& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

18 min read

V.2.0.6503

FIXED: There was an issue with the Pattern feature in Manufacture workspace where Component Pattern went missing from the list of pattern options. Now it’s back.

V. 2.0.6440

[toc]

New! Session Management

Many of us use Fusion 360 on multiple machines, since work doesn’t just end when we leave the office or the machine shop. Previously if you logged into Fusion 360 on multiple machines with the same account, both machines would have active sessions running and there wasn’t an easy way for you to manage your sessions, or decide what to do with the remote session. Now there is.

In the update, we’ve introduced a better session management experience. If you sign in to a 2nd session of Fusion 360 on a different machine while you were still logged in on a previous machine, you’ll be prompted with a dialog (on the newly signed in session) that shows other sessions that have been previously left logged in, when they were open, and when was the last activity. You’ll be able pick 4 options:

Once you press “Continue”, you’ll get a confirmation message asking you to confirm that this is what you want to do. Clicking “Continue” again will trigger that remote session to react to your selection.

Suspend the remote session and continue working in the one you’re on

Suspending the remote session will allow background tasks like rendering, sim solves, or CAM tool-path calculations to continue without the interruption of closing the session down.

Shut down the remote session and continue working on the one you’re on

Unlike the suspend option, shutting down the remote session will not only close the remote session, it will also remotely sign out of the account that it was logged into before the Fusion 360 closes.

The last 2 options applies to the session you are logging into – you can either sign out of your existing account and log in with a different one, or simply just close Fusion 360. To learn more, check our our knowledge article.

Improved! Fusion 360 now appears in Spotlight Search on macOS

Many of you have told us about this, and have posted in the forums as well as the IdeaStation. We’re happy to report that it now works as it should! Now when you want to launch Fusion 360 from Spotlight Search on macOS, you can start typing Fusion 360 and see it show up. Indexing will impact how it shows up, because it may not have indexed it yet, but eventually it will show up correctly.

Fixed: QAT Toolbar goes blank issue

Some of you on Lenovo machines told us that parts of the toolbar became blank when you logged in, making it really hard to access the file menu, save icon, and document tabs. You pretty much had to rely on your memory of where they are or restart Fusion 360 and see the bar was back. Now we made sure that the bar won’t disappear again.

Fixed: Pattern and Mirror are back in Sheet Metal Create panel

Apparently the Pattern and Mirror commands were missing from the Design workspace > Sheet Metal tab > Create panel drop-down menu. We found them hiding in the old toolbar, so we brought them into the new one.

Fixed: Mesh Palette not showing up

Ah yes, the Mesh palette. When you get into the Mesh environment, the mesh palette should have appeared automatically, allowing you to control the size of your selection brush. For some weird reason it also went missing, but we’re glad we found it and now it shows up as it should.

Fixed: File Export with Xrefs exporting as Inventor assembly will now export as zipped

When you export a design with Xrefs as an Inventor assembly, it should export as a zipped file with your IAM and your IPTs neatly zipped up in a single file. This wasn’t happening, and apparently all you got was an IPT. Now it’ll export as a ZIP file.

Fixed: Issue with Fusion 360 detecting the wrong graphics card

Andy.c made us aware of an issue he accounted where even after he had updated his graphics drivers, Fusion 360 was still insisting that he was using the old drivers, and wasn’t looking at the updated ones. We went ahead and updated our graphics engine, and now Fusion 360 will detect the latest drivers like it should.

Fixed: Anti-aliasing issue on sketch lines

Remember how you sometimes your sketch or model edges look jagged even though you had anti-aliasing turned on? We remember. This was an issue we logged a long time ago, and because we updated our graphics engine, this issue went away. Now your edges will look nice and smooth.

Fixed: Cloud rendering and local rendering discrepancies

Some of you have reported that the cloud rendering results looked slightly different than the

local rendering results. They should look identical, since they are using the same rendering engine, but apparently something was wonky.

