The Morandi Bridge in Genova, Italy was originally built in 1967 and served as a connector between Italy and France for over 50 years. In August 2018, a section of the bridge tragically collapsed during a storm because it structurally couldn’t handle the weight of modern-day traffic needs, leading to 43 deaths. Due to the bridge’s daily importance, it was clear a new bridge would need to be built quickly. Renzo Piano and PERGENOVA were enlisted to design and build the new Genova San Giorgio Bridge, and it was to be completed in just 15 months to meet demand. On high alert to avoid another tragedy, the team knew they would need to employ a structural health monitoring system to ensure the continued safety of travelers and commuters for years to come.

Enter Somni Solutions, a Netherlands-based company that specializes in designing and manufacturing fiber optic sensors. Somni Solutions met this unique challenge by designing sensors that are able to measure any changes in the position of the bridge’s pillars at a rate of 2,000 times per second. They designed, engineered, and prepped these fiber optic sensors for manufacturing all using Fusion 360.

The sensors provide constant monitoring, allowing engineers to perform predictive maintenance and ensure they are aware of any notable shifts in the bridge’s physical orientation. “Every structure has its own unique set of behaviors,” explains Rik Knoppers, COO of Somni Solutions. “If you add sensors to a structure, you can monitor those behaviors and tell if it is changing because of bad maintenance or hidden damage.”

Unlike regular sensors, Fiber Optic Sensors don’t require coper wiring, frequent maintenance, or batteries, and they are much more affordable to install. The tilt and acceleration-measuring sensors are built from one mono-block of steel, which also reduces manufacturing time and materials. “Electric temperature sensors have about 90 soldering locations, but our sensors are made from only one block of steel, one fiber, and two attachment points,” explains Bastiaan Meulblok, System Engineer at Somni Solutions. The sensors are so durable that they can last around 30 years.

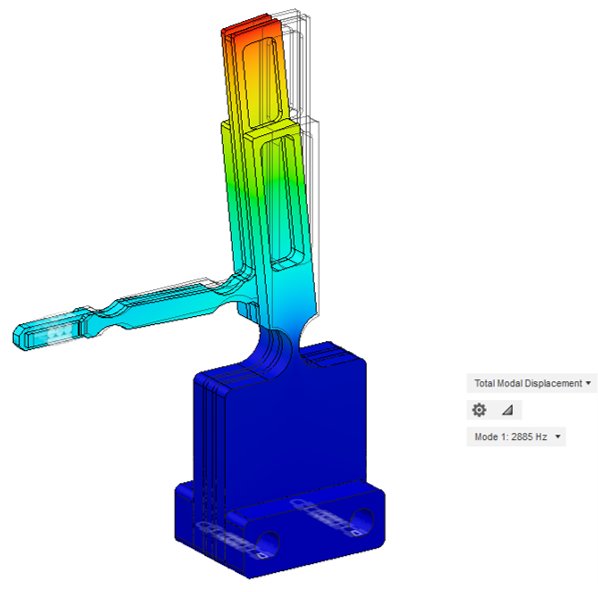

Fiber optic sensor simulation example in Fusion 360.

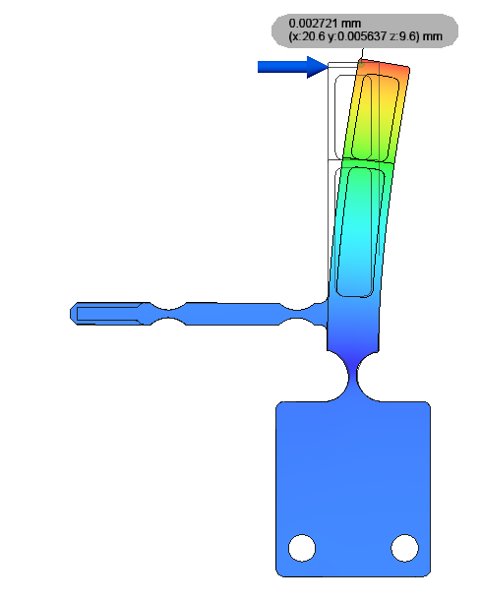

Somni Solutions designed the sensors in Fusion 360 from initial CAD models to a full FEM analysis. “We use Fusion 360’s simulation capabilities to do static and dynamic analysis to predict the sensitivity and behavior of a sensor. The stretching of the sensors’ fibers is often below micrometers, so we have to be very accurate and precise in our process and measurements,” says Meulblok.

The second step of the above simulation example.

Somni Solutions needed to work fast in order to meet the accelerated timeline of the new bridge, and nothing is faster than working on the cloud. “One of the downsides of other modeling software is that integration onto the cloud is a very slow process, and professional licenses are extremely expensive,” says Knoppers. “Fusion 360 is a whole different ballgame. The pricing is much more competitive, it’s much easier to add or get rid of an extra account, and you have the whole package, including cloud simulation, available at your command.”

At the end of the day, safety always comes first. Knoppers and Meulblok stress the importance of adopting fiber optic sensors as a safe structural health monitoring system for large weight-bearing structures. “If you use sensors for a structure like the Genova San Giorgio Bridge, you can do less maintenance, while still being confident that your structure is safe and in good health.”

The Genova San Giorgio Bridge opened last month and is currently in use.