There’s no denying that sheet metal plays a pivotal role in projects across numerous industries. Sheet metal is commonly fashioned from steel or aluminum and typically takes a thin and flat form. Despite this, sheet metal alterations are commonplace — and essential — depending on the application in question. This is where the forming of sheet metal parts comes into play.

Sheet metal is widely used due to its formability, ductility, and tensile nature. Manufacturers thus have a central goal: manipulating malleable metals accordingly while preserving structural integrity. Manipulation is achieved in multiple ways and to multiple tolerances. This article will break down some sheet metal forming processes and their relevance within specific industries.

Bending Sheet Metal

As one might expect, bending involves altering sheet metal’s shape through applied pressure. Doing this by hand isn’t typically possible, and thus industrial methods become necessary to reach the desired shapes. Manufacturers employ different types of presses to achieve this, such as high strength roll forming machines. They must also have intimate knowledge of their medium’s physical properties to avoid causing damage or excessive deflection during the machining process.

Press brakes and machine presses are ideal in these situations. Hydraulic, pneumatic, mechanical, or electrical forces may be applied to different locations along with the sheet. These, paired with a forming die, help the metal reach its intended form. The metal on-hand will determine how much force is applied, as well as its direction.

Press brakes are convenient since punch and die combinations are plentiful. These lend themselves to numerous types of jobs.

Applications

Sheet metal bending is indispensable for automotive production. Today’s vehicles aren’t just boxes with four wheels, and panel corners have a certain radius, which helps create visual consistency. In the case of supportive pillars, sheet-metal bending forms a bridge between aesthetics and occupant safety.

In terms of architecture, a key focus of modern building construction is flow. Gentle curves and geometric structures — both internally and externally — are hallmarks of parametric design.

Any application requiring a unique shape will rely on bending processes. Another notable example is the aerospace industry. Manufacturers commonly fashion passenger-and-military aircraft from aluminum alloy and titanium alloy. These metallic compounds are highly flexible and retain their shapes (aka “have memory”). Such attributes are essential for curved structures like fuselages, wings, and engine mounts.

Curling Sheet Metal

Not to be confused with bending, curling focuses on fixing imperfections stemming from a sheet’s production. Sheet metal is cut to various predetermined dimensions during the manufacturing process. While tooling can effectively create precise (straight) edges, there’s a significant drawback: burrs. Just like cutting wood sharply produces rough edges, the same happens to steel and aluminum.

Burrs aren’t just a safety risk — these sharp edges cause tolerance issues that can potentially hamper fitment and product quality later on. Additionally, a type of residue called “slag” forms during specific cutting processes. These splatters of cooled metal must be removed. Special deburring machines do this, while grinders smoothen out any hazardous artifacts.

Applications

Curling has widespread importance across multiple industries. Consider modern architectural design, where panels must meet cleanly and seamlessly. The same goes for automotive applications — particularly bodywork like doors and quarter panels. These aren’t only common touchpoints for owners or passersby. Finished edges elevate one’s overall impression of quality, craftsmanship, and harmony within a given design.

Ironing Sheet Metal

When uniformity is paramount, companies typically resort to ironing. This process involves taking an inconsistently thick piece of sheet metal and creating consistent edge-to-edge thickness. Pressure is required on each side of the sheet, which is applied progressively by two opposing dies; a punch forces the sheet through until completion.

Ironing is also related to deep drawing, which relies on directional pressure to stretch a metal sheet. An attached punch facilitates this by pressing between two binders, holding the sheet in place. Unlike bending, the focus isn’t necessarily on shaping. Deep drawing aims to change the height or thickness of a metal wall.

Applications

Ironing and deep drawing have great importance in the automotive industry. These processes are used to form body panels while ensuring that bent pieces won’t be inconsistent. Also called stamping, deep drawing helps make the following:

- Engine control components

- Cylinders

- Frames and suspension components

- Seals

Both processes are also essential in the beverage industry because drink cans have a required thickness across their walls. They must be adequately robust and sized consistently for packaging and display. The ironing process guarantees that weaknesses stemming from thin spots are eliminated.

However, the options are vast. The list of compatible metals is long because ironing and deep drawing leverage acute pressure. Aluminum, steel (low or high-carbon), brass, and other alloys respond well to these techniques.