New! Convert to Sheet Metal

“Convert to Sheet Metal” is a new command in Sheet Metal tab which will attach sheet-metal-ness to any existing part, which opens doors for all the rest of the Sheet Metal commands to be used on that part. This will allow you to import your existing sheet metal parts into Fusion 360 and further work on them, or a Fusion 360 part which was modeled without using sheet metal commands can be converted to take sheet metal benefits.

We made this a history-based parametric feature, which means that after converting a body, you can go back and modify your model in any way and see those changes get reflected on the converted sheet metal part. You can use this method to create cool stuff with connected sheet metal rules, we can’t wait to see what you do with it.

How it works

In order to convert a body into sheet metal, the part needs a sheet metal rule to govern its geometry, and the most basic parameter is the thickness. Since we have the body already, the thickness has to match to that body. To save you from manually inputting the thickness, we’ve built in some clever thickness detection functionality where you just need to click on a face (this also doubles as source body input) and Fusion 360 detects the thickness at the point of click. Hence where you click on the body matters, so make sure you click on the wide, flat area of the part. The thickness value will lock down in the rule here since the value is driven by the part’s geometry and not the other way around.

Even better with AnyCAD

And yeah, if you’re taking advantage of our AnyCAD workflows, this will also work with your other CAD formats. Updating part thickness on a SLDPRT will trigger an update in Fusion 360, updating the rule thickness, which will also update the Sheet Metal features created on top of it with new thickness, updating its Flat Pattern, and updating the 2D drawing.

Improved! Assembly handling performance

Sometimes when you’re working with assemblies that contain thousands of parts, moving components or editing a joint on a component can bog Fusion 360 down, which leads to summoning the wretched black bars to appear.

Left: moving a PCB assembly took a lot of time | Right: Invoking Joint or editing existing joints took time to load

There have also been cases where components were getting misplaced and joints that were previously placed were not obeying their rules after you performed a “Get All Latest” to update your X-refs or a Compute All.

After diving deep into the code base, we’re glad to report that we’ve dramatically improved the performance of how you handle larger assemblies by approximately 77.2% to 99.3% for components moves and 33.3% to 99.11% for joint edits. Woot!

Fixed issue with 3 Points Plane and mesh bodies

lparedesJ6QNG told us that he was having trouble with putting a 3 point plane on a mesh body, and that Fusion 360 was giving him an error every time he tries to do it. We looked into this behavior and found some creepy crawlers crawling around the code, infesting it with nonsense. We called the exterminators and they quarantined the area off – now it’s free of bugs and you can place a 3 point plane on a mesh body again.

Fixed issues with Pin Slot Joint not working

Awhile back, TrippyLighting told us on the forum that Pin Slot joint wasn’t working when you wanted to use it. Sorry about the delay on this fix, but we fixed it. Pin Slot joint now works as it should.

Fixed issue with revert capture position of components

There have been a slew of challenge joint-related bugs that we’ve been squashing, and this was one of them. Previously there was an issue where if you moved a component joined to another component and captured it’s new position, reverting its captured position didn’t actually put the component back to its original location. Now it does.

Fixed issue with driving Revolute joint limits

Swebal reported a joints issue where the Revolute joint would get stuck when he was driving the joint limits and watching the joint animate. We found that parts of Fusion 360 got rusty, so we hit it with grease and now the Revolute joint won’t get stuck again.

Fixed issue with not being able to delete a body

David.antliff told us about an issue where he wasn’t able to delete or remove a body. Every time he tried to remove it, Fusion 360 gave him a “Compute Failed” error. We found the parents to those “orphaned” bodies and now this issue is fixed.

Fixed issue where Boundary Patch did not work properly

Dprusock encountered a weird behavior where applying a patch surface on a model he was working previewed fine, but when he clicked OK, the command failed to compute. This shouldn’t have happened, but luckily, Jeff Strater showed him a workaround and we were able to get the issue fixed in this update.

New! Advanced Physics Preview

The types of problems you are wanting to solve with Generative Design are becoming more and more complex. To help you solve more of these challenges, we are introducing new preview functionality for advanced physics. In this update, you will be able to opt-in to using an Advanced Physics Solver for generative studies.

