This post is also available in: Deutsch (German)

Whether your manufacturing team is the dedicated department for your entire organization or a job shop serving a wider range of customers, there are some common challenges to running an efficient and profitable operation. The underlying problem is one of limited time. If time were not an issue, every project could receive unlimited attention and resources from manufacturing departments or job shops.

This is, of course, not the reality we all share. Time is extremely scarce and operating at maximum efficiency is paramount to staying competitive.

In this article, we’ll take a closer look at the top four challenges manufacturing departments and job shops face and how choosing the right manufacturing software can help your team unlock its full potential for speed, productivity, and quality.

1. Reducing Delivery Time

It’s the first question every customer wants to know: how soon can I get it? When will my parts be ready? Pressure to condense delivery schedules is unrelenting, for good reason. Every minute teams can save is another minute available for finishing another project. But it’s easier said than done, especially for more complex parts.

Automation offers a proven way to speed up design and manufacturing processes. Turning manual steps into automatic ones saves time in the moment and makes these processes more consistent and repeatable. This further reduces the risk of errors, saving time that you would normally spend on rework.

Fusion 360 includes a range of automated programming tools to reduce delivery time. One of these is hole recognition, which detects hole profiles and programs them automatically. This feature dramatically speeds up decisions that a human would have previously made. As an added benefit, automating hole recognition delivers the same output no matter who is programming the machine. Now you can have more flexible changeovers without losing any consistency.

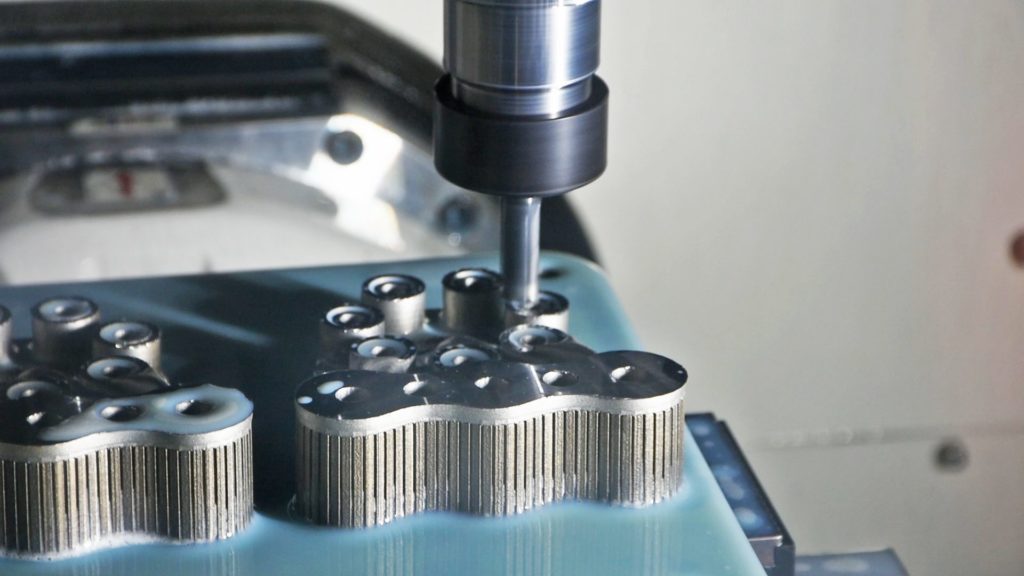

Toolpath operations such as Steep and Shallow automate finishing of freeform surfaces by automatically detecting the surface slope and applying the optimal strategy. Even as parts become more complex, automatic collision avoidance ensures parts are machined with the full range of 5-axis capabilities. This lets you to use shorter, more rigid tools that deliver a higher quality finish.

Built-in collaboration tools can further reduce delivery time because CNC programmers are automatically notified if a new version of the part is available. Toolpaths can be quickly regenerated for the new design, saving time on extensive rework or reprogramming.

