Standard cost versus actual cost. These are both popular methods when determining actual manufacturing costs. Let’s dive into both to help determine what solution is best for you.

Selecting the appropriate costing method is crucial for success in the dynamic world of manufacturing. Today, the landscape of costing solutions is dominated by two primary approaches—standard costing and actual costing—but what sets them apart?

The intricacies of standard cost versus actual costing

Costing methods are essential for understanding the financial impacts of a business, particularly during the production process where informed decision-making is pivotal for effective operations. In product design and manufacturing, two main costing methods are often considered: standard vs actual cost.

Standard costing

In contrast, standard costing uses predetermined costs for materials, labor, and overheads that are based on historical data, industry benchmarks, or estimated costs. This method simplifies accounting and budgeting by providing a consistent framework for cost analysis.

Standard costing is particularly useful for routine and repetitive manufacturing processes where costs are predictable. Allowing for easier budgeting and variance analysis, it enables managers to easily identify inefficiencies and areas for cost reduction. However, the drawback of standard costing lies in its potential for inaccuracy in rapidly changing market conditions as well as during the introduction of new products.

Actual costing

The actual costing method encompasses tracking the costs of materials, labor, and overheads as they occur. By doing so, actual costing provides a detailed and accurate picture of production costs, reflecting real-world conditions. The detailed nature of this method makes it a valuable solution for companies seeking precision in their cost analysis.

However, it’s important to note that actual costing is a complex and time-consuming solution, requiring meticulous record-keeping. Due to this, maintaining this method can be especially difficult in environments with fluctuating prices or varying production levels.

Both costing methods have their merits and limitations—the choice between them depends on various elements such as the nature of the manufacturing process, cost stability, and the level of detail required in cost analysis.

Autodesk’s role in standard cost vs. actual cost

Autodesk Fusion Operations is a product management and production tracking software that allows you to reduce waste and costs, shorten lead times, and minimize shop maintenance.

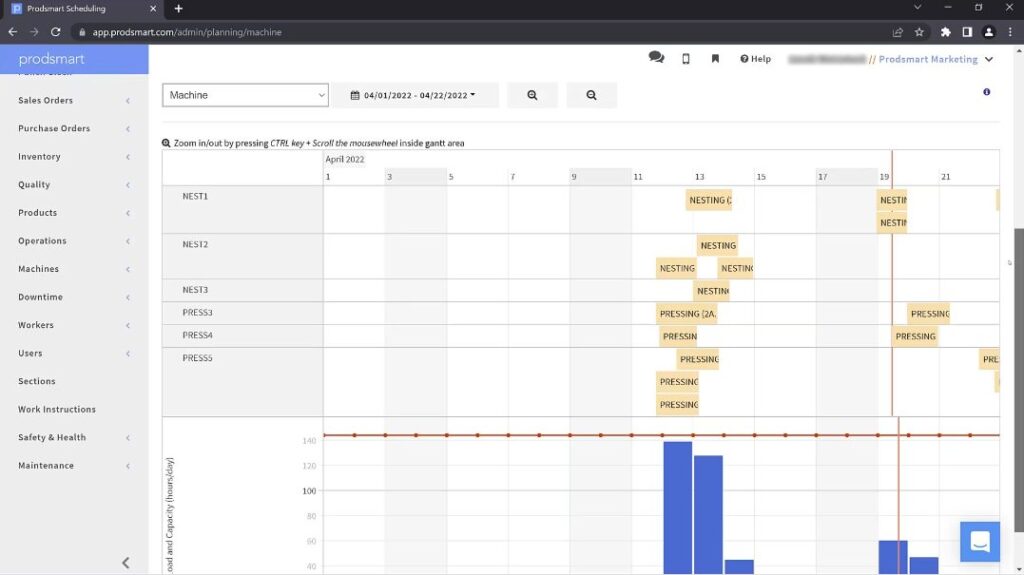

With access to real-time data through an operations dashboard, you can track and analyze all aspects of your operations including orders, workers, materials, machines, maintenance, waste, time, and costs in real-time. You can even build custom parameters to review your data by period, worker, section, machine, product, and operation.

Further, you’ll gain access to product visibility where you can

track and analyze your entire production flow, from orders and workers to materials, time, and costs, with real-time production tracking dashboards and reports fed directly from the shop floor through mobile devices.

Manage your costs more effectively and take your production to the next level with Autodesk Fusion Operations.