This solver will allow for the inclusion of modal and displacement limits with your objectives. Currently, only unrestricted and additive manufacturing processes are supported with these new limits and by requesting modal or displacement limits to be enforced the commercial solver will not create outcomes. You will see additional outcomes when modal or displacement limits are not specified for unrestricted and additive manufacturing processes. Since this is still a preview, we’d love to hear your feedback so we can make it even better. For more information, see Advanced Physics.

New! Outcome and iteration labels in Explore

We know that using Explore and finding the right outcome is a major part of using Generative Design. You’ve been asking us for a way to “favorite” specific outcomes to make them easier to compare and be identified amongst one another. Now you have the ability to apply labels to outcomes or specific iterations of an outcome. These labels will be added as a filter to the browser and can be used just like any other filter in the various Explore views. For more information, see Label an outcome iteration.

New! Materials filter in Explore

In addition to our Labels workflow, we’ve also heard that you wanted to ability to filter by materials. Sounds like a plan, so we went and added it.

New! Ready to Explore samples

We are continuing our focus on making it easy for users to get up and running with the fundamentals of generative design. We have added another set of samples to our Generative Design samples. In the Ready to Explore folder, you will find studies pre-populated with outcomes in Explore. This will allow you to review the types of results you might expect before solving your first generative design.

Improved! Tooltips for 2.5 Axis Milling directions

There now tooltips to the tool directions for 2.5 axis milling to help you understand the how outcomes will be generated using this manufacturing method, as it generates outcomes for a given direction differently than our other methods.