2. Maximizing CNC Utilization

The saying goes, if the machine’s not turning, you’re not earning. Manufacturing departments and job shops want to ensure that every machine is used to its fullest extent, at optimal efficiency. This helps you achieve the best ROI.

This dynamic is more critical for your more expensive machines, namely the 5-axis ones typically producing the more complex parts. The stakes are higher in every respect with these machines because any error — in the program, execution, or part — is much more expensive to fix.

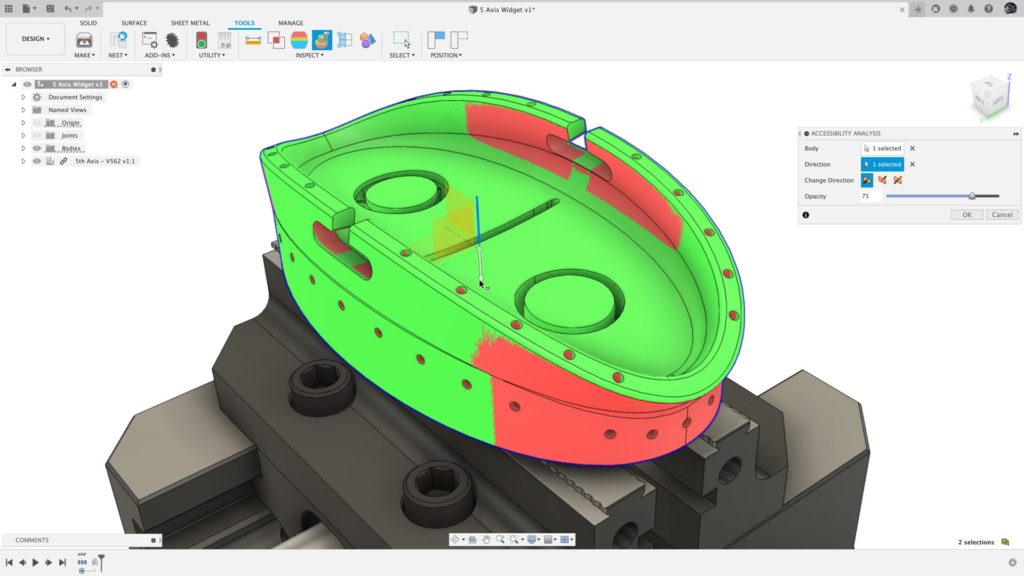

Fusion 360 helps manufacturing teams produce safe, smooth, and predictable NC code that maximizes spindle uptime. It starts with accessibility analysis shading that creates a quick visual reference and indicates whether a part can be fully machined from a single direction. This feature speeds up decisions that need to be made about orienting and fixturing the part so you can start machining sooner.

To reduce the fixturing cost and help you produce parts with fewer setups, multi-axis positional machining, such as 3+2, is effective and easy to use. Tool axis directions are easy to select and calculate rapidly with efficient patterns and ordering options for multi-part machining on tombstones.

For the most complex parts, Fusion 360 ensures the use of shorter, more rigid tools to reduce vibration and improve surface quality during finishing. This is accomplished with a wide selection of toolpath options and tilting methods such as lead, lag, and sideways lean. These options also mean you can cut with the side of the tool and take advantage of its full flute length.

Automatic collision avoidance is vital for maximizing uptime. With Fusion 360, parts can be programmed with a primary tool direction. Vertical starts with the typical Z-axis tool alignment. To and From a point or curve point the tool axis towards or away from selected geometry. If a collision is detected between the part and the tool or holder, the tool automatically tilts away from the part. Behind the scenes of this feature, intelligent smoothing helps avoid any sudden and erratic machine motions while the tool axis limits control of how far each tool can tilt.

These features can be beneficial in a wide variety of situations for job shops and manufacturing departments alike. Perhaps your CNC programmers are switching to a newer, more powerful machine from an older but trusted model. Or a junior programmer needs to start programming more complex parts. They essentially shorten the learning curve, allowing programmers to gain proficiency and reach peak productivity faster.

3. Improving Part Quality

With all of this talk of producing parts faster and more efficiently, it’s important to take a breath and note that any speed improvement will be meaningless if it leads to poor part quality. Any quality issue will compromise your manufacturing department’s profitability. Worse yet, if those issues persist, they can damage your reputation in the industry. So maintaining quality is a constant challenge.

This is why Fusion 360 includes features focused on maintaining high part quality and consistency. Namely, spindle-mounted probing operations that allow you to perform automated setup and part verification.

For starters, setup includes all of the manual work required to place stock material on the machine and locate the work coordinate system origin. Doing this manually requires carefully jogging the machine and clocking the location to get the most accurate position. This is not only difficult and time-consuming, but it can vary from person to person. This process only get more complex when machining castings or other partially manufactured components.

With Fusion 360, setup, programming, and verification on the machine are one experience. You can quickly and accurately set up and check your stock material, in process components, and finished parts directly on the machine and then create the necessary toolpaths. All without leaving Fusion 360.

For cases where it’s difficult to align parts with traditional methods, Part Alignment offers a fast and straightforward workflow. During part setup, the measurement sequence is post-processed as NC code and run on the machine. The results are read back into Fusion 360 to generate part alignment automatically. This is especially useful for irregular, non-prismatic parts, such as castings or additive parts that are difficult to locate manually. It’s also beneficial when machining larger, heavier parts that are physically difficult to maneuver. Because the process is automated, it is consistent from programmer to programmer.

Another point of vulnerability for part quality happens when you have to take the part off the machine for inspection. If or when it’s time for subsequent operations, the part must be repositioned again. This is difficult to repeat exactly and can result in inconsistencies or accuracy problems, both of which can affect part quality.

With Fusion 360, you can complete part verification without removing the part, so you can check part accuracy before continuing machining or final inspection. You not only avoid the risk of repositioning the part, but you detect unexpected variation and address it sooner.

4. Filling the Skills Gap

The skills gap affects manufacturing departments and job shops differently, but this challenge is always in the background. You may have a skills gap because your shop is growing quickly and adding new people with less experience. Or you may have skilled team members retiring and taking a great deal of institutional knowledge with them.

Either way, the problem is one of knowledge transfer. Ideally, you want to find ways to capture the collective experience and intuition of your most skilled team members and make that information more accessible to everyone in the shop.

Collaboration in the shop often happens in spite of, rather than because of, the software used. Fusion 360 can help with this challenge by changing the way manufacturing teams store and share data and best practices.

For example, Fusion 360 allows you to store important manufacturing details and best practices as machining templates that you can share across the entire department or shop. Access to proven templates improves programming consistency for a wide range of jobs. It also allows less-experienced workers to reach peak productivity sooner.

All of this data is stored and shared in the cloud. Connected access makes it easy to get the information you need wherever you are, whether on a desktop or mobile device.

Cloud collaboration also improves workflow among designers, engineers, and machine operators in manufacturing departments and job shops. For example, when the design department releases an updated design, the manufacturing department can access the model in the cloud and start preparing it for manufacture. Shared assets like fixtures, tools, post-processors, setup sheets, and even NC code can be stored in the cloud too.

This way, everyone in the shop — no matter how experienced — has easy access to the data they need to work more efficiently. Programmers can share setup sheets with operators. Operators can update cloud tool libraries for programmers. Designers can communicate design changes to programmers. Assembly teams can receive instructions on fixture assembly. And everyone can be confident they are looking at the most recent data.

Experience Fusion 360

As a cloud-based design, engineering, and manufacturing platform, Fusion 360 gives manufacturing departments and job shops a better way to address these and many other challenges. One of the most important aspects is the Machining Extension, which extends the tools available to engineers and operators to include powerful features on a flexible basis, so you only pay for what you need.

Learn how Fusion 360 can help your manufacturing department or job shop run more efficiently in this webinar or on our site for Manufacturing Departments. Then, download Fusion 360 today.