& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

6 min read

“What once was only possible for software is now

possible for embedded hardware: without a significant amount

of effort, you can make a smart physical device, test it out,

and validate the idea with users.”

– Jon McKay, Co-Founder of Technical Machine

A year ago, Jon McKay, Tim Ryan, and Jia Huang were working on a senior capstone project at the Franklin W. Olin College of Engineering in Needham, Massachusetts. Working to harness the information that people store online (Spotify playlists, Foursquare check-ins, etc.) from their real-world experiences, their team created devices that connected people through an electronic handshake, or crowd-sourced party playlists through the swipe of an RFID card.

“I’m a software engineer,” Jon explains, “and I’m passionate about bringing the Web to physical devices. Armed with Node.js and Heroku, I could whip up a web application in a matter of minutes. Now, all I had to learn was how to make a physical device that could connect. With devices such as Arduino and Raspberry Pi, it should have been just as easy.

“But it wasn’t.”

With that, the three set out to solve the problem by founding the company Technical Machine and creating Tessel, a wireless microcontroller that runs on JavaScript. Tessel gives programmers the opportunity to reach out from the Web and control physical devices; we at Autodesk partnered with them to use Fusion 360 to create a variety of hard cases for Tessel that protect, personalize, and stage the microcontroller for a particular use.

Original Tessel Prototype Current Tessel microcontroller in a 3D-printed case

“I got started with Technical Machine because I thought

hardware development needed to be brought into step with

the way the Internet works. I think what we’ve created is

the next step in the hardware revolution: hardware

that speaks the language of the web.”

– John McKay

Jon, Jia, and Tim expanded their team of three Oliners to a team of six Oliners, including Eric Kolker to help develop the electrical engineering of Tessel and Kelsey Breseman to “make sure the team doesn’t overlook small details like paying taxes or having a marketing plan.” Together, they formed a crowd-funding campaign with Dragon Innovation to bring to life a wireless “tessellation” of a microcontroller with modules that easily attach for sensor input and control output.

As they explained it in their Dragon Campaign: “Developing for Tessel is just like web development: write your JavaScript code and deploy it with a simple push command – just like pushing to a server . . . Tessel’s module system makes it easy to add capabilities to any project without soldering. Just like Node’s module system, each Tessel module encapsulates a specific functionality that can be added to the board, such as RFID, microSD, or a servo.”

“We’ve designed Tessel for usability and modularity.

We’re aiming for a device that’s more like a PaaS, where

you can push code without extensive configuration

or drivers. (Of course, our firmware will be open

for any modification you’d like.)”

– Kelsey Breseman

Only a few hours after launching their campaign, Technical Machine was funded beyond their goal of $50,000, and ended the campaign with 393% of their goal funded – still one of the most successful crowd-funding campaigns in Dragon history.

Autodesk first connected with Technical Machine while they were setting up shop at Greentown Labs, an incredible incubator space in Somerville, Massachusetts. Autodesk is a sponsor there (through our Clean Tech Partner Program), and we were inspired by the team’s efforts to bring the Internet of Things to life with their innovative work with Tessel.

With backgrounds in electrical and software engineering, the folks at Technical machine were already great at conceiving, developing, and producing their microcontroller. They also saw a definite need among their end users for cases and accessories for their end users — yet designing, manufacturing, and selling cases for the controllers would mean a drastic and burdensome shift in business strategy, logistics, and process for Technical Machine.

We were able to partner with them on a project to use Fusion 360 to create unique and customizable cases, stands, and platforms for the microcontroller. Instead of having cases manufactured, the team developed an elegant solution that carried on their mission of designing in the virtual and producing in the physical. With their audience of makers and prototypers in mind, the team decided to develop some basic cases and provide those files to be downloaded, customized, and easily built by users.

Fusion 360 made it easy to connect designers at Autodesk and Technical Machine. It’s also free to enthusiasts, students, and early-stage start-ups who would be using Tessel in their projects, so anyone has access to editing. On top of that, projects that users are working on can easily be shared to the Fusion Gallery, where others designers and engineers can connect with innovative tools like Tessel.

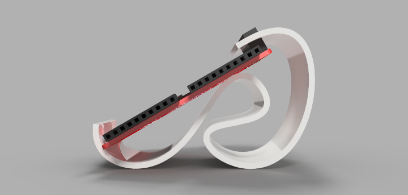

Tessel users will need everything from full-enclosed protective cases to functional stands that interface with external structures, to stylish covers with personalized features. In our collaboration, we created a series of cases using Fusion’s parametric modeling and organic sculpting environments. The result was an accurate 3D model of Tessel around which the customer can design a custom case, stand, or accessory.

Here are some sample designs:

Raw Fusion files (.f3d) will be provided to all of Tessel’s customers through GrabCAD so they can easily be downloaded and installed. Customers can quickly download Fusion 360 (typically in less than 10 minutes), customize a model, and within minutes start 3D-printing or laser-cutting. We think it’s really going to be an engaging, freeing design experience for end users.

You will soon find all of the designs at GrabCAD and at a website Technical Machine is setting up to provide links, Fusion-generated renders, and learning materials for these cases.

Meanwhile, people are already using Tessel to create awesome things – from servo systems to pulse sensors to art installations. Technical Machine has a great projects page, much like Fusion’s Gallery, where they’re creating an engaged community that’s sharing ideas and inspiring innovation. And now these same people can take their projects to the next level with customized cases and hardware to frame their systems. I’m so excited to see how people will use Tessel and Fusion 360 in the future, and hopefully see their designs in our Gallery and Tessel’s project page!

Technical Machine is working on a platform to scale up Tessel projects with custom circuit boards; clients will be able to order a batch of circuit boards with their modules integrated into one board and with their code preloaded on the microcontroller. They can beta test using the boards, then improve them by tracking aggregate usage data and updating the firmware wirelessly. “Tying this new world of Internet-enabled devices into the vast store of information we already keep on the cloud is a logical next step,” McKay says. “We don’t have to tell our new devices what to do because – through their connection with our constantly-updating online presence – they will already know.”

Feeling inspired? Check out all that Technical Machine has to offer here, and stay tuned for our future collaborations!

*Special thanks to Tanner Reid,Technical Evagelist, for contributing this story.

Technical Machine has set out to empower the Internet of Things with a microcontroller that allows web developers to reach out of the web and into the physical world. In the same spirit, the team needed a new way to design and deliver cases and stands for Tessel, and we’ve partnered with them to do just that.

" class="bg-charcoal-900 rounded-full w-6 h-6 items-center justify-center flex mr-2"> Share on Twitter Share on linkedinBy clicking subscribe, I agree to receive the Fusion newsletter and acknowledge the Autodesk Privacy Statement.

Success!

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.