your models and create the machine file ( *.goo file) and 3D print your parts.

This release also includes an update to the EOS P110 machines. EOS P110 FDR and EOS P110 Velocis printers now contain the relevant No-build zone as defined by EOS. When creating an additive setup with these machines in Fusion, the additive arrange command as well as the fill build volume commands will avoid placing components within the No-build zones.

This release also adds a new metal powder bed fusion machine (HYRAX by Aditiv Solutions) and it’s associated print setting to Fusion’s machine library. Please note that creating an additive setup with a metal powder bed fusion machine requires access to the manufacturing extension.

Updated Support Structure Dialog

With this release we reorganized the options within all relevant support structure dialogues so that they are presented consistently regardless of whether you are using bar supports, volume supports or polyline supports. For example, all the settings that control how supports are connected to parts as well as the build plate are now located within the Connections tab for relevant support dialogues. For additional information about where each option is located, please refer to the online help documentation.

Enhanced Post Processor and Machine Simulation

Looking for the latest post processors and machines updates? This September we released a ton of new updates and improvements to many of the open-source Post Processors and Machines we offer for free. Within this release you will find improvements to post processors including Generic Post Processors, Milling Post Processors, and Turning Post Processors. We also added new machines to our Machine Library, updated our Workholding library, and improved functionality around the Autodesk CAM Post Processor engine.

Learn what’s new for Post Processors and Machine Simulation this September.

Missed the August update? Learn what’s new for Post Processors and Machine Simulation from this past August.

APIs

Update of Python Version Fusion has updated its Python version to 3.12.4 in this release.

This change should not impact most Python and Fusion API users. Those impacted are developers who deliver their apps using .pyc files and their users. If you see a message like the one shown below when you start Fusion, you should check the app store or the developer’s website for a new version compatible with this update. You should contact the developer directly if you need help finding an update.

If you’re wondering why Fusion is updating the Python version, Fusion uses Python internally for some tasks, and there was a bug in the current version of Python that could cause Fusion to crash. This update fixes that problem.

Upgraded Cloud Data API

The upgraded Cloud Data API enhances capabilities for developers and users, providing seamless integration with cloud-based data adding access to configuration data from Fusion designs. This upgrade empowers users to interact with and manipulate their design data programmatically, fostering greater flexibility and customization in their workflows.

All other API Enhancements

For a detailed list of all the API enhancements and fixes for this release, see the API What’s New page in the help.

Customer Reported Fixes

Forum Reported Fixes

Your feedback matters to us, and we’re dedicated to improving your experience with every update. You’ve shared your thoughts, and we’ve listened and acted. Within each workspace our teams are constantly working to make your experience within Fusion as smooth as possible. If you haven’t already, now is a great chance to check out what forum reported issues we have addressed in the September update.

Learn more about the Design Forum Reported Fixes.

Learn more about the Electronics Forum Reported Fixes.

Learn more about the Manufacturing Forum Reported Fixes.

Additional Fixes

Local File System Document Icons for Fusion-Compatible File Formats

In addition to the existing F3D icon visible when exporting a Fusion document, we have also added icons for additional formats supported by Fusion. These icons are visible in Windows Explorer and macOS Finder when Fusion is set as the default file handler for a given file extension.

“Selection Filters” Tooltip is Now Less Likely to Cover Flyout Menus

The tooltip for Selection Filters has a habit of covering the filter flyout menu, making it impossible to select several filter items in the list.

The tooltip will now attempt to move to a less-obstructive location, and disappear when hovering the flyout menu.

Message Box Dialogs No Longer Compresses to an Unreadable Size After Resuming From Device Sleep

Message boxes (e.g. Offline Mode) will now maintain the correct size when the device sleeps and wakes.

Fixed “Unsaved changes” Dialog Behavior

In a past release, Fusion’s message boxes had window controls (the X to close in the top-right) added to them globally at a template level. For the Unsaved changes dialog, this had the unintended side effect of closing the window with the X to behave the same as clicking “Don’t Save.” The window controls for this dialog will now behave the same as clicking Cancel (just like the Escape key does already).

Application Update Progress now Shown in the Windows taskbar

We improved Fusion’s integration with the Win32 Shell. Now, the taskbar shows application update progress, making it easier for you to know when Fusion is ready to restart while running in the background.

Fusion No Longer Moves Behind other Applications When the Progress Bar Hides

Some workflows (e.g. toolpaths) that triggered a progress bar were inadvertently causing the entire Fusion application window to hide once the command completed, instead of just hiding the progress bar itself. Fusion should no longer jump behind other applications as a result of the progress bar hiding when these workflows complete.

[Windows] High DPI Scaling Option Restored

The option to disable High DPI scaling in Windows was broken after a recent update. It is now functional again for those who need this option for compatibility purposes.

Join the Insider Program

Do you want to engage more with the Autodesk community, use Insider previews, and test out the latest build one month before it’s released to the general public? Check out the Fusion Insider program! The Autodesk Fusion Insider Program enables you to access the next version of Fusion and all the new features, improvements, and fixes, 3-4 weeks before the general public. As a member, you’ll gain inside knowledge of when we are deploying an update, what’s new, and what’s coming next . You will also have the opportunity to join exclusive events, try pre-release functionality, and give feedback straight to the product teams.