This post is also available in: Français (French)

As smart devices gain complexity, manufacturers using cloud-based product development solutions like Fusion 360 are ahead of the competition. This article delves into the data to give you advice for adopting a streamlined workflow between stakeholders.

An increasing number of traditional mechanical products are transforming into smart, connected devices that require electronics, electrical distribution systems, and onboard software. This single trend dramatically changes how manufacturers work because smart devices require multiple engineering teams to collaborate, establish new workflows, and solve new problems directly related to the design constraints and data management issues of connected products.

New research commissioned by Lifecycle Insights points toward a product development IT ecosystem that is better equipped to make smart, connected products without compromising schedules or budgets. In this series of blog posts, we’ll look at some key findings from this new research and see what steps manufacturers can take to improve efficiency and performance.

The complexity of smart, connected products is increasing at an unprecedented rate, driven by a combination of digital innovations that make these products possible and rising consumer demand for products with these new capabilities.

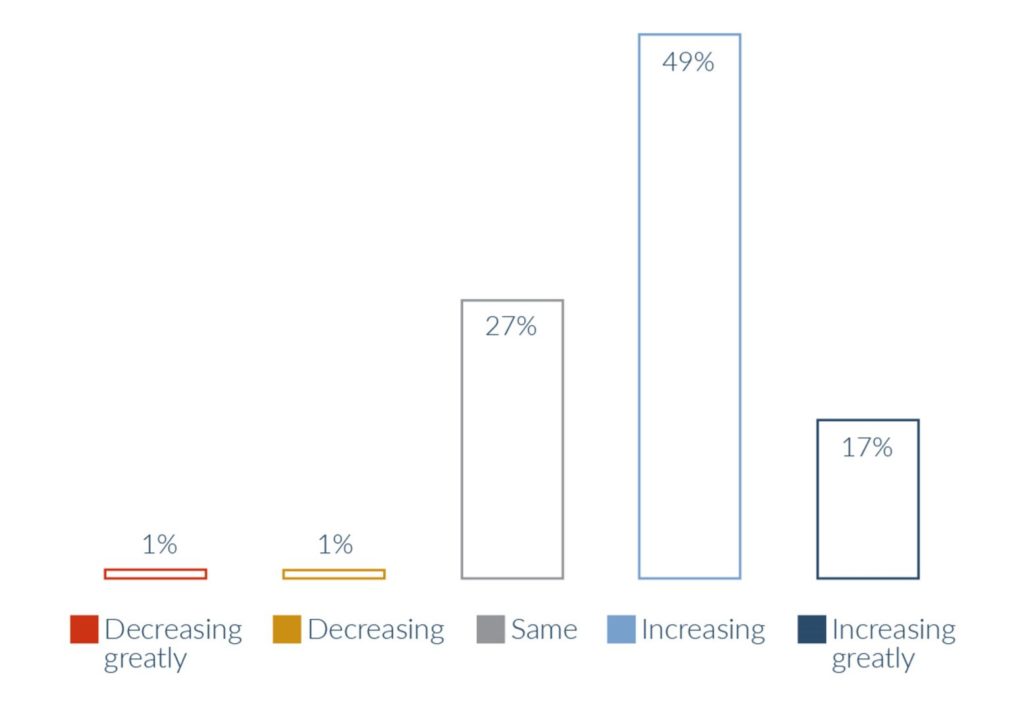

In a recent study, a majority (two-thirds) of electronics engineers said that circuit board complexity is either increasing or increasing greatly (see Figure 1). This comes as no surprise. Recent advances such as multi-board systems, flex-rigid confirmations, IC-to-board package interfaces, and other innovations add new layers of complexity to product design.

The multi-discipline design challenge

One important result from rising complexity is the transformation of traditional design and development processes into multiple-discipline, multi-domain endeavors that involve more design stakeholders with many different points of view. Some of the new entrants to the process include:

• Analysts who solve electronic power distribution and signal integrity

• Specialists who develop the product’s chip packaging

• Experts who assess the manufacturability of the final design (Design For Manufacturing – DFM)

Adding more stakeholders to the process is, of course, another added layer of complexity because these larger teams are working together in new ways within rapidly evolving workflows. Developing high-quality smart devices requires new technology that makes it easier for these larger and more diverse teams to collaborate.

Why progressive manufacturers have huge competitive advantages

The rise of smart, connected devices is dramatically changing how manufacturers work. One big question that arises when manufacturers consider changing trusted workflows is: will it be worth it?

