This post is also available in: Italiano (Italian) Deutsch (German)

Stewart-Haas Racing is a championship-winning NASCAR organization that competes in two top national touring series. Learn how the team could lightweight the brake pedal using Autodesk generative design in Fusion 360.

Stewart-Haas Racing has one primary mission: Win more races. The championship-winning NASCAR organization constantly explores new design and manufacturing innovations to keep their teams in the lead — always focusing on safety, performance, and weight reduction.

In partnership with Autodesk, Stewart-Haas Racing decided to try and lightweight the brake pedal, as this is one of the most critical parts of top driver Cole Custer’s No. 41 Ford Mustang.

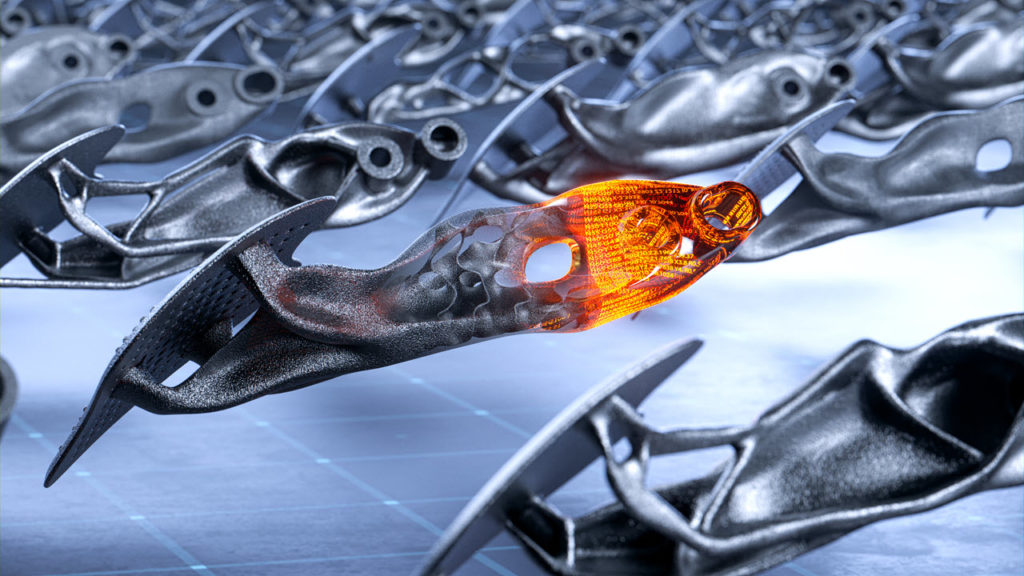

Optimizing with generative design

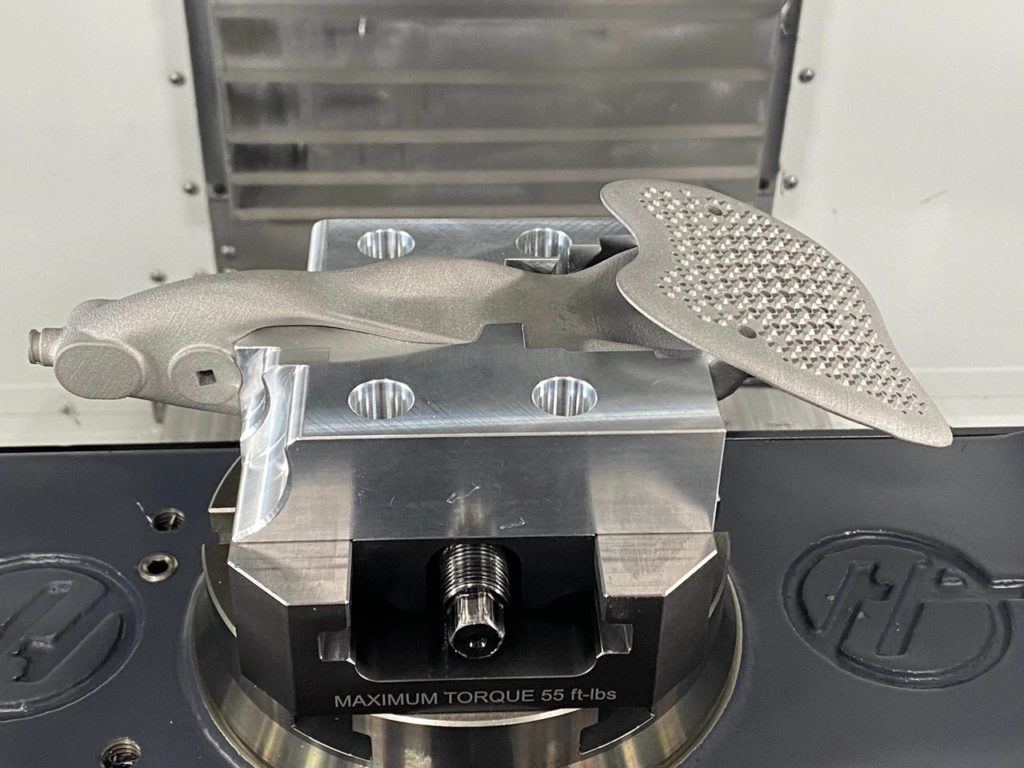

The team used traditional manufacturing methods to design the existing brake pedal. Eventually, they had exhausted the options for any additional weight savings. With Autodesk Fusion 360, the team used generative design to discover multiple new designs with weight and safety in mind. They decided on their top choice for simulation testing and manufactured it with Renishaw’s Ren 500Q quad-laser powder bed metal printing 3D system.

The team tested the pedal in-house to simulate normal braking events over multiple race distances, representing 3000 laps of braking. “The pedal withstood all of those loads and cycles flawlessly,” says Walter Mitchell, Engineering Integration Manager, Stewart-Haas Racing.

Stewart-Haas Racing realized a 32% reduction in weight and a 50% increase in stiffness for the new brake pedal. It only took two months to complete from start to finish, and it was delivered within two weeks of the needed race date.

“Being able to utilize both Autodesk generative design and Renishaw’s metal printing capabilities will unlock doors that were previously unavailable to increase performance, reach higher speeds, and decrease lap times,” says Mitchell.

Learn more about Stewart-Haas Racing’s journey with generative design here.

Explore unlimited ideas

Are you ready to improve product performance, increase productivity, and lower costs? Get started with Fusion 360 for free today.