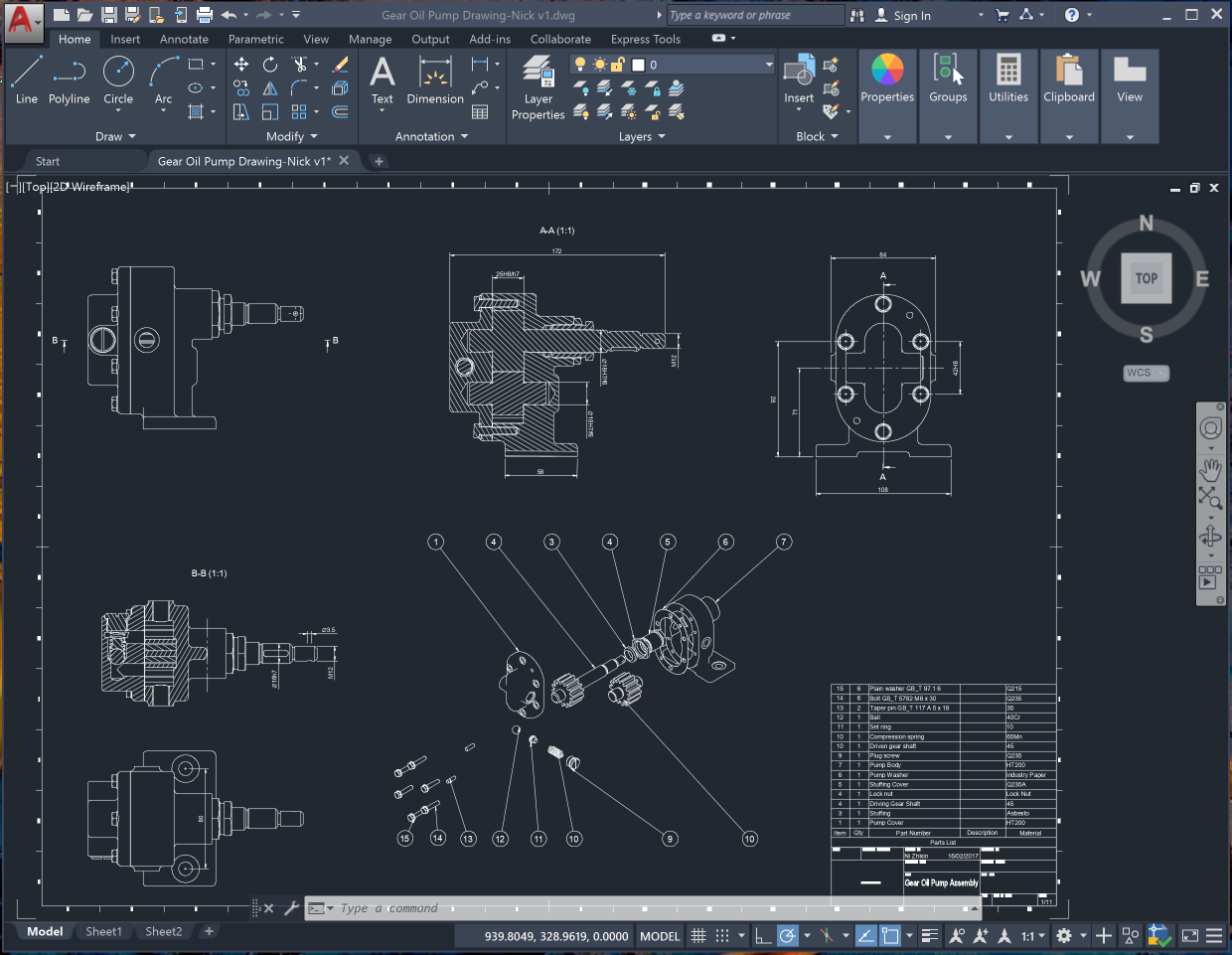

New! Export sheet as Simplified DWG and DXF for 2D Drawings

Good news everyone! You’re able to output a 2D Drawing sheet as Simplified DWG or DXF, which will work nicely with other downstream software that you’re using alongside Fusion 360.

Previously, if you opened an AutoCAD DWG in another CAD application, the model views would sometimes come in as just red boxes. With Simplified DWG, the model views come in as line entities that are editable in other CAD software and not just AutoCAD.

Simply right-click on the active sheet in the 2D Drawings workspace, and you’ll see the option to output there.

When you select the DWG option, you’ll be able to choose between Simplified DWG or AutoCAD DWG. Simplified DWG is a single sheet; AutoCAD DWG is a full multi-sheet drawing and is the same format as we had previously. After you click OK, you’ll be prompted for the name and location of where you want to save it to.

There are still lots of 2D Drawings projects in the pipeline, and rest assured, we’re on it.

Fixed issue with the Back placeholder view being previewed Front

We fixed an issue where if you added a Back view when creating a drawing template, it resulted in a Front view instead when you created a drawing using that saved template. Some wires must have been crossed. Sorry about that!

New! Tabbed Toolbar now in Manufacture Workspace

Now when you toggle over to the Manufacture workspace, you’ll notice that the toolbar now also has tabs, housing the appropriate tools for Milling, Turning, Additive, Probing, and Fabrication operations. Each tab is pretty self explanatory, but here is a quick run-down.

You’ll find all your usual 2D, 3D, Drilling, and Multi-axis tools under the Milling tab.

The Turning tab includes all of your turning strategies.

Additive will house all your advanced additive manufacturing tools, as well as supports.

Probing includes your probing tools such as Probe WCS, Probe Geometry and Inspect Surface (which are available through Extensions only).

The Fabrication tab includes laser-cutting.

New! Profile Roughing and Finishing Turning improvements

We’ve added some major improvements to the Turning strategies, such as new Profile Roughing and Profile Finishing strategies. In addition to the new Profile Roughing and Finishing strategies Tangential Extensions and a list of detailed improvements take turning to a new level.

Note: The old profile turning strategies are no longer visible but they can still be edited, posted and copied between files or saved and reused as templates if your not willing to let them go yet.

Previously, both profile roughing and finishing were bundled in the same “Turning Profile” strategy but now they have been split into two separate strategies. The reasons for doing this were to:

With these new strategies, you’ll also find some really nice improvements sprinkled throughout the 5 tabs. Options like Tangential Extensions, Tool Limits, Canned Cycle in Roughing, cleaned up Compensation types, really enhance the strategies, enabling you to dial in all the important details to make perfect parts. There’s a lot to talk about, and in the spirit of being concise, you can head over to our blog post that we posted a couple days ago to dive deeper into these features if you’d like to learn more.

[icon name=”arrow-right” class=”” unprefixed_class=””] What’s New in Turning Profile Rough and Finishing

Improved! [Extension] Tool Axis Limits for Steep and Shallow

We have added the ability for you to set tool axis limits for the steep and shallow toolpath. You’ll be able to set the Tilt Limit (angle ) and Mode: remove toolpath or move tool axis.

Improved! [Extension]: Probe Geometry – Minimum update threshold default value

We’ve changed the minimum update threshold value for Probe Geometry to zero, so that the tool wear value always updates on default unless the user changes this threshold value.

Improved! [Extension]: Load Surface Inspection results from Fusion Team

It’s now possible to import Surface Inspection results from Fusion team.

Improved! Ramp Angle in 2D Bore

We’ve added the option to set the step down for 2D Bore based on angle in addition to pitch per Steinwerks’ IdeaStation suggestion. We know many of you have been asking for this for awhile, so we’re excited to roll it out!

Improved! Import Surface Inspection Results

“Import Inspection Results” (in the ‘Actions’ Menu, for evaluating “Inspect Surface”) now lets you import results from Fusion Team in addition to the local PC, making the transport of measurement results easier.

Additionally, “Import Inspection Results” now creates a results folder accessible from the browser tree with the name “Measure<n>”, where n is the name of the imported file of points. This makes it easier to relate measurement results to a particular time & date or instance. If you are producing one or more batches of components there may be multiple inspection results from different times, so this will help you identify them.

Lastly, this option is now available even to customers who don’t yet have the Manufacturing Extension, or who had it at one time then didn’t repurchase — you’ll be able to check out sample files in order to experiment with the Surface Inspection workflow or import and evaluate results from “Inspect Surface” routines created when you did have the Manufacturing Extension.

Improved! Post Filtering

The posts in the post library can now be filtered based on their capabilities – this will allow you to more quickly find a post suitable for performing the required task

Improved! Draw turning compensation point in toolpath simulation

We’ve added the option to display turning tool compensation points during toolpath simulation, Simply check the ‘Programmed Point’ checkbox as shown below.

Improved! Export machine configurations

You can now export your machine configurations locally or or share it with your team.

Improved! Accessibility Analysis

We’ve added a new option in the Accessibility Analysis tool which highlights inaccessible points from both positive and negative directions.

Fixed: Tool Modification Causing Selection Loss

We’ve fixed a regression where certain tool modifications were causing a loss of selected geometry chains – thanks to Ariel for calling out this bug.

Fixed: Bi-Directional Hole Ordering Not Consistent in all Models

We fixed an issue where the new bi-directional hole ordering option introduced in the June release wasn’t working as it should in certain applications where hole rows weren’t exactly aligned in Y – we’ve introduced a larger tolerance metric for identifying hole rows that should fix this.

New! Visual Studio Code replaces Spyder as the default editor for your add-ins

Previously you wanted to edit an add-in script, Fusion 360 was really proactive at grabbing Spyder Editor for you, not even checking with you to see if you wanted it or preferred using something else to edit. We’ve toned it down a bit, and instead of defaulting to Spyder, we’re giving you the option to install Visual Studio Code as the preferred code editor. You’ll still have the option to point Fusion 360 to an editor of your preference, but if you don’t have an editor, then you can continue and install Visual Studio Code.

For more information about this, check out our help documentation.

Fixed: Out-of-date icon goes away correctly after Get-all-latest

The fine folks over at Bommer told us about an issue where, when they were working with the API, the “Out-of-date” icon was not obeying the “Get-all-latest” event and wouldn’t go-away. Sorry about that – sometimes these icons get cranky and require more discipline. Now it should behave correctly.

Fixed: Resize Palette even if showCloseButton is False

Rolandas.vegis found a bug in the API where the only way he was able to resize the palette was to set showCloseButton to True. We squashed this bug so now you’ll be able to resize the palette even if showCloseButton is set to False.

That just about wraps up this update. Hope these features help you in your day-to-day use! Stay tuned for the next one!

By clicking subscribe, I agree to receive the Fusion newsletter and acknowledge the Autodesk Privacy Statement.

Success!

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.