In a recent study of manufacturers, researchers looked at outcomes based on how “progressive” the organization was. In other words, how much did the manufacturer rely on new IT systems instead of established ones? The study split the respondents into three groups: most progressive, moderately progressive, and least progressive.

The study revealed two very important differences between the three groups:

- Spending less for success

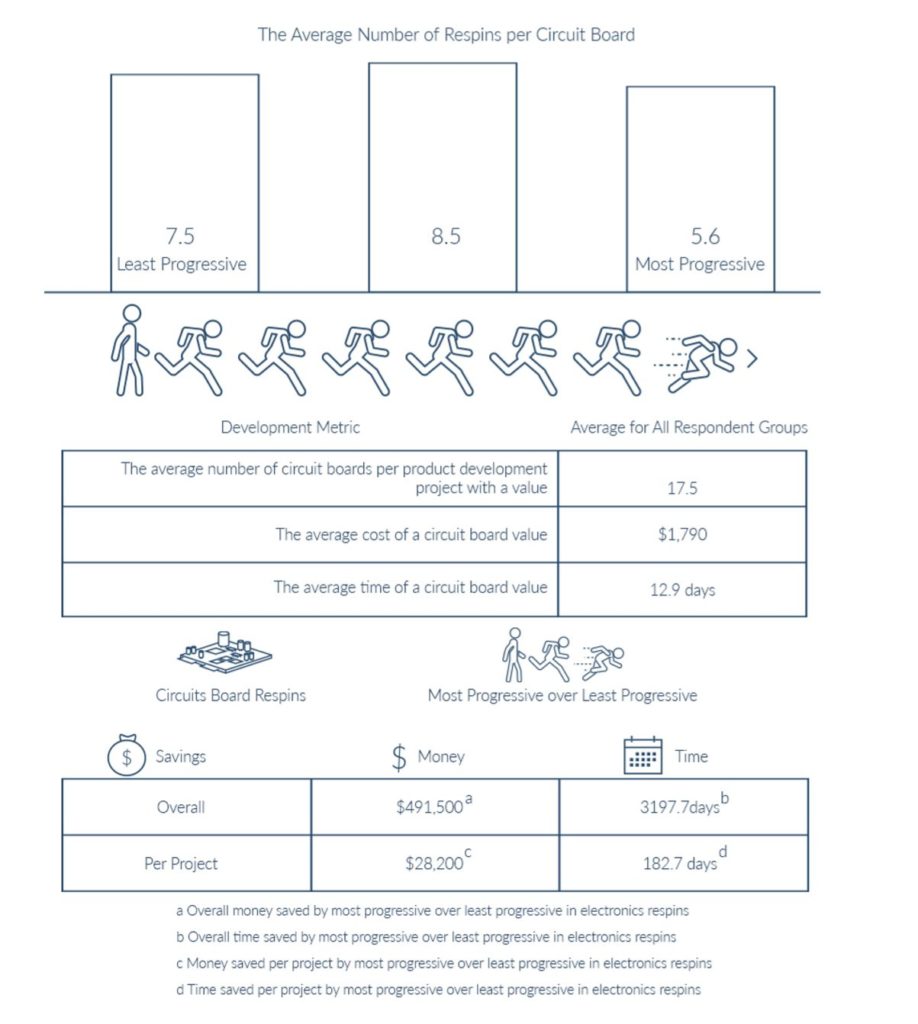

The most progressive companies spend an annual average of $1,038,000 less than the least progressive companies on prototyping and testing, change orders, and PCB respins (see Fig. 3). They also save $491,500 per project and 183 days per project annually by executing fewer PCB respins. This information seems to confirm that adopting new technologies does, in fact, pay off. - Embracing a hybrid approach.

The most progressive companies use cloud-based electronics CAD applications at a significantly higher rate than the two other groups, but not in isolation. Some use file-based, locally installed applications in addition to cloud-based tools, while others use electrical CAD applications connected to on-premise servers. This hybrid approach is not considered a best practice because it can make workflows more complex. However, these results demonstrate that the practice can work when manufacturers use new technology to keep everyone on the same page.

Leveraging cloud solutions to streamline product development

Manufacturers are integrating more circuit board systems into smart products. Often, more circuit boards can mean more problems, such as faults, overheating, and signal integrity issues. To solve these issues, manufacturers use a more collaborative approach to share the digital definition of a circuit board and allow all stakeholders to work on the same design seamlessly.

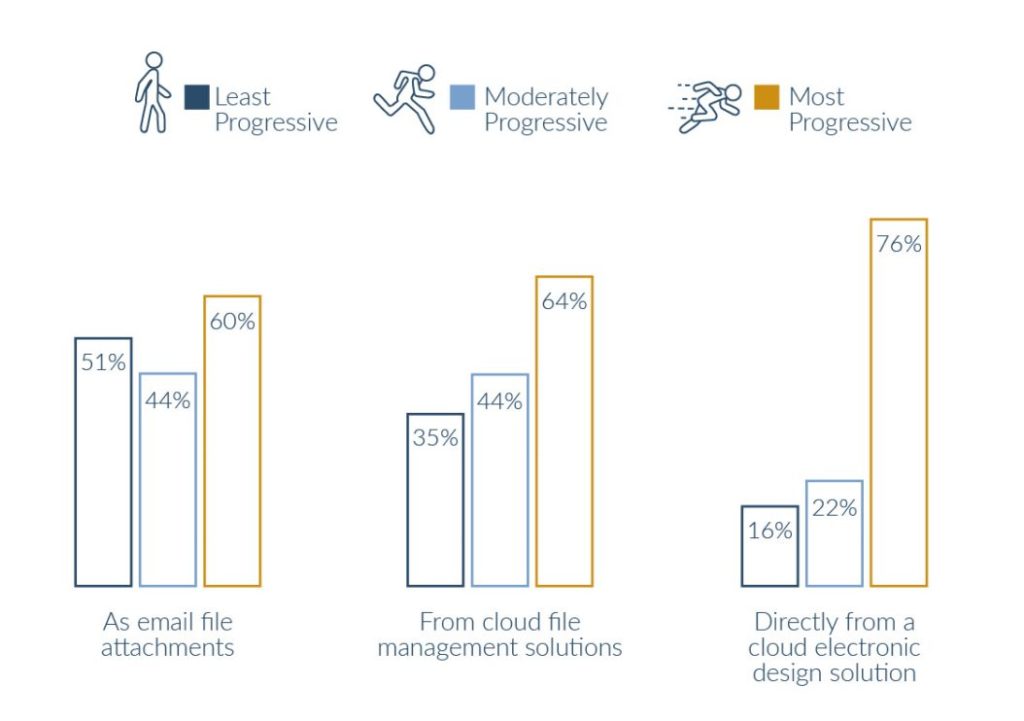

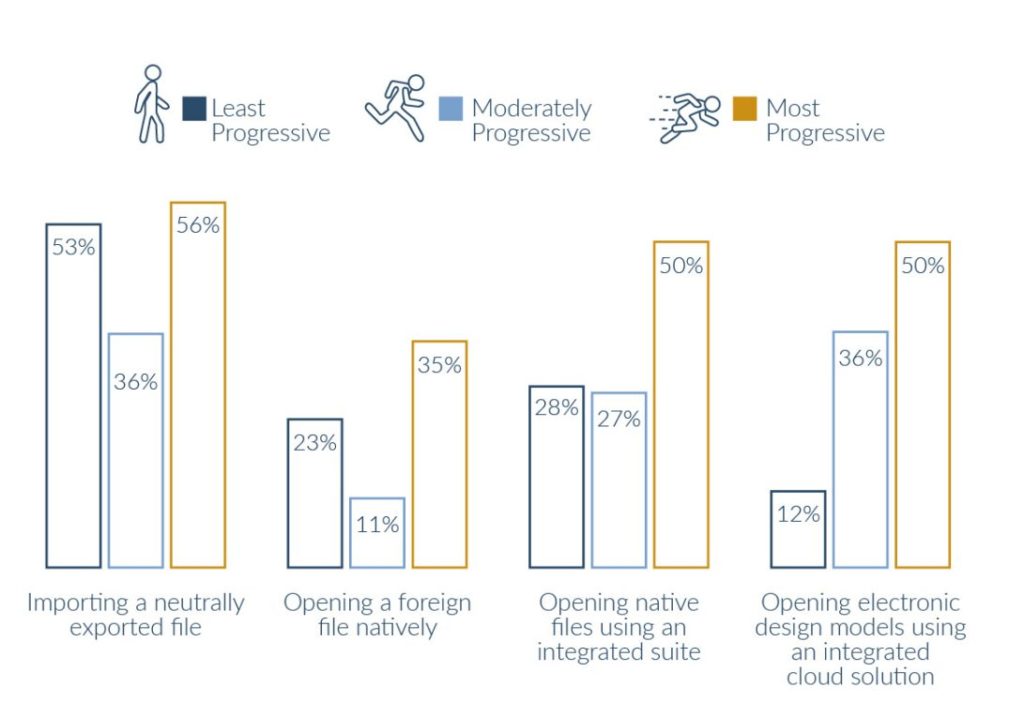

Traditional email file-based strategies tend to fall short. Emails are easily lost or deleted. Design files attached to emails quickly become outdated, creating problems with version control and running the risk of engineers working on obsolete versions. This is why the most progressive manufacturers rely on a mix of file-based, locally installed, and cloud-based solutions to share files while keeping everyone in sync (see Fig. 4).2

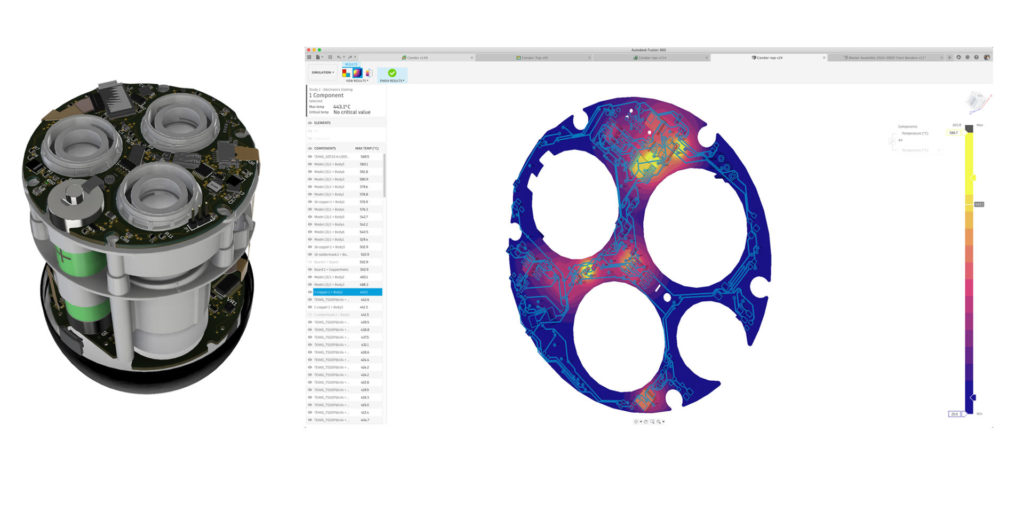

One of the most critical points of collaboration is between mechanical engineers and electrical engineers. According to recent research, the most progressive organizations use cloud-based solutions to share definitions between electrical and mechanical engineers. This helps ensure that electrical components fit within the product’s enclosures and facilitates fluid cooling analyses to prevent overheating and mitigate other risks.

Enabling cross-team collaboration

Cloud-based solutions also make it easier for information to flow freely between mechanical and electrical engineering teams as design modifications occur. Manual file-based export and import exchange systems are unsuitable. Engineers can’t see what has been changed from the prior iteration. To avoid confusion, they may wait until late in the development cycle to exchange ideas. However, this tactic often leads to costly project delays.

The exchange of design modifications with a cloud-based solution is much more frictionless. For one, it allows mechanical and electronics engineers to share designs earlier and more often. Additionally, it improves the product development lifecycle and prevents costly late-stage changes and delays (see Fig. 6).

Every smart device manufacturer will have a slightly different process for product design and development. However, all manufacturers can benefit from three simple recommendations:

- Understand whether and how increased design complexity is affecting the product development lifecycle.

- Evaluate the impact on time and cost of respins with the current process.

- Consider augmenting electrical CAD applications with cloud solutions to facilitate design sharing and collaboration.

Ready to see how cloud-based tools can positively affect your workflow? Check out Fusion 360, the most unified cloud-based multi-discipline development platform for PCB, MCAD, CAM, data management, simulation, and collaboration.

Sources:

1. Lifecycle Insights’ 2020 Engineering Executive Strategic Agenda Study

2. Lifecycle Insights’ 2020 Product Development IT Ecosystem Benchmark Report