Laser Cutting Sheet Metal

Companies now leverage powerful applications like Autodesk’s Fusion 360 in modern manufacturing workflows. The advent of CAD and CAM have unlocked laser cutting — a precise sheet metal forming process that directly influences a sheet’s size and silhouette.

Fabricators favor laser methods for their granular control, speed, and compliance with pre-programmed cutting blueprints. For example, a laser cutter may follow schematic-based instructions to achieve the desired result. CNC machines make this possible.

While not bucking the issue entirely, laser cutters produce less burring than metal-on-metal cutting processes. However, improperly-calibrated lasers (poor focus, alignment, beam power, or speed) can cause burring. Other forming processes may be needed to resolve this.

Applications

Any application that demands precisely-shaped sheet metal will benefit from laser cutting. The fact remains that few metal sheets will immediately fit an application without modification. However, to cite one example, laser cutting is useful in the art industry, where precise cutouts may boost a product’s visual flair. Automakers may also leverage laser cutting to craft a variety of internal and external parts.

Punching Sheet Metal

The punching process is fairly straightforward. A punch and die team up to form holes of specific shapes in sheet metal. The end goal is to craft a sheet with precise punchouts, changing its original form to fit a design. The material removed is recycled or discarded.

The blanking process — a derivative — also relies on punching. However, the material extracted from the original sheet metal is the prize.

Applications

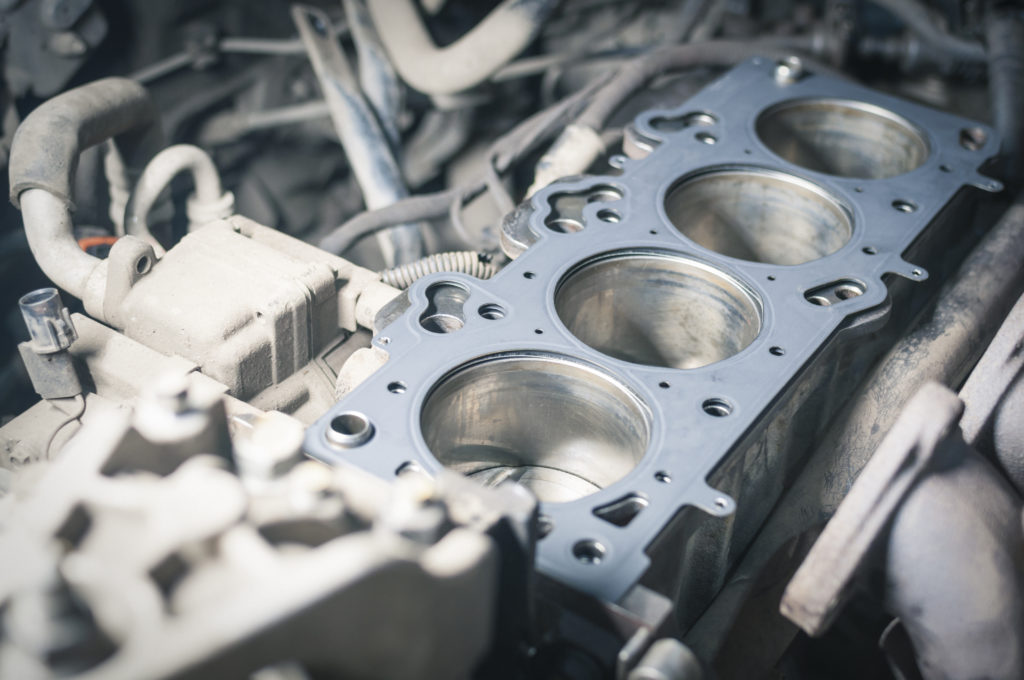

Punching and blanking are used to produce multiple diverse, specifically-shaped components. Vehicles, for example, require numerous gaskets that keep fluids from escaping their proper channels. In particular, head gaskets have precise cutouts for engine oil passageways, cylinders, and the engine block’s overall shape.

Companies may also use these processes to form power-tool components and electronic components. Manufacturers who produce microelectronics at scale can create multiple parts from one piece of sheet metal using these methods.

Autodesk’s Fusion 360 features a sheet metal workspace that lets you create sheet metal bodies and produce manufacturing data for sheet metal parts. Download Fusion 360 to experience a comprehensive sheet metal workflow for